Milling cutters

In the world of machine shops, milling tools are a key component in ensuring precision, efficiency and quality in work. These tools are used to remove material from a blank to obtain the desired shape, through a controlled removal process. The correct choice and use of milling tools can make the difference between a job well done and a mediocre one.

CNC milling tools are designed for CNC machines, offering unparalleled precision and repeatability. These tools are made from high-quality materials, such as tungsten carbide, which guarantees wear resistance and durability. Using CNC milling tools allows you to work to very tight tolerances and achieve excellent surface finishes, minimising scrap and production time.

The choice of the best milling tools depends on various factors, including the material to be machined, the type of machine and the project specifications. Among the most popular are carbide tools, which are ideal for precision machining of hard metals. Tools coated with TiN (titanium nitride) or TiAlN (titanium-aluminium nitride) are also widely used for their ability to reduce friction and improve tool life.

Metal milling requires specific tools that can withstand high temperatures and mechanical stresses. Metal milling tools are designed to ensure uniform material removal while minimising vibration and deformation of the workpiece. Using appropriate tools is crucial to avoid problems such as premature tool wear or poor machined surface quality.

In woodworking, milling tools also play a key role. These tools must be sharp and precise to ensure clean, clean cuts. Wood milling tools are often made of high speed steel (HSS) or with carbide inserts, offering a good combination of durability and ease of sharpening. Choosing the right tool can significantly affect the quality of work and productivity.

Maintenance of milling tools is essential to ensure their long life and operational efficiency. Regularly cleaning tools, inspecting for damage and sharpening blades are fundamental practices. A well-maintained tool not only improves the quality of work, but can also reduce operating costs by avoiding the need for frequent tool replacement.

Frequently Asked Questions

What are the main types of milling tools?

Milling tools can vary in shape, such as cylindrical milling cutters, conical milling cutters and disc milling cutters. Each of these types is designed for specific applications and offers different advantages.

How to choose the right tool for a given application?

The choice of tool depends on the material to be machined, the type of machining required and the machine specifications. Consulting manufacturers' catalogues and seeking advice from industry experts can help you make the right choice.

In conclusion, milling tools are indispensable in machine shops for precise and high-quality machining. Choosing the right tools, keeping them in good condition and using them correctly can significantly improve productivity and work quality while reducing operating costs.

-

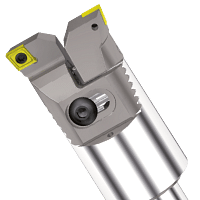

End milling cutters and inserts4 products

-

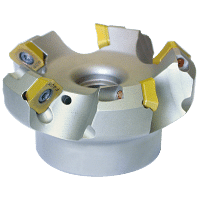

Shoulder milling cutters and inserts26 products

-

High feed milling cutters and inserts14 products

-

Multifunctional milling cutters and round inserts10 products

-

Groove milling cutters and inserts8 products

-

Milling cutters and inserts for counterbores and smoothing20 products

-

Modular boring system26 products