Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

02.927371

- Supporting big orders

02.38298620

-

info@linkindustrialtools.it

- Request assistance with form

Or contact us with the chat in the lower right corner

< Abrasives

Diamond grinding wheels

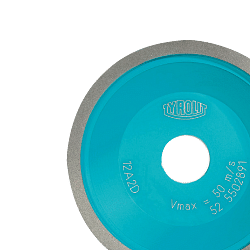

Professional diamond grinding wheels: an innovation that has revolutionised the world of machine shops. These tools, essential for machining hard, tough materials, represent an advanced solution for those seeking precision and durability. But what exactly are diamond grinding wheels and why are they so popular in industry?

Understanding diamond grinding wheels

Diamond grinding wheels are abrasive tools consisting of a metal or resin backing onto which diamond granules are fixed. Diamond, known to be the hardest material known, gives these grinding wheels unrivalled cutting capacity and wear resistance. Used primarily for machining extremely hard materials such as ceramics, glass, tungsten carbide and hard metals, diamond grinding wheels are indispensable in many industrial applications.

Applications of diamond grinding wheels in machine shops

In machine shops, diamond grinding wheels are used in a wide range of operations. They are used to sharpen tools, grind surfaces, cut hard materials and polish complex surfaces. Their ability to maintain a precise shape and provide a high quality finish makes them ideal for machining operations requiring tight tolerances and smooth surfaces.

Advantages of diamond grinding wheels

One of the main advantages of diamond grinding wheels is their durability. Thanks to the strength of the diamond, these grinding wheels offer a significantly longer service life than conventional wheels. This translates into reduced downtime and replacement costs. In addition, diamond grinding wheels guarantee superior machining precision, minimising vibration and improving surface finish quality.

Correct use of diamond grinding wheels

To get the most out of diamond grinding wheels, it is essential to use them correctly. It is important to choose the appropriate grit and bond according to the material to be machined and the specific application. In addition, it is essential to maintain an adequate rotational speed and use an effective cooling system to prevent overheating and premature wear of the grinding wheel.

Frequently asked questions about diamond grinding wheels

Many professionals ask questions about the use and maintenance of diamond grinding wheels. One of the most common questions concerns the choice between metal bond and resin bond. In general, metal-bonded grinding wheels are more suitable for applications requiring greater wear resistance, while resin-bonded wheels offer greater flexibility and are ideal for work requiring a finer finish.

Another frequent question concerns the need for a cooling system. Although not always mandatory, the use of a cooling system can prolong the life of the grinding wheel and improve the quality of machining by reducing the risk of overheating and deformation of the workpiece.

Conclusion: the importance of diamond grinding wheels in machine shops

Professional diamond grinding wheels are an essential investment for machine shops wishing to improve the efficiency and quality of their machining operations. Thanks to their durability, precision and versatility, these grinding wheels have become an indispensable tool for those working with hard and complex materials. Choosing the right diamond wheel and using it correctly can make the difference between mediocre and excellent machining.

Read More Read LessUnderstanding diamond grinding wheels

Diamond grinding wheels are abrasive tools consisting of a metal or resin backing onto which diamond granules are fixed. Diamond, known to be the hardest material known, gives these grinding wheels unrivalled cutting capacity and wear resistance. Used primarily for machining extremely hard materials such as ceramics, glass, tungsten carbide and hard metals, diamond grinding wheels are indispensable in many industrial applications.

Applications of diamond grinding wheels in machine shops

In machine shops, diamond grinding wheels are used in a wide range of operations. They are used to sharpen tools, grind surfaces, cut hard materials and polish complex surfaces. Their ability to maintain a precise shape and provide a high quality finish makes them ideal for machining operations requiring tight tolerances and smooth surfaces.

Advantages of diamond grinding wheels

One of the main advantages of diamond grinding wheels is their durability. Thanks to the strength of the diamond, these grinding wheels offer a significantly longer service life than conventional wheels. This translates into reduced downtime and replacement costs. In addition, diamond grinding wheels guarantee superior machining precision, minimising vibration and improving surface finish quality.

Correct use of diamond grinding wheels

To get the most out of diamond grinding wheels, it is essential to use them correctly. It is important to choose the appropriate grit and bond according to the material to be machined and the specific application. In addition, it is essential to maintain an adequate rotational speed and use an effective cooling system to prevent overheating and premature wear of the grinding wheel.

Frequently asked questions about diamond grinding wheels

Many professionals ask questions about the use and maintenance of diamond grinding wheels. One of the most common questions concerns the choice between metal bond and resin bond. In general, metal-bonded grinding wheels are more suitable for applications requiring greater wear resistance, while resin-bonded wheels offer greater flexibility and are ideal for work requiring a finer finish.

Another frequent question concerns the need for a cooling system. Although not always mandatory, the use of a cooling system can prolong the life of the grinding wheel and improve the quality of machining by reducing the risk of overheating and deformation of the workpiece.

Conclusion: the importance of diamond grinding wheels in machine shops

Professional diamond grinding wheels are an essential investment for machine shops wishing to improve the efficiency and quality of their machining operations. Thanks to their durability, precision and versatility, these grinding wheels have become an indispensable tool for those working with hard and complex materials. Choosing the right diamond wheel and using it correctly can make the difference between mediocre and excellent machining.