Lifting systems

In the world of machine shops, lifting is a crucial aspect that directly affects the safety and efficiency of daily operations. The ability to lift and position heavy loads correctly is essential for maintaining a smooth and accident-free working environment.

Lifting techniques can vary greatly depending on the type of load and equipment available. In general, a combination of mechanical and manual equipment is used to ensure that loads are lifted safely and accurately.

Among the most common techniques are the use of cranes and hoists, which allow heavy loads to be lifted with minimal physical effort. In addition, lifting platforms offer a versatile solution for working on machine or vehicle components. The choice of the most suitable technique depends on the specific operational needs of the workshop and the characteristics of the loads to be handled.

Among the main lifting tools are:

- Cranes and Hoists: Used to lift heavy loads with precision. Hoists can be manual or electric, depending on the weight and frequency of use.

- Hydraulic Platforms: Provide stable and adjustable support for lifting objects to different heights, improving access and manoeuvrability.

- Jacks and Supports: Used to lift vehicles and other heavy structures, allowing maintenance and repairs to be carried out.

Best Practices for Lifting in Mechanical Workshops:

- Proper Training: It is crucial that all workers are trained in the proper use of lifting equipment and safety procedures.

- Regular Maintenance: Lifting tools must be inspected and maintained regularly to ensure their safe and reliable operation.

- Load assessment: It is important to assess the weight and size of the load before attempting to lift it, to avoid overloading and malfunctioning.

Adopting these practices reduces the risk of accidents and improves operational efficiency, contributing to a safer and more productive working environment.

To ensure safe lifting, it is essential:

- Use Certified Equipment: Tools and equipment must be certified and comply with current safety standards.

- Check the stability of the load: Ensure that the load is well balanced and secured before lifting.

- Adopt Safety Practices: Wear appropriate protective clothing and follow safety procedures to minimise the risk of injury.

Investing in high quality equipment is essential to ensure safety and efficiency. Equipment includes:

- Hoists and Lifting Straps: Essential for safely securing and transporting cargo.

- Lifting Bridges: Used to lift vehicles and other heavy structures in a stable and safe manner.

- Hydraulic Lifts: Offer a powerful and versatile solution for lifting heavy loads.

Answers to Frequently Asked Questions

How can I ensure that lifting equipment is safe?

Make sure you buy certified equipment and perform regular inspections and maintenance. Follow the manufacturer's guidelines and provide adequate training to your workers.

What is the importance of training in lifting?

Training is crucial to ensure that workers know how to use lifting equipment correctly and follow safety procedures, reducing the risk of accidents and improving operational efficiency.

In conclusion, lifting is a fundamental aspect of machine shop operations, directly influencing work safety and efficiency. Implementing the correct lifting techniques, using the right tools and following best practices can transform day-to-day operations, improving productivity and ensuring a safe working environment. Investing in high-quality training and equipment is essential to maximise the benefits of lifting and maintain high standards of safety and operation.

-

Electric chain hoists13 products

-

Lift trucks5 products

-

Jib cranes19 products

-

Modular system monorails and travelling cranes0 products

-

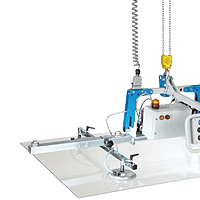

Vacuum tube lifters5 products

-

Pneumatic chain hoists1 products

-

Pneumatic balancers0 products

-

Industrial manipulators0 products

-

Manual chain hoists2 products

-

Lifting accessories54 products

-

Magnetic lifters6 products

-

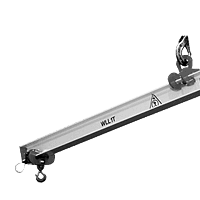

Lifting monobeams6 products

-

Transpallets8 products

-

Cranes and hydraulic lifters33 products