Touch probes

Probes, also known as gauging probes or probes, are essential tools in modern machine shops to ensure precision and efficiency in the machining of parts. Used predominantly in CNC (computer numerical control) machine tools, probes allow accurate measurements to be taken directly during the machining process, reducing downtime and scrap.

Advantages of Touch Probes

- Accuracy

One of the main advantages of touch probes is their ability to accurately detect the position and dimensions of machined parts. This is particularly useful in milling, turning and grinding operations, where dimensional tolerance is crucial.

- Reducing Setup Times

Touch probes automate many measuring operations that would otherwise require manual time and attention. This means that machine setup can be carried out more quickly, increasing overall productivity.

- Less scrap

Thanks to their accuracy, touch probes reduce the possibility of errors, thus minimising scrap. This not only improves efficiency, but also contributes to greater environmental sustainability.

- Continuous Monitoring

Touch probes allow continuous monitoring during the machining process, detecting any deviations from design specifications and allowing real-time corrections.

There are various types of probes, including touch probes, non-contact probes and laser probes. Each type has specific applications and advantages:

- Contact Probes: Used for high-precision measurements, they are ideal for complex surfaces.

- Non-Contact Probes: Perfect for sensitive materials that cannot be touched, such as electronic components.

- Laser Probes: Offer fast and accurate measurement without physical contact, ideal for delicate and complex surfaces.

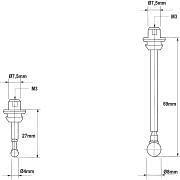

The probes are made of high-quality materials such as stainless steel and tungsten carbide, ensuring durability and wear resistance. The tips are often interchangeable, allowing the touch probe to be adapted to different applications:

- Integration with CNC

Most modern probes are designed to be easily integrated with CNC systems, offering advanced features such as auto-calibration and automatic error compensation.

- Probe applications

Milling: In milling, touch probes are used to position the workpiece correctly and to check dimensions during and after machining.

Turning: In turning, touch probes ensure that each workpiece is centred correctly and that dimensions conform to specifications.

Grinding: During grinding, touch probes continuously monitor the process to ensure a high quality finish and to maintain dimensional tolerances.

Touch probes are therefore indispensable tools in modern machine shops, offering precision, efficiency and reduced operating costs. Their ability to integrate with CNC machines and their diverse applications make them versatile and highly effective for a wide range of machining processes.

-

Promo

D2290

Lever test indicators ALPA MEGATASTfrom €151.00 to €225.00

Special Price -26%

from €112.00 to €168.00 -

Promo

-

Promo

-

-

-

-

-

-

-