HSS rotary cutters

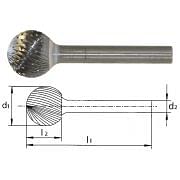

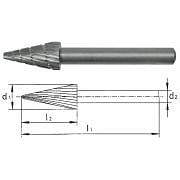

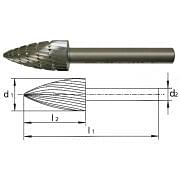

HSS (High-Speed Steel) rotary cutters are essential tools in modern machine shops, used for a wide variety of metalworking applications. Variants of HSS rotary cutters include cylindrical cutters, spherical cutters, end mills and conical cutters, each designed for specific machining requirements.

Advantages of HSS rotary cutters

- High Heat Resistance: HSS rotary cutters are known for their ability to maintain hardness even at high temperatures, making them ideal for high-speed machining.

- Durability: Due to their composition, HSS milling cutters offer longer tool life than other milling cutters, reducing replacement frequency and maintenance costs.

- Versatility: They can be used on a wide range of materials, including steel, cast iron, aluminium and other non-ferrous metals.

- Precision: They allow precise and detailed machining, which is essential for complex mechanical components.

Features of HSS Rotary Cutters

- Material: High Speed Steel, or HSS, is an alloy containing various elements such as tungsten, molybdenum, chromium and vanadium, which give the material its hardness and strength.

- Blade geometry: HSS rotary cutters are available in different blade configurations, such as knurled, serrated and helical, to suit different cutting requirements.

- Coatings: Many HSS cutters are coated with materials such as titanium nitride (TiN) or titanium carbonitride (TiCN) to further improve wear resistance and extend tool life.

HSS rotary cutters are used in numerous milling operations, including shaping, grooving and surface finishing. They are essential in the production of moulds and dies, the manufacture of automotive and aerospace components, and the creation of machine tool parts. Their ability to work at high speeds without losing accuracy makes them indispensable for operations where cutting quality is critical.

HSS rotary cutters are vital tools for any machine shop that needs precision, durability and versatility. Thanks to their advanced features and ability to work on a variety of materials, HSS rotary cutters remain a preferred choice for mechanical professionals. Choosing high-quality HSS milling cutters means investing in tools that guarantee excellent performance and low production costs in the long run.