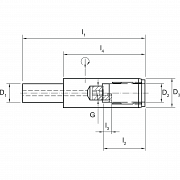

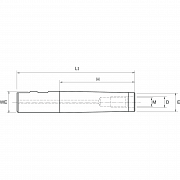

Chucks DIN 2080 and cylindrical

DIN 2080 and cylindrical spindles are essential components in machine shops due to their precision and reliability. These tools are designed to ensure safe and stable clamping of tools, thus improving the quality and efficiency of machining operations.

DIN 2080 spindles are particularly appreciated for their compatibility with standardised machine tools, following DIN 2080 specifications, an international standard that guarantees uniformity and interchangeability. These spindles are used in a variety of milling, drilling and turning applications. Their robust construction and precision clamping surfaces ensure firm and stable clamping, minimising vibration and improving the finish of machined parts.

Cylindrical chucks, on the other hand, are known for their versatility and ease of use. They are characterised by their compact design, which allows easy assembly and disassembly of tools, making tool change operations quick. This feature is particularly advantageous in operations that require frequent tool changes, significantly improving workshop productivity.

Both spindle types offer a number of advantages. These include the ability to maintain high levels of accuracy and repeatability, which are essential for mass production and work requiring tight tolerances. The DIN 2080 and cylindrical spindles are made of high-quality materials, such as hardened steel, which guarantees long life and wear resistance. In addition, their design takes into account ease of maintenance, allowing operators to keep the spindles in optimum condition with minimal intervention.

Another relevant aspect is their ability to reduce setup times, a crucial factor in improving operational efficiency. The speed and safety with which DIN 2080 and cylindrical spindles can be assembled and disassembled on machine tool spindles means that downtime can be reduced and effective machining time increased. This translates into higher productivity and better utilisation of resources.

The adoption of DIN 2080 and cylindrical spindles in machine shops is a strategic choice to improve the precision, productivity and reliability of machining operations. Thanks to their advanced design and high-quality materials, these tools offer superior performance and high durability, meeting the demands of modern machining operations. Investing in DIN 2080 and cylindrical spindles means ensuring a successful future for workshops, improving the quality of finished products and optimising production processes.

-

-

-

-

-

-

-

-

-

C3180

Threaded coupling carbide chucks with cylindrical and reduced taper TUKOYfrom €365.00 to €735.00 -