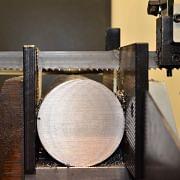

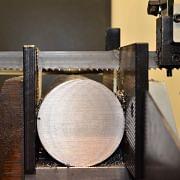

Band saw blades

Band saw blades are an essential tool in machine shops, ensuring precise and efficient cuts on a wide range of materials. Whether cutting metal, wood or plastic, band saw blades are designed to meet the most specific requirements and ensure maximum productivity.

Band saw blades offer high cutting precision. This feature is essential for machine shops that work with high-quality materials and require a flawless finish. Band saw blades guarantee clean edges and clean cuts, minimising the need for further machining.

In addition, the versatility of band saw blades is another big advantage. These blades can be used to cut a variety of materials, from metal to wood, from plastic to composites. This flexibility allows machine shops to tackle a wide range of projects with a single tool, thereby optimising production time and costs.

Another aspect to consider is the durability of band saw blades. Thanks to the high quality materials they are made of, such as hardened steel and tungsten carbide, these blades offer long life and superior wear resistance. This means fewer interruptions for blade replacement and greater operational continuity.

There are different variants of band saw blades, each designed for specific applications. These include bimetal blades, which are ideal for cutting hard metals due to their strength and flexibility. Carbide blades, on the other hand, are perfect for abrasive and difficult-to-cut materials. For wood, fine-tooth blades offer a precise, splinter-free cut, while coarse-tooth blades allow fast and efficient cuts on thick materials.

The choice of band saw blade depends on several factors, including the type of material to be cut, the thickness of the material and the desired cutting speed. The size and pitch of the teeth of the blade is also important to consider. For example, a blade with small teeth is ideal for fine and detailed cuts, while a blade with large teeth is more suitable for quick and coarse cuts.

Band saw blades are an indispensable investment for any machine shop that wants to improve the precision and efficiency of its cutting processes. By choosing the right blade, you can optimise operations, reduce costs and ensure the highest quality of finished products.