Angle heads

Angle heads are essential tools in modern machine shops, designed to increase the versatility and efficiency of machining operations. Also known as 90-degree angle heads, drill angle heads or milling angle heads, these units allow machining operations to be performed in confined spaces or spaces that are difficult to access with conventional tools.

Angle heads consist of a rotary head and an angle drive mechanism. The heads can be adjusted to work at various angles, often up to 360 degrees, providing flexibility in machining. Power transmission is provided by bevel or worm gears, which allow the tool mounted on the angle head to rotate.

Angle heads can be fitted with standardised attachments such as ISO, HSK or BT, making them compatible with a wide range of machine tools, including drills, milling machines and lathes.

Advantages of Angle Heads

- Versatility: Angle heads allow machining in hard-to-reach positions, increasing the usability of existing machine tools.

- Efficiency: By reducing the need to reposition parts or use multiple machines, angle heads improve the efficiency of the production process.

- Precision: Thanks to their robust construction and high-quality gears, angle heads offer precision and stability during machining operations.

- Space-saving: They allow complex operations to be performed in limited space, reducing the amount of equipment on the shop floor.

Angle heads are used in various sectors of the mechanical industry, from the production of automotive components to the manufacture of industrial machinery. They allow drilling, milling and boring operations in corners that are not accessible with straight heads, such as inside gear housings or other complex structures.

When selecting an angle head, it is essential to consider compatibility with the machine tool and the type of machining to be performed. It is important to choose an angle head with adequate torque capacity and an efficient cooling system to avoid overheating during intensive machining.

Angle heads are a strategic investment for machine shops looking to optimise their production processes, offering a combination of versatility, efficiency and precision. Whether for complex machining or routine operations, angle heads significantly improve the operating capacity of machine tools, making them an indispensable element of any advanced manufacturing environment.

-

Promo

C4715

Presetting KERFOLG EYE TRIM IIfrom €7,140.00 to €8,060.00

Special Price -12%

from €6,280.00 to €7,090.00 -

-

C4901

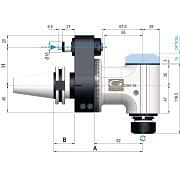

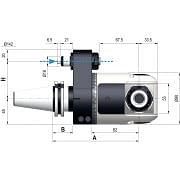

Angle heads with adjustable angles from 0° to 90° GERARDI GMU16 - GMU20from €4,216.00 to €4,516.00 -

New