Lubricants for machine tools

In the world of machine shops, machine tool lubricants play a crucial role. These products not only ensure the proper functioning of machines, but also increase their efficiency and service life.

There are various types of high-performance machine tool lubricants, each with specific characteristics. Lubricants can be oil-based, grease-based or synthetic, and choosing the right type depends on the specific needs of the machine and operating conditions.

- Oil-based lubricants: These are ideal for operations requiring friction reduction and effective cooling. Frequently used in oil-based machine tool lubrication, these products are excellent for keeping contact surfaces smooth and operational.

- Grease lubricants: These lubricants are thicker and offer long-lasting protection against wear. They are particularly useful for applications where the machine is subjected to high loads and slow movements.

- Synthetic lubricants: Known for their excellent heat and oxidation resistance properties, synthetic lubricants for mechanical equipment are ideal for extreme operating environments.

The correct application of lubricants is crucial for best results. First and foremost, it is essential to follow the machine manufacturer's recommendations regarding the type and quantity of lubricant to be used.

Proper machine tool lubrication offers numerous advantages. Among these, the most significant are:

- Reduced friction: A proper lubricant reduces friction between moving parts, decreasing wear and extending the life of the machine.

- Operating efficiency: Well-lubricated machines operate more smoothly and with fewer interruptions, increasing workshop productivity.

- Corrosion protection: Lubricants form a protective barrier against moisture and other corrosive agents, keeping metal surfaces in good condition.

- Heat reduction: Proper lubrication helps dissipate heat generated during operations, preventing overheating and damage to components.

Frequently Asked Questions

What are the best lubricants for machine shops?

The choice of lubricant depends on the specific needs of the machine and operations. High-performance synthetic lubricants and specific machine tool oils are generally considered excellent for machine shops.

How do I know when to change the lubricant?

Regularly monitoring the condition of the lubricant is crucial. Following the manufacturer's instructions and checking for signs of contamination or degradation can help determine the right time for replacement.

What is the difference between oil and grease lubricants?

Oil lubricants are smoother and ideal for reducing friction and cooling surfaces, while grease lubricants are denser and offer long-lasting protection against wear, especially useful for high-load applications.

The importance of machine tool lubricants in machine shops cannot be underestimated. Choosing the right lubricant and applying it correctly are essential to ensure the efficient and long-lasting operation of machines.

-

Water-miscible coolants14 products

-

Neat cutting oil8 products

-

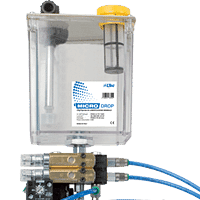

Minimal lubrication systems2 products

-

Oil for guides and slides1 products

-

Drums of hydraulic oil fluid4 products

-

Anti-freeze for machine tools1 products

-

Air coolers4 products

-

Oil separator6 products

-

Powders and absorbents for oil10 products

-

Aspirators for oil mist4 products

-

Accessories for cooling lubricants7 products

-

Protettivi per metalli e stampi7 products

-

Grease and paste35 products