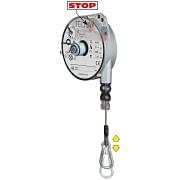

Balancers

At the beating heart of mechanical workshops, where precision and efficiency are paramount, balancers play a crucial role. These sophisticated, often underestimated tools are essential to ensure that mechanical operations run smoothly. But what exactly are balancers? What are they used for and what advantages do they offer?

Balancers are devices used to reduce the effort required to handle heavy or bulky tools. In practice, they allow operators to work more easily, balancing the weight of tools and reducing fatigue. They are often used in production environments and machine shops, where heavy tools are the order of the day.

The operation of balancers is based on a system of springs or counterweights that neutralise the weight of the attached instruments. This system keeps the tools in a stable position and reduces the physical effort required to lift and handle them. Balancers for machine shops are designed to be robust and reliable, ensuring a long service life even in demanding working environments.

The use of balancers in mechanical engineering is varied and widespread. They are used to support drills, screwdrivers, welders and other heavy tools, allowing operators to work more efficiently and safely. With balancers, tools can be easily positioned and kept in balance, reducing the risk of accidents and improving the accuracy of the work performed.

Advantages of Mechanical Balancers

- Reducing Fatigue

One of the main advantages of balancers is the significant reduction in operator fatigue. Lifting and handling heavy tools for long periods can be physically exhausting. Balancers alleviate this strain, allowing workers to concentrate on the task at hand without muscle fatigue.

- Improving Safety

Safety at work is a priority in any machine shop. Balancers help create a safer working environment by reducing the risk of injury caused by repetitive movements and heavy lifting. With correctly balanced tools, operators can work more safely and efficiently.

- Increased Productivity

With balancers, operators can work faster and more accurately. Reduced fatigue and increased safety lead to an overall improvement in productivity. Tools are always at hand and ready to use, reducing downtime and improving operational efficiency.

- Durability of Tools

Another advantage of balancers is the protection of instruments. By reducing stress and wear on tools, balancers help to extend their service life. This not only reduces tool replacement costs, but also ensures that tools are always in optimal condition for use.

- Versatility

Balancers are extremely versatile and can be used with a wide range of tools. This makes them a valuable investment for any machine shop, as they can be adapted to different operational requirements. The possibility of adjusting the tension of the balancers makes them suitable for tools of different sizes and weights.

Frequently Asked Questions about balancers

What are the main types of balancers available?

There are several types of balancers, including spring balancers, counterbalance balancers and pneumatic balancers. Each type has its own characteristics and advantages, and the choice depends on the specific operational needs of the workshop.

How do I choose the right balancer for my workshop?

Choosing the right balancer depends on the weight of the tools used and the specific operations performed in the workshop. It is important to consider the load capacity, cable length and robustness of the balancer to ensure that it meets operational requirements.

Do balancers require maintenance?

Yes, balancers require regular maintenance to ensure optimal operation. It is advisable to periodically check the spring or counterweight mechanism and lubricate moving parts to prevent wear and tear and prolong the life of the device.

Balancers are indispensable tools for machine shops, offering numerous advantages in terms of safety, efficiency and durability. Investing in quality balancers can make a difference in day-to-day operations, improving the well-being of workers and increasing overall productivity. If you are looking for a way to optimise your mechanical operations, balancers are a practical and effective solution.

-

-

-

Promo

L2200

Spring balancers light series run 1600 TECNAfrom €39.04 to €46.56

Special Price -26%

from €29.00 to €35.00 -

-

-

-

-

-