Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

02.927371

- Supporting big orders

02.38298620

-

info@linkindustrialtools.it

- Request assistance with form

Or contact us with the chat in the lower right corner

< Abrasives

Cutting discs

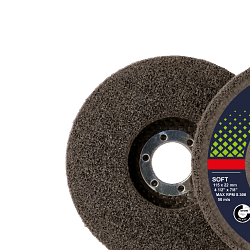

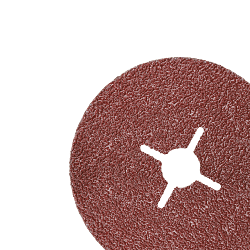

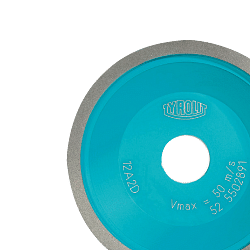

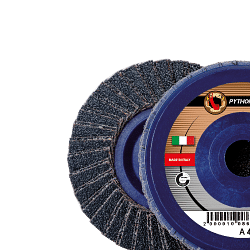

Professional metal cutting discs are an essential tool for machine shops and industries working with metal materials. These discs, designed for precision and durability, are essential for ensuring clean and precise cuts on a wide range of metals. In this in-depth article, we will explore the features, use and advantages of professional metal cutting discs, and also answer frequently asked questions on this topic.

Features of professional metal cutting discs

Metal cutting discs are designed to withstand the high temperatures and mechanical stresses that occur when cutting hard materials. They are made of high-quality abrasive materials, such as aluminium oxide or silicon carbide, which guarantee a long service life and high cutting efficiency. The choice of abrasive material depends on the type of metal to be cut; for example, aluminium oxide is ideal for steel, while silicon carbide is more suitable for non-ferrous metals.

Use of metal cutting discs in machine shops

In machine shops, metal cutting discs are used for a variety of applications, including cutting pipes, sheet metal, bars and metal profiles. The correct use of these discs requires a thorough knowledge of cutting techniques and the specifications of the disc itself. It is essential to select the right disc according to the type of metal and the thickness of the material to be cut. In addition, it is important to use personal protective equipment, such as safety goggles and gloves, to prevent injuries during the cutting process.

Advantages of professional metal cutting discs

The use of professional metal cutting discs offers numerous advantages. Firstly, they guarantee a clean and precise cut, minimising the need for further processing. This translates into time and cost savings for machine shops. In addition, high-quality discs are designed to last longer, reducing the frequency of replacement and, consequently, operating costs. Another significant advantage is safety: professional discs are tested to withstand extreme working conditions, reducing the risk of sudden breakage.

Frequently asked questions about metal cutting discs

1. What is the difference between a cut-off wheel for metal and one for other materials?

Metal cutting discs are specifically designed to withstand the stresses of cutting metal materials, whereas discs for other materials may not have the same strength and durability.

2. How do I choose the right cutting disc for a particular metal?

The choice of disc depends on the type of metal and the thickness of the material. It is important to consult the manufacturer's specifications to select the most suitable disc.

3. What safety measures should be taken when using cutting discs?

It is essential to wear personal protective equipment, such as safety glasses and gloves, and to ensure that the equipment is in good working order.

4. How long does a metal cutting disc last?

The lifetime of a disc depends on the quality of the abrasive material and the intensity of use. Professional discs tend to last longer than those of lower quality.

5. Can a metal cutting disc be used on other materials?

Although it is possible, it is not recommended, as metal discs are optimised for cutting metals and may not offer the same performance on other materials.

Conclusion

Professional metal cutting discs are indispensable tools for machine shops and industries working with metal materials. Their ability to offer precise and durable cuts makes them an excellent choice for those seeking efficiency and quality. Understanding the characteristics, use and advantages of these discs is crucial to optimising machining processes and ensuring safety at work. With the right knowledge and equipment, metal cutting discs can significantly improve productivity and quality of work in machine shops.

Read More Read LessFeatures of professional metal cutting discs

Metal cutting discs are designed to withstand the high temperatures and mechanical stresses that occur when cutting hard materials. They are made of high-quality abrasive materials, such as aluminium oxide or silicon carbide, which guarantee a long service life and high cutting efficiency. The choice of abrasive material depends on the type of metal to be cut; for example, aluminium oxide is ideal for steel, while silicon carbide is more suitable for non-ferrous metals.

Use of metal cutting discs in machine shops

In machine shops, metal cutting discs are used for a variety of applications, including cutting pipes, sheet metal, bars and metal profiles. The correct use of these discs requires a thorough knowledge of cutting techniques and the specifications of the disc itself. It is essential to select the right disc according to the type of metal and the thickness of the material to be cut. In addition, it is important to use personal protective equipment, such as safety goggles and gloves, to prevent injuries during the cutting process.

Advantages of professional metal cutting discs

The use of professional metal cutting discs offers numerous advantages. Firstly, they guarantee a clean and precise cut, minimising the need for further processing. This translates into time and cost savings for machine shops. In addition, high-quality discs are designed to last longer, reducing the frequency of replacement and, consequently, operating costs. Another significant advantage is safety: professional discs are tested to withstand extreme working conditions, reducing the risk of sudden breakage.

Frequently asked questions about metal cutting discs

1. What is the difference between a cut-off wheel for metal and one for other materials?

Metal cutting discs are specifically designed to withstand the stresses of cutting metal materials, whereas discs for other materials may not have the same strength and durability.

2. How do I choose the right cutting disc for a particular metal?

The choice of disc depends on the type of metal and the thickness of the material. It is important to consult the manufacturer's specifications to select the most suitable disc.

3. What safety measures should be taken when using cutting discs?

It is essential to wear personal protective equipment, such as safety glasses and gloves, and to ensure that the equipment is in good working order.

4. How long does a metal cutting disc last?

The lifetime of a disc depends on the quality of the abrasive material and the intensity of use. Professional discs tend to last longer than those of lower quality.

5. Can a metal cutting disc be used on other materials?

Although it is possible, it is not recommended, as metal discs are optimised for cutting metals and may not offer the same performance on other materials.

Conclusion

Professional metal cutting discs are indispensable tools for machine shops and industries working with metal materials. Their ability to offer precise and durable cuts makes them an excellent choice for those seeking efficiency and quality. Understanding the characteristics, use and advantages of these discs is crucial to optimising machining processes and ensuring safety at work. With the right knowledge and equipment, metal cutting discs can significantly improve productivity and quality of work in machine shops.