< Lifting systems Lifting monobeams

Lifting scales are a crucial element in the landscape of machine shops and industries that need reliable solutions for handling heavy loads. These tools, designed to optimise lifting and weight distribution, are essential for safe and efficient production processes. In this essay, we will explore in detail what sling bars are, how they are used, the advantages they offer and answer frequently asked questions on this topic.

What are Lifting Slingbars?

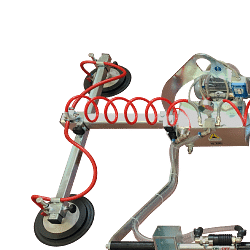

Sling bars are mechanical devices used to evenly distribute the weight of a load during lifting. They consist of a horizontal beam, usually made of steel, with hooks or other attachment devices at each end. They are designed to be used in combination with cranes or other lifting systems, allowing large or irregularly shaped loads to be lifted safely and efficiently.

Use of Lifting Slingbars in Machine Shops

In machine shops, lifting sling bars are used in a wide range of applications. They are particularly useful when handling large components, such as engines, frames or other metal structures. Due to their ability to distribute weight evenly, sling bars reduce the risk of damage to materials and improve operator safety.

Advantages of Lifting Slingbars

The use of lifting sling bars offers numerous advantages. First of all, they improve work safety by reducing the risk of accidents when lifting heavy loads. In addition, they optimise handling times, increasing operational efficiency. Lifting slingbars are also versatile, adapting to different types of loads and lifting configurations. Finally, due to their robustness and reliability, they are a lasting investment for companies.

Types of Lifting Slingbars

There are different types of sling bars, each designed for specific operational needs. Among the most common are fixed-beam sling bars, which are ideal for standard-sized loads, and adjustable sling bars, which offer greater flexibility for variable-sized loads. Other variants include multiple-point sling bars, which are used for lifting particularly long or complex loads, and sling bars with automatic balancing, which automatically adjust to the load's centre of gravity.

How to Choose the Right Slingbar

Choosing the right sling bar depends on several factors, including the type of load to be lifted, the lifting capacity required and the specific operational needs of the workshop. It is also important to consider the characteristics of the lifting system with which the sling bar will be used, ensuring that it is compatible and can support the weight of the load. In addition, it is essential to check that the sling bar complies with applicable safety regulations.

SlingBar Maintenance and Safety

To ensure the safety and longevity of sling bars, regular maintenance is essential. This includes periodic inspection of welds, hooks and other components for signs of wear or damage. It is also important to follow the manufacturer's guidelines for proper use of the sling bar and to properly train personnel in the safe use of these devices.

Frequently Asked Questions about Sling Cross-bar

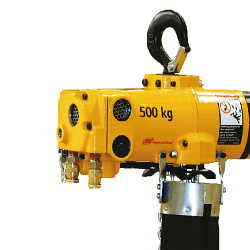

1. What is the typical lifting capacity of a sling bar?

The lifting capacity of a sling bar varies depending on the model and design, but can generally range from a few hundred kilograms to several tonnes.

2. Can sling bars be used outdoors?

Yes, many sling bars are designed to withstand outdoor conditions, but it is important to check the product specifications to ensure that it is suitable for outdoor use.

3. Is it possible to customise a sling bar?

Many manufacturers offer the possibility to customise sling bars to meet specific needs, such as special sizes or attachment configurations.

4. What are the safety regulations for sling bars?

Sling bars must comply with specific safety regulations, such as the European directives for lifting equipment, which establish requirements for design, manufacturing and use.

5. How can I improve safety when using sling bars?

In order to improve safety, it is essential to follow the manufacturer's instructions, perform regular checks and properly train personnel on the correct and safe use of sling bars.

In conclusion, sling bars are indispensable tools for machine shops and industries that need reliable solutions for handling heavy loads. Their ability to improve safety and operational efficiency makes them a valuable investment for any company. With proper maintenance and knowledgeable use, lifting sling bars can provide years of reliable and safe service.

Read More Read Less