< Clamping systems Self centering chucks

Self-centring chucks are an essential component in machine shops, where precision and reliability are fundamental requirements to guarantee the quality of the work performed. These devices, mainly used in turning operations, are designed to hold the workpiece firmly in position, allowing for smooth and precise rotation. In this in-depth look, we will explore in detail what self-centring chucks are, how they work, their advantages and main applications, as well as answer some of the most frequently asked questions on this topic.

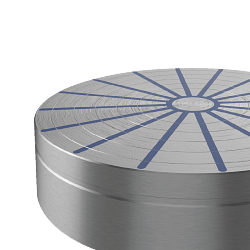

Understanding self-centring chucks

Self-centring chucks are mechanical devices used to automatically clamp and centre a workpiece on a machine tool, such as a lathe. Their main characteristic is their ability to centre the workpiece automatically, thanks to a system of jaws that move simultaneously towards the centre of the chuck. This synchronised movement is made possible by a spiral or rack and pinion mechanism, which ensures that all jaws move at the same speed and distance.

Operation and use of self-centring chucks

The operation of self-centring chucks is based on a simple but effective principle: when the operator actuates the chuck, the jaws move simultaneously towards the centre, locking the workpiece in position. This process ensures that the workpiece is precisely centred in relation to the lathe's axis of rotation, minimising vibration and improving machining quality.

Self-centring chucks are used in a wide range of industrial applications, including the production of automotive, aerospace and heavy machinery components. They are particularly valued for their ability to reduce setup times and improve operational efficiency, as they allow parts to be changed quickly without having to manually adjust each jaw.

Advantages of self-centring chucks

The use of self-centring chucks offers numerous advantages, including:

1. Accuracy and repeatability: Due to their design, self-centring chucks ensure accurate and repeatable centring of the workpiece, minimising machining errors and improving the quality of the final product.

2. Operational efficiency: The ability to automatically centre the workpiece reduces setup times and allows for rapid changeover from one workpiece to another, increasing overall workshop productivity.

3. Versatility: Self-centring chucks are available in different sizes and configurations, making them suitable for a wide range of applications and materials.

4. Safety: Safe workpiece clamping reduces the risk of accidents during machining, protecting both the operator and the machine tool.

Frequently asked questions about chucks

1. What is the difference between a self-centring chuck and an independent chuck?

Self-centring chucks have jaws that move simultaneously to automatically centre the workpiece, whereas independent chucks allow each jaw to be adjusted separately, offering more flexibility but requiring more time to set up.

2. How do I choose the right chuck for a specific application?

The choice of a chuck depends on several factors, including the size and shape of the workpiece, the material to be machined and the specifications of the machine tool. It is also important to consider the required clamping force and maximum rotation speed.

3. What maintenance is required to ensure the proper functioning of a chuck?

Regular maintenance is essential to ensure the proper functioning of self-centring chucks. This includes cleaning the jaws and internal mechanism, lubricating the moving parts and periodically inspecting for signs of wear or damage.

4. Can chucks be used on CNC machines?

Yes, self-centring chucks are widely used on CNC machines, where their ability to automatically centre the workpiece helps improve the accuracy and efficiency of machining operations.

5. What are the limitations of self-centring chucks?

Although self-centring chucks offer many advantages, they do have some limitations, such as the difficulty in machining workpieces with irregular shapes or delicate surfaces that could be damaged by jaw pressure.

Conclusion

Self-centring chucks are indispensable tools in modern machine shops, where precision and efficiency are key to success. Thanks to their ability to automatically centre parts, these devices improve machining quality and reduce setup times, helping to increase overall productivity. With proper maintenance and a judicious choice of the most suitable chuck for specific needs, workshops can take full advantage of the use of self-centring chucks, guaranteeing excellent results in every turning operation.

Read More Read Less