< Lubricants for machine tools Minimal lubrication systems

Minimal lubrication systems represent an advanced and innovative solution in machine shops, offering an efficient and sustainable approach to lubrication management. These systems are designed to deliver the minimum necessary amount of lubricant directly to the contact surface, minimising waste and improving overall machine performance.

Understanding minimal lubrication systems

Minimal lubrication systems, also known as MQL (Minimum Quantity Lubrication), are a technology that is rapidly emerging in the industrial sector. Unlike traditional methods that use large quantities of lubricants, MQL systems use a mixture of compressed air and a small amount of lubricant, applied directly on the machining area. This approach not only reduces lubricant consumption, but also improves the quality of the finished product and extends tool life.

Advantages of minimal lubrication systems

The adoption of minimal lubrication systems offers numerous advantages. Firstly, it significantly reduces operating costs due to lower lubricant consumption and reduced machine cleaning times. In addition, the use of a minimal amount of lubricant decreases the environmental impact, making the process more sustainable. Another key benefit is increased tool life, as effective lubrication reduces wear and overheating.

Practical applications in machine shops

In machine shops, minimal lubrication systems find application in various machining processes, such as milling, turning and drilling. These systems are particularly effective in high-speed operations, where conventional lubrication may not be sufficient to prevent overheating. The use of MQL in these applications not only improves machining quality, but also results in smoother and more precise surfaces.

How minimal lubrication systems work

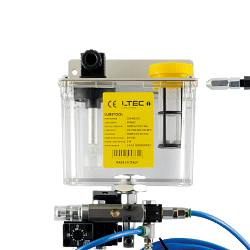

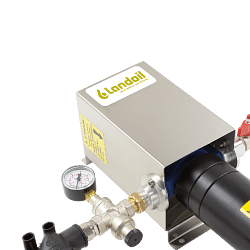

The operation of minimal lubrication systems is based on a simple but effective principle. A dispensing device mixes a small amount of lubricant with compressed air, creating a fine mist that is directed onto the machining surface. This method ensures that the lubricant reaches exactly the point of contact, minimising waste and improving process efficiency.

Implementation considerations

The implementation of minimal lubrication systems requires a careful evaluation of the specific needs of the workshop. It is important to choose the type of lubricant best suited to the material and machining process. In addition, calibration of the system is crucial to ensure that the amount of lubricant dispensed is optimal. Proper installation and regular maintenance are essential to maximise the benefits of these systems.

Frequently asked questions about minimalist lubrication systems

Many industry professionals ask questions about minimalist lubrication systems. One of the most common questions concerns compatibility with existing machines. Fortunately, most MQL systems can be adapted to existing equipment, making the transition simple and convenient. Another frequently asked question concerns the choice of lubricant. It is essential to select a lubricant that is compatible with the material being machined and offers the necessary properties for the specific process.

Conclusions

Minimal lubrication systems represent a significant step forward for machine shops seeking to improve operational efficiency and reduce environmental impact. With their many benefits, including reduced costs, increased tool life and improved product quality, these systems are set to become an essential component of modern machining operations. Adopting MQL technology not only brings economic benefits, but also contributes to a more sustainable future for the manufacturing industry.

Read More Read Less