HSS drills: an in-depth analysis for machine shops

In the world of machine shops, the choice of the right tools is crucial to ensure precision, efficiency and durability. Among the most commonly used tools, HSS (High-Speed Steel) drills occupy a prominent place due to their unique characteristics and versatility. In this article, we will explore in detail what HSS drills are, what they are used for, how they are used and what advantages they offer over other types of drills.

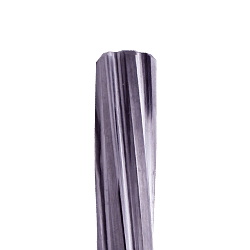

What are HSS drills?

HSS drills, which stands for High-Speed Steel, are cutting tools made of super-speed steel. This material is known for its ability to retain its hardness even at high temperatures, making it ideal for high-speed applications. HSS drills are designed to drill a wide range of materials, including metals, alloys, plastics and wood, offering a versatile solution to the needs of machine shops.

What are HSS drills used for?

HSS drills are mainly used for drilling metal materials, but their versatility makes them suitable for other materials as well. Due to their resistance to heat and wear, they are particularly effective in applications requiring high cutting speeds. HSS drills are commonly used in industries such as automotive, aerospace, machine building and handicraft, where precision and hole quality are essential.

How are HSS drills used?

The correct use of HSS drills is crucial to achieving optimum results and prolonging the life of the tool. Before starting drilling, it is important to select the appropriate HSS drill according to the material to be machined and the diameter of the desired hole. It is advisable to use a drill press or hand drill with adjustable speed to control the rotation speed and pressure applied.

During drilling, it is essential to maintain adequate lubrication to reduce friction and heat generated, thus preventing the drill from overheating. In addition, it is important to apply constant and even pressure to prevent the drill from breaking and ensure a clean and accurate hole.

Advantages of HSS drills

HSS drills offer numerous advantages over other drill bit types, making them a preferred choice for many machine shops. Some of the main advantages include:

1. Heat resistance: HSS drills retain their hardness even at high temperatures, allowing them to work at higher speeds without compromising cutting quality.

2. Durability: due to their super-fast steel composition, HSS drills offer greater wear resistance and a longer service life than other drills.

3. Versatility: HSS drills are suitable for a wide range of materials, making them a versatile solution for different applications.

4. Precision: HSS drills guarantee precise, clean holes, essential for applications requiring tight tolerances.

5. Cost-effective: although the initial cost may be higher than other drills, the durability and performance of HSS drills make them an economical choice in the long term.

Frequently asked questions about HSS drills

1. What is the difference between HSS and carbide drills?

HSS drills are made of high-speed steel, while carbide drills are made of tungsten carbide. Carbide drills offer greater hardness and wear resistance, but are more brittle and expensive than HSS drills. HSS drills are more versatile and suitable for general applications, while carbide drills are ideal for hard, abrasive materials.

2. How can I extend the life of my HSS drill bits?

To prolong the life of HSS drills, it is important to use proper lubrication when drilling, apply constant and even pressure, and choose the appropriate rotational speed according to the material. In addition, it is advisable to sharpen your drills regularly to maintain their efficiency.

3. Are HSS drills suitable for drilling stainless steel?

Yes, HSS drills can be used for drilling stainless steel, but it is important to choose a high quality HSS drill and use adequate lubrication to reduce friction and heat generated during drilling.

4. What are the standard sizes of HSS drill bits?

HSS drills are available in a wide range of sizes, from very small diameters for precision applications to larger diameters for larger holes. Standard sizes vary depending on the measuring system used (metric or imperial) and the specific requirements of the application.

5. Can I use HSS drills on a cordless drill?

Yes, HSS drills can be used on cordless drills, provided the drill is capable of providing the speed and torque required to drill the desired material. It is important to adjust the speed and apply adequate pressure to achieve optimal results.

In conclusion, HSS drills are an excellent choice for machine shops looking for reliable, versatile and durable drilling tools. With proper selection and use, HSS drills can significantly improve the quality and efficiency of drilling operations, contributing to the overall success of production activities.

Read More Read Less