Turning tools

Turning tools are essential in the world of machine shops. They are the key to precise, high quality machining of various materials.

Turning tools are tools used in machine tools, such as lathes, to remove material from a workpiece in order to obtain the desired shape. These tools can be manual or automated (such as those used in CNC lathes) and come in different shapes and sizes depending on the type of machining to be performed.

Turning is an essential process in many industrial and mechanical applications. Turning tools serve to:

- Create cylindrical surfaces: Ideal for machining shafts, screws and other cylindrical components.

- Performing threads: Used to create internal and external threads on various materials.

- Drilling and reaming: In addition to turning, many tools can be used for drilling and reaming.

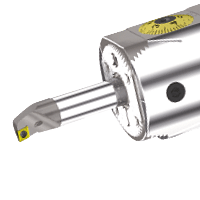

- Internal machining: Specific tools allow machining inside hollow workpieces, such as internal turning.

The correct use of turning tools is crucial for optimal results. Here are some guidelines:

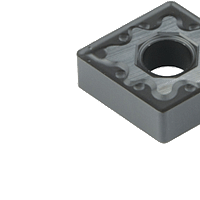

- Material selection: Select carbide or high-speed steel tools depending on the workpiece material.

- Parameter setting: Set cutting speed, feed rate and depth of cut correctly.

- Maintenance: Keep tools sharp and in good condition to avoid machining defects.

The use of high-quality turning tools offers numerous advantages:

- Accuracy: They allow extremely precise machining, which is essential for critical mechanical components.

- Efficiency: Reduced machining times thanks to optimised parameters and appropriate tools.

- Versatility: Suitable for a wide range of materials, from hard metals to technical plastics.

- Durability: High-quality tools have a long service life, reducing replacement and maintenance costs.

Frequently Asked Questions

What are the best CNC turning tools?

CNC turning tools are often made of tungsten carbide or ceramic, materials that offer superior strength and durability. It is important to choose tools that are compatible with your CNC lathe and specific to the material to be machined.

What is the difference between internal and external turning tools?

Internal turning tools are designed for working inside hollow workpieces, while external turning tools are used for machining on external surfaces. Their shape and size vary according to specific machining requirements.

Are metal turning tools also suitable for non-metallic materials?

Many metal turning tools can be used on non-metallic materials, such as technical plastics and composites, but it is necessary to adjust the machining parameters and choose specific tools for optimal results.

In conclusion, turning tools are essential for any machine shop that wants to achieve precise, high-quality machining. With proper selection, use and maintenance, these tools can significantly improve productivity and the quality of finished products.