Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

02.927371

- Supporting big orders

02.38298620

-

info@linkindustrialtools.it

- Request assistance with form

Or contact us with the chat in the lower right corner

< Workshop equipment

- Home

- Workshop equipment

- Control knobs

Control knobs

In the world of machine shops, precision and efficiency are key elements in ensuring quality work and customer satisfaction. Among the tools that help achieve these goals, handwheels, knobs and cranks play a crucial role. These often underestimated components are essential for the control and adjustment of machinery and equipment, providing an intuitive and reliable interface between the operator and the machine.

The importance of handwheels, knobs and cranks

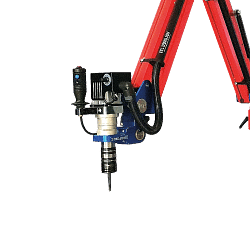

Handwheels, knobs and crank handles are mechanical devices designed to facilitate manual control of machinery and equipment. These tools are used in a wide range of industrial applications, from machine tools to laboratory equipment, and are essential to ensure safe and efficient operation.

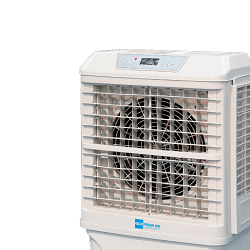

Handwheels are generally used to adjust the position or speed of a moving component, such as an axis or spindle. Knobs, on the other hand, are often used to control parameters such as pressure or temperature, while cranks are used to transmit rotary motion to a mechanism.

Materials and design: key factors for choice

The choice of materials and design is key to ensuring the durability and reliability of handwheels, knobs and cranks. Common materials include metals such as stainless steel and aluminium, known for their resistance to corrosion and deformation. However, in some applications, advanced plastics can be used, which offer light weight and chemical resistance.

Ergonomic design is another crucial aspect, as it directly affects ease of use and operator comfort. A well-designed design reduces fatigue and increases control accuracy, thus improving the overall efficiency of the production process.

Practical applications in machine shops

In machine shops, handwheels, knobs and crank handles find application in numerous contexts. For example, in lathes and milling machines, handwheels are used to precisely adjust the position of tools, enabling accurate and repeatable machining. Handwheels, on the other hand, can be used to control the pressure of cooling fluids, ensuring adequate heat dissipation during cutting operations.

Finally, cranks are often used in lifting and handling systems, where it is necessary to apply a rotating force to move heavy loads. In these contexts, the strength and reliability of crank handles are essential to ensure the safety of operators and the protection of equipment.

Advantages of using handwheels, knobs and cranks

The use of handwheels, knobs and cranks offers numerous benefits, including increased control and precision in operations, reduced operator fatigue and improved overall safety. These tools allow operators to make fine adjustments and respond quickly to changes in operating conditions, thereby increasing efficiency and productivity.

Furthermore, the ability to customise these components to the specific needs of the application allows for optimised system performance and reduced downtime. Regular maintenance and inspection of these components is essential to ensure continuous and reliable operation.

Frequently asked questions on the use of handwheels, knobs and cranks

One of the most common questions concerns the choice of the most suitable material for a specific application. The answer depends on various factors, including the operating environment, mechanical stresses and chemical resistance requirements. In general, metals are preferred for high-strength applications, while plastic materials can be used in corrosive environments or where lightness is required.

Another frequent question concerns the maintenance of these components. It is important to carry out regular checks for signs of wear or damage, and to replace defective components to avoid sudden failures. Regular lubrication is essential to ensure smooth operation and reduce friction.

Conclusion: the importance of an informed choice

In conclusion, handwheels, knobs and crank handles are essential components for controlling and adjusting machinery in machine shops. Choosing the right material and design, together with proper maintenance, can make all the difference in terms of equipment efficiency, safety and durability. Investing in high quality components customised to your operational needs is a winning strategy to improve performance and competitiveness in the industry.

Read More Read LessThe importance of handwheels, knobs and cranks

Handwheels, knobs and crank handles are mechanical devices designed to facilitate manual control of machinery and equipment. These tools are used in a wide range of industrial applications, from machine tools to laboratory equipment, and are essential to ensure safe and efficient operation.

Handwheels are generally used to adjust the position or speed of a moving component, such as an axis or spindle. Knobs, on the other hand, are often used to control parameters such as pressure or temperature, while cranks are used to transmit rotary motion to a mechanism.

Materials and design: key factors for choice

The choice of materials and design is key to ensuring the durability and reliability of handwheels, knobs and cranks. Common materials include metals such as stainless steel and aluminium, known for their resistance to corrosion and deformation. However, in some applications, advanced plastics can be used, which offer light weight and chemical resistance.

Ergonomic design is another crucial aspect, as it directly affects ease of use and operator comfort. A well-designed design reduces fatigue and increases control accuracy, thus improving the overall efficiency of the production process.

Practical applications in machine shops

In machine shops, handwheels, knobs and crank handles find application in numerous contexts. For example, in lathes and milling machines, handwheels are used to precisely adjust the position of tools, enabling accurate and repeatable machining. Handwheels, on the other hand, can be used to control the pressure of cooling fluids, ensuring adequate heat dissipation during cutting operations.

Finally, cranks are often used in lifting and handling systems, where it is necessary to apply a rotating force to move heavy loads. In these contexts, the strength and reliability of crank handles are essential to ensure the safety of operators and the protection of equipment.

Advantages of using handwheels, knobs and cranks

The use of handwheels, knobs and cranks offers numerous benefits, including increased control and precision in operations, reduced operator fatigue and improved overall safety. These tools allow operators to make fine adjustments and respond quickly to changes in operating conditions, thereby increasing efficiency and productivity.

Furthermore, the ability to customise these components to the specific needs of the application allows for optimised system performance and reduced downtime. Regular maintenance and inspection of these components is essential to ensure continuous and reliable operation.

Frequently asked questions on the use of handwheels, knobs and cranks

One of the most common questions concerns the choice of the most suitable material for a specific application. The answer depends on various factors, including the operating environment, mechanical stresses and chemical resistance requirements. In general, metals are preferred for high-strength applications, while plastic materials can be used in corrosive environments or where lightness is required.

Another frequent question concerns the maintenance of these components. It is important to carry out regular checks for signs of wear or damage, and to replace defective components to avoid sudden failures. Regular lubrication is essential to ensure smooth operation and reduce friction.

Conclusion: the importance of an informed choice

In conclusion, handwheels, knobs and crank handles are essential components for controlling and adjusting machinery in machine shops. Choosing the right material and design, together with proper maintenance, can make all the difference in terms of equipment efficiency, safety and durability. Investing in high quality components customised to your operational needs is a winning strategy to improve performance and competitiveness in the industry.