< Workshop equipment Threaded inserts

Thread inserts are an essential component in the machine shop sector, offering advanced solutions for the restoration and maintenance of damaged threads. These elements, also known as thread inserts, are designed to improve the strength and durability of threads in various materials, including metals and light alloys. In this in-depth look, we will explore in detail what thread inserts are, their use, the benefits they offer and answer frequently asked questions on this topic.

Understanding thread inserts

Thread inserts are cylindrical inserts that are inserted into an existing hole to restore or improve a thread. They are commonly used in applications where the original thread has been damaged or where increased strength is required. These inserts are available in various materials, including stainless steel, bronze and plastic, and can be used in a wide range of industrial applications.

Applications and use of thread inserts

Machine shops use thread inserts in a variety of contexts. They are particularly useful in situations where the original threads have been compromised due to wear, corrosion or mechanical damage. The installation of a thread locker allows the thread to be restored without the need to replace the entire component. In addition, thread inserts can be used to improve the strength of threads in weaker materials, such as aluminium or magnesium, that may not be able to withstand high loads.

Advantages of thread inserts

The use of thread inserts offers several advantages. Firstly, they extend the service life of components, reducing the need for costly replacements. They also improve the strength of threads, making them more resistant to high loads and adverse environmental conditions. Thread inserts are also easy to install, making them a practical and cost-effective solution for machine shops. Finally, the use of thread inserts can help reduce machine downtime, improving overall operating efficiency.

Materials and types of thread inserts

There are different types of thread inserts, each designed for specific applications and materials. Stainless steel inserts are ideal for applications requiring high corrosion resistance, while bronze inserts are preferred for applications requiring good thermal and electrical conductivity. Plastic inserts, on the other hand, are used in applications where weight is a critical factor. Choosing the right material is critical to ensuring optimum performance of the thread insert.

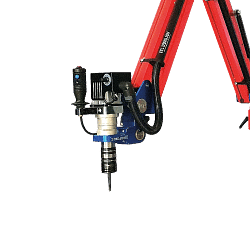

Installation of thread inserts

The installation of thread inserts requires precision and attention to detail. The process begins with the preparation of the hole, which must be clean and free of debris. Next, a specific tool is used to insert the thread lead into the hole. It is important to follow the manufacturer's instructions to ensure proper and safe installation. Once installed, the thread flare offers a robust and reliable thread, ready for immediate use.

Frequently asked questions about thread inserts

1. What are the standard dimensions of thread inserts?

The dimensions of thread inserts vary depending on the application and manufacturer. It is important to consult the technical specifications to determine the correct size for your application.

2. Can thread inserts be removed and reused?

In general, thread inserts are not designed to be removed and reused. However, in some cases, they can be removed using specific tools, but this may compromise the integrity of the thread.

3. What is the lifespan of a reported thread?

The lifetime of a thread insert depends on various factors, including the insert material, operating conditions and correct installation. In optimal conditions, thread inserts can last for many years.

4. Is it possible to use thread inserts in high temperature applications?

Yes, there are thread inserts designed to withstand high temperatures. It is important to choose the appropriate material to ensure the desired performance in high temperature environments.

5. How do I choose the right thread lead for a specific application?

Choosing the right thread lead depends on several factors, including the component material, operating conditions and load requirements. It is advisable to consult an expert or the manufacturer for specific advice.

Conclusion

Thread inserts are a versatile and reliable solution for restoring and improving threads in machine shops. They offer numerous advantages, including increased strength, extended service life and easy installation. Understanding the different types and materials available is key to choosing the right thread whip for each application. With the right attention to detail and proper installation, thread inserts can contribute significantly to the efficiency and longevity of mechanical operations.

Read More Read Less