Pneumatics

In the world of mechanical workshops, pneumatics play a key role. Used in a wide range of applications, from automation systems to precision controls, pneumatics is essential for improving work efficiency and safety.

Pneumatics is a branch of technology that uses compressed gases to generate mechanical motion. In industry and machine shops, pneumatic systems are often preferred for their reliability, versatility and safety. The main components of a pneumatic system include compressors, valves, cylinders and actuators.

Pneumatics are used in many operations in machine shops. Pneumatic systems for machine shops find application in various tasks, such as lifting heavy loads, controlling pneumatic tools, and automating repetitive processes. For example, pneumatic spanners are essential for tightening and loosening bolts quickly, while pneumatic lifters facilitate car maintenance.

The use of pneumatic systems has many advantages:

- Energy Efficiency: Pneumatic systems are highly efficient, as compressed air can be generated and used on-demand, reducing energy waste.

- Reliability: Due to their simple construction and the absence of complex electrical components, pneumatic systems are less prone to failure.

- Safety: Pneumatic systems operate at low pressures and do not produce sparks, making them ideal for environments where safety is a priority.

- Flexibility: Pneumatics can be easily integrated with other systems and adapted to different operational needs.

The applications of pneumatics in the mechanical engineering industry are many and varied. From automated production to robotics, pneumatics offers innovative solutions to improve production efficiency. In particular, in the automotive and aerospace sectors, pneumatic systems are used for precision operations and assembly.

Frequently Asked Questions about Pneumatics

What are the main advantages of pneumatic systems?

The main advantages include energy efficiency, reliability, safety and flexibility of use.

How is a pneumatic system maintained?

Maintenance includes checking pressure, checking valves, replacing filters and inspecting hoses for leaks.

What are the common applications of pneumatics in machine shops?

Common applications include the use of pneumatic spanners, pneumatic lifters and automation systems for repetitive processes.

In conclusion, pneumatics is an indispensable resource for machine shops due to its many advantages and versatility. Investing in quality pneumatic systems and maintaining them ensures an efficient and safe working environment, improving productivity overall.

-

Air impact wrenches26 products

-

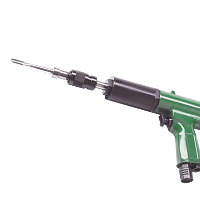

Pneumatic tapping units5 products

-

Drills7 products

-

Engraving pens2 products

-

Pneumatic grinders24 products

-

Filing and lapping machines6 products

-

Balancers9 products

-

Blow guns and inflators34 products

-

Airbrushes3 products

-

Pressure regulators11 products

-

Pipes and fittings98 products

-

Compressors5 products