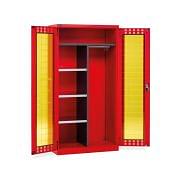

Security cabinets

In the world of machine shops, safety and organisation are key elements in ensuring an efficient and risk-free working environment. Safety cabinets are essential devices that provide safe storage solutions for hazardous materials, equipment and chemicals.

Safety cabinets are specially designed containers for the safe storage of hazardous materials and substances. Made of durable materials and equipped with advanced locking systems, these cabinets ensure that the contents are protected from unauthorised access, fire and accidental spillage.

Safety cabinets for machine shops are mainly used for:

- Storing chemicals and flammable materials.

- Protect expensive and delicate equipment.

- Organise the work space efficiently.

- Prevent accidents related to the handling of hazardous materials.

The use of safety cabinets in machine shops is simple but requires attention to specific details:

- Identification of Materials: It is essential to know which materials must be stored safely.

- Proper Placement: Cabinets should be placed in areas that are easily accessible but away from sources of heat or flame.

- Secure Locking: Ensure that doors are always locked when not in use.

- Labelling: Clearly label the outside of the cabinet with information about the materials stored inside.

The adoption of safety cabinets in machine shops brings many benefits, including:

- Improved Safety: Reduced risk of fires, explosions and hazardous substance spills.

- Asset Protection: Fireproof cabinets protect expensive equipment from fire damage.

- Optimal Organisation: The ability to better organise work space, making it easier to find and access necessary materials.

- Regulatory Compliance: Safety cabinets help comply with current occupational safety regulations.

Frequently Asked Questions about Safety Storage Cabinets

What are the regulations for safety cabinets in machine shops?

Regulations vary depending on the country and the type of substances stored, but generally include requirements for fire resistance, locking systems and adequate ventilation.

How do I choose the right safety cabinet for my workshop?

The choice depends on the type and quantity of materials to be stored. It is also important to consider fire resistance and the presence of specific certifications.

Do safety storage cabinets require maintenance?

Yes, it is advisable to carry out periodic checks to ensure that the locks are working properly and that there is no structural damage.

In conclusion, safety cabinets are indispensable tools for any machine shop that wants to improve safety and operational efficiency. Investing in high-quality cabinets is a wise choice that ensures the protection of hazardous materials and equipment, contributing to a safe and organised working environment.