< Solid cutting tools Taps for threading

Taps are indispensable tools for any professional machine shop. Used to create internal threads in holes, taps ensure precision and reliability across a wide range of industrial applications. Whether for a construction project or a repair task, having high-quality taps is essential to achieve optimal results.

What is a tap and how does it work?

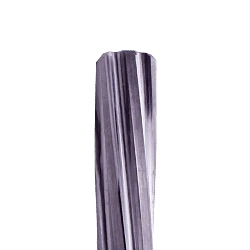

A tap is a cylindrical tool equipped with sharp helical flutes, designed to create internal threads in pre-drilled holes. During use, the tap is screwed into the hole, removing material to form the desired thread. This process is crucial to ensure that screws or bolts can be inserted with precision and stability, guaranteeing a secure and durable assembly.

Benefits of taps:

Precision and Reliability: High-quality taps ensure precise and uniform threading, minimizing the risk of damaging components or materials. This is fundamental to maintaining the structural integrity of finished products.

Versatility: Available in various sizes and configurations, taps can be used on a wide range of materials, including steel, aluminum, and plastic. This versatility makes them essential tools for numerous mechanical applications.

Operational Efficiency: Using the appropriate taps makes threading operations faster and more efficient, enhancing overall productivity. Additionally, this saves valuable time and resources, optimizing machining processes.

Durability: Made from highly wear-resistant materials, taps offer long-lasting performance even under intensive working conditions. This translates to less frequent replacements and a consequent reduction in operational costs.

In machine shops, taps are indispensable for a variety of operations, from vehicle repair to the production of industrial components. Their ability to create precise threads makes them ideal for critical assemblies, where safety and reliability are paramount. Employing high-quality taps is synonymous with precision and durability, key elements for the success of any mechanical project.

Read More Read Less