Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

02.927371

- Supporting big orders

02.38298620

-

info@linkindustrialtools.it

- Request assistance with form

Or contact us with the chat in the lower right corner

< Milling cutters

- Home

- Milling cutters

- End milling cutters and inserts

End milling cutters and inserts

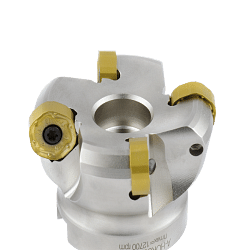

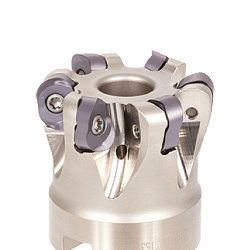

In the world of machine shops, precision and efficiency are key elements in guaranteeing the quality of the end product. Among the most essential tools for achieving these goals, milling cutters and face milling inserts occupy a prominent place. These tools, when used correctly, can significantly improve the productivity and quality of machining operations. In this in-depth look, we will explore in detail what face milling cutters and inserts are, how they are used, the advantages they offer, and answer some of the most frequently asked questions about these tools.

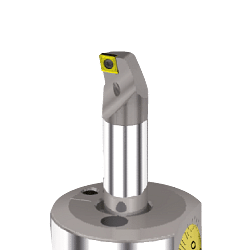

Understanding face milling cutters and inserts

Face milling cutters are cutting tools mainly used for machining flat surfaces on metal parts. These tools are designed to remove excess material and create a smooth, even surface. Face milling inserts, on the other hand, are interchangeable components that fit on cutters to improve their efficiency and durability. The inserts are made of wear-resistant materials, such as tungsten carbide, and are designed to withstand the high temperatures and pressures generated during machining.

The importance of face milling cutters and inserts in machine shops

In machine shops, the use of face milling cutters and inserts is crucial to ensure that the surfaces of machined parts are perfectly flat and free of imperfections. This is especially important in industries such as automotive and aerospace, where precision is essential for the proper functioning of components. Face milling cutters allow high quality surfaces to be obtained in a short time, thus improving the overall efficiency of the production process.

How to use face milling cutters and inserts correctly

The correct use of face milling cutters and inserts requires a thorough understanding of their characteristics and operating conditions. It is essential to select the right cutter and insert according to the material to be machined and the project specifications. In addition, it is important to correctly adjust cutting parameters, such as feed speed and depth of cut, to optimise performance and prolong tool life.

Advantages of using face milling cutters and inserts

The adoption of face milling cutters and inserts offers several advantages to machine shops. Firstly, these tools allow high quality surfaces with an excellent finish to be obtained, reducing the need for subsequent machining. Furthermore, the use of interchangeable inserts reduces machine downtime, as inserts can be quickly replaced without having to remove the entire cutter. This results in increased productivity and reduced operating costs.

Frequently asked questions about face milling cutters and inserts

1. What are the most common materials used for face milling inserts?

Face milling inserts are generally made of tungsten carbide, ceramic or cermet. These materials offer excellent resistance to wear and high temperatures, making them ideal for face milling applications.

2. How can I extend the service life of face milling cutters and inserts?

To prolong the service life of cutters and inserts, it is important to follow the manufacturer's recommendations regarding cutting parameters and maintenance. In addition, the use of appropriate lubricants can reduce wear and improve tool performance.

3. What are the signs that a face milling insert needs to be replaced?

Signs that an insert needs to be replaced include a reduction in surface finish quality, increased vibration during machining and an increase in the cutting force required.

4. Can milling cutters and inserts be used for face milling on materials other than metal?

Yes, face milling cutters and inserts can be used on a variety of materials, including plastic and wood, as long as the appropriate tools and cutting parameters are selected for the specific material.

5. What are the current trends in the design of face milling cutters and inserts?

Current trends in the design of face milling cutters and inserts include the development of advanced geometries to improve cutting efficiency and the use of innovative coatings to increase wear resistance.

In conclusion, face milling cutters and inserts are indispensable tools in modern machine shops. Their ability to improve the quality of machined surfaces and increase production efficiency makes them an ideal choice for a wide range of industrial applications. With proper selection and maintenance, these tools can offer exceptional performance and contribute to the success of machining operations.

Read More Read LessUnderstanding face milling cutters and inserts

Face milling cutters are cutting tools mainly used for machining flat surfaces on metal parts. These tools are designed to remove excess material and create a smooth, even surface. Face milling inserts, on the other hand, are interchangeable components that fit on cutters to improve their efficiency and durability. The inserts are made of wear-resistant materials, such as tungsten carbide, and are designed to withstand the high temperatures and pressures generated during machining.

The importance of face milling cutters and inserts in machine shops

In machine shops, the use of face milling cutters and inserts is crucial to ensure that the surfaces of machined parts are perfectly flat and free of imperfections. This is especially important in industries such as automotive and aerospace, where precision is essential for the proper functioning of components. Face milling cutters allow high quality surfaces to be obtained in a short time, thus improving the overall efficiency of the production process.

How to use face milling cutters and inserts correctly

The correct use of face milling cutters and inserts requires a thorough understanding of their characteristics and operating conditions. It is essential to select the right cutter and insert according to the material to be machined and the project specifications. In addition, it is important to correctly adjust cutting parameters, such as feed speed and depth of cut, to optimise performance and prolong tool life.

Advantages of using face milling cutters and inserts

The adoption of face milling cutters and inserts offers several advantages to machine shops. Firstly, these tools allow high quality surfaces with an excellent finish to be obtained, reducing the need for subsequent machining. Furthermore, the use of interchangeable inserts reduces machine downtime, as inserts can be quickly replaced without having to remove the entire cutter. This results in increased productivity and reduced operating costs.

Frequently asked questions about face milling cutters and inserts

1. What are the most common materials used for face milling inserts?

Face milling inserts are generally made of tungsten carbide, ceramic or cermet. These materials offer excellent resistance to wear and high temperatures, making them ideal for face milling applications.

2. How can I extend the service life of face milling cutters and inserts?

To prolong the service life of cutters and inserts, it is important to follow the manufacturer's recommendations regarding cutting parameters and maintenance. In addition, the use of appropriate lubricants can reduce wear and improve tool performance.

3. What are the signs that a face milling insert needs to be replaced?

Signs that an insert needs to be replaced include a reduction in surface finish quality, increased vibration during machining and an increase in the cutting force required.

4. Can milling cutters and inserts be used for face milling on materials other than metal?

Yes, face milling cutters and inserts can be used on a variety of materials, including plastic and wood, as long as the appropriate tools and cutting parameters are selected for the specific material.

5. What are the current trends in the design of face milling cutters and inserts?

Current trends in the design of face milling cutters and inserts include the development of advanced geometries to improve cutting efficiency and the use of innovative coatings to increase wear resistance.

In conclusion, face milling cutters and inserts are indispensable tools in modern machine shops. Their ability to improve the quality of machined surfaces and increase production efficiency makes them an ideal choice for a wide range of industrial applications. With proper selection and maintenance, these tools can offer exceptional performance and contribute to the success of machining operations.