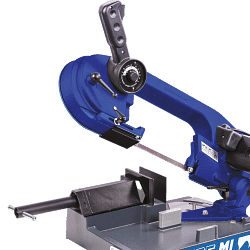

Band saws are an essential tool in modern machine shops. These machines, known for their precision and versatility, are designed to perform clean and accurate cuts on a wide range of materials, from the hardest metals to the most delicate woods. Their importance in the industrial sector is undeniable, as they optimise production processes, reducing machining times and improving the quality of the end product.

Understanding band saws

Band saws are machine tools that use a continuous blade, called a band, to make cuts in various materials. The blade is mounted on two wheels, one driving and one driven, which make it move continuously. This movement allows precise and uniform cuts to be obtained, minimising processing waste. Band saws are available in different configurations, including vertical and horizontal models, each designed for specific industrial applications.

Band saw applications in machine shops

In machine shops, band saws are used for a wide range of operations. They are ideal for cutting metals, alloys, plastics and wood, making them versatile and indispensable tools. Due to their ability to perform complex and precise cuts, they are often used in the production of mechanical components, the machining of metal profiles and the production of prototypes. The possibility of adjusting the band speed and cutting angle allows the machine to be adapted to the specific requirements of the material to be processed.

Advantages of band saws

The use of band saws offers numerous advantages. First of all, the precision of the cut is one of the main strengths of these machines. The band saw blade, thanks to its continuity and the fact that it can be sharpened precisely, guarantees clean, burr-free cuts. Furthermore, band saws are known for their energy efficiency, as they require less power than other types of sawing machines. This translates into operating cost savings and a lower environmental impact.

Another significant advantage is operational safety. Band saw machines are designed with advanced safety systems that protect the operator during use. These include blade guards, emergency switches and automatic locking systems. In addition, maintenance of band saws is relatively simple, thanks to easy access to key components and the availability of spare parts.

Optimal utilisation of band saws

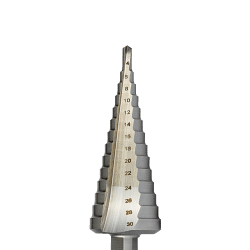

To get the most out of band saws, it is essential to follow certain operational guidelines. First of all, it is important to choose the right blade for the material to be cut. Blades are available in different sizes and materials, each designed for specific applications. For example, carbon steel blades are ideal for cutting wood and plastic, while alloy steel blades are more suitable for metals.

The correct blade tension is another crucial aspect. A blade that is too tight can easily break, while a blade that is too loose can cause inaccurate cuts. It is therefore essential to adjust the tension according to the manufacturer's specifications. In addition, the belt speed must be adapted to the material and the type of cut desired. Too high a speed can overheat the blade and damage the material, while too low a speed can slow down the cutting process.

Frequently asked questions about band saws

Many operators ask questions about the use and maintenance of band saws. One of the most common questions concerns the service life of the blade. The service life of a blade depends on several factors, including the type of material cut, frequency of use and maintenance. In general, a well-maintained blade can last several weeks or months, depending on the intensity of the work.

Another frequently asked question concerns the choice between vertical and horizontal band saws. The choice depends mainly on the specific application. Vertical saws are ideal for complex and detailed cuts, while horizontal saws are more suitable for straight and large cuts.

Finally, many people wonder how to improve cutting precision. In addition to choosing the right blade and correctly adjusting tension and speed, it is important to keep the machine clean and well lubricated. Regular chip removal and lubrication of moving parts help keep the machine in optimal condition, ensuring accurate and uniform cuts.

Conclusions

Band saws are indispensable tools in machine shops due to their precision, versatility and efficiency. Understanding their operation and best working practices allows them to be used to their full potential, improving the quality of work and optimising production processes. With proper maintenance and use, band saws can be a lasting and profitable investment for any machine shop.

Read More Read Less