Abrasive brushes

Abrasive brushes are essential tools in machine shops for a wide range of finishing and cleaning tasks. These tools, also known as abrasive fibre brushes or abrasive bristle brushes, are designed to remove material from the surface of metal and non-metal workpieces, ensuring a precise and uniform finish.

Advantages of Abrasive Brushes

- Versatility: Abrasive brushes are suitable for a variety of applications, including deburring, cleaning, satin finishing and surface preparation. They can be used on a variety of materials such as steel, aluminium, plastic and wood.

- Efficiency: Due to their ability to quickly remove unwanted materials, abrasive brushes increase the efficiency of machining processes. This saves time and reduces operating costs.

- Precision: Abrasive brushes allow you to work with great precision, removing only the desired amount of material without damaging the surface of the workpiece. This is particularly important in finishing operations where high surface quality is required.

- Durability: Made of durable materials such as silicon carbide or aluminium oxide, the abrasive brushes guarantee a long service life, reducing the need for frequent replacement.

Features of Abrasive Brushes

- Abrasive Materials: Abrasive brushes are made from different types of abrasives, including silicon carbide, aluminium oxide and ceramic. Each material offers unique properties that make them suitable for specific applications.

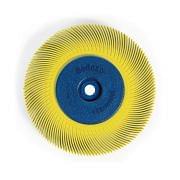

- Formats and Sizes: Available in various sizes, the abrasive brushes can be cylindrical, conical, disc or cup-shaped. The choice of size depends on the specific application and the type of machine tool used.

- Abrasive Grit: The grit of the abrasive brushes varies from very coarse to very fine, allowing the desired finish to be obtained. Coarse grits are ideal for quick material removal, while fine grits are perfect for polishing and finishing.

- Compatibility: The abrasive brushes are compatible with a variety of machine tools, including drills, angle grinders and computer numerical control (CNC) machines. This compatibility makes them a flexible tool that can be easily integrated into production processes.

In machine shops, abrasive brushes are used for:

- Deburring: Removing burrs created during metal cutting or machining.

- Cleaning: Removing rust, paint and other contaminants from metal surfaces.

- Satin finishing: Creating satin finishes on metal surfaces to improve aesthetics and corrosion resistance.

- Surface preparation: Preparing surfaces for subsequent processes such as welding or painting.

Abrasive brushes are indispensable for ensuring the quality and precision of machining operations, making them an essential investment for any workshop wishing to maintain high standards of production and finishing.