Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

02.927371

- Supporting big orders

02.38298620

-

info@linkindustrialtools.it

- Request assistance with form

Or contact us with the chat in the lower right corner

< Abrasives

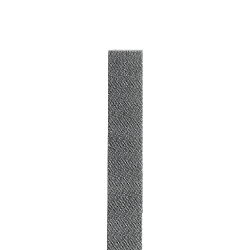

Abrasive cloth in rolls, sheets and bands

Abrasive cloths in rolls, sheets and belts are an essential element in the landscape of machine shops and manufacturing industries. These tools, although often undervalued, play a crucial role in ensuring the quality and efficiency of metalworking processes and other materials. In this in-depth look, we will explore in detail what abrasive cloths are, what they are used for, how they are used and what advantages they offer, while also answering the most frequently asked questions in the industry.

Understanding abrasive cloths: an essential overview

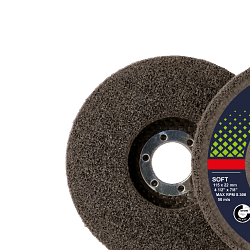

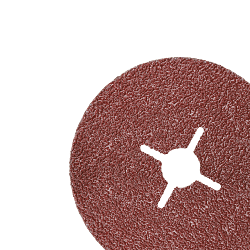

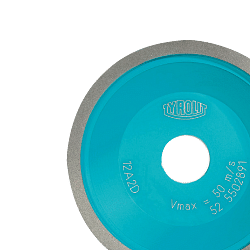

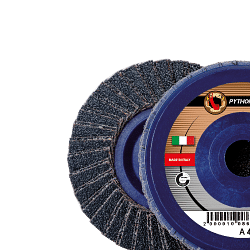

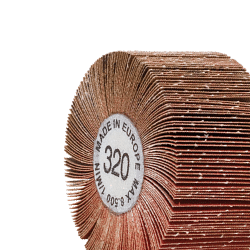

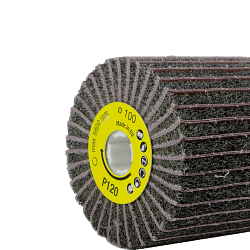

Abrasive cloths are consumables used for finishing and surface processing of various materials, including metals, wood and plastics. They consist of a flexible backing, usually fabric, onto which abrasive granules are applied. These grains can be of different materials, such as aluminium oxide, silicon carbide or zirconium, each with specific properties that make them suitable for particular applications.

Applications of abrasive cloths in machine shops

In machine shops, abrasive cloths are used in a wide range of applications. They are used for removing burrs, sanding, polishing and preparing surfaces for further treatment, such as painting or plating. The choice of abrasive cloth type depends on the material to be processed and the desired degree of finish. For example, coarser grains are preferred for removing excess material on metal surfaces, while finer grains are used for final polishing.

Advantages of using abrasive cloths in rolls, sheets and belts

The use of abrasive cloths in rolls, sheets and belts offers numerous advantages. Firstly, the flexibility of the backing allows it to easily adapt to uneven surfaces, ensuring a uniform finish. In addition, the availability in different shapes and sizes makes it possible to choose the most suitable format for the specific needs of the job. Rolls, for example, are ideal for large-scale applications, while sheets and belts are more suitable for precision work or on smaller surfaces.

How to choose the right abrasive cloth for your project

Choosing the right abrasive cloth is crucial for optimal results. It is important to consider several factors, including the type of material to be worked on, the degree of abrasiveness required and the product's durability. Abrasive cloths with aluminium oxide granules are generally suitable for working ferrous metals, while those with silicon carbide are preferable for harder materials such as glass or ceramics. Furthermore, the choice of backing material is crucial: a stiffer backing material offers greater stability, while a more flexible one allows better adaptability to curved surfaces.

Frequently asked questions on the use of abrasive cloths

1. What is the difference between an abrasive cloth and an abrasive paper?

The main difference lies in the backing: abrasive cloth uses a cloth backing, whereas abrasive paper uses a paper backing. Abrasive cloth is generally stronger and more flexible, making it suitable for more demanding applications.

2. How is abrasive cloth stored correctly?

It is important to store abrasive cloths in a dry, temperature-controlled environment to prevent moisture from impairing the effectiveness of the abrasive grains. It is also advisable to store them in a place away from sources of excessive heat.

3. How long does an abrasive cloth last?

The lifetime of an abrasive cloth depends on the intensity and frequency of use, as well as the type of material being processed. It is important to monitor the wear of the grains and replace the cloth when it no longer provides an adequate finish.

Innovations in the abrasive cloth sector

In recent years, the abrasive cloth sector has seen significant innovations, with the development of new materials and technologies that improve the efficiency and durability of products. For example, the introduction of ceramic abrasive grains has resulted in longer life and better cutting performance, while reducing the heat generated during processing. These innovations not only improve the quality of work, but also contribute to lower operating costs due to a reduced need for consumable replacement.

Conclusion: the importance of abrasive cloths in the production process

In conclusion, abrasive cloths in rolls, sheets and belts are indispensable tools in machine shops and manufacturing industries. Their ability to adapt to different applications and materials makes them a key element in ensuring the quality and efficiency of production processes. Choosing the right abrasive cloth and using it correctly can make the difference between a mediocre job and an excellent one, contributing to the company's overall success. As technologies and materials continue to evolve, abrasive cloths will continue to play a crucial role in the future of industrial machining.

Read More Read LessUnderstanding abrasive cloths: an essential overview

Abrasive cloths are consumables used for finishing and surface processing of various materials, including metals, wood and plastics. They consist of a flexible backing, usually fabric, onto which abrasive granules are applied. These grains can be of different materials, such as aluminium oxide, silicon carbide or zirconium, each with specific properties that make them suitable for particular applications.

Applications of abrasive cloths in machine shops

In machine shops, abrasive cloths are used in a wide range of applications. They are used for removing burrs, sanding, polishing and preparing surfaces for further treatment, such as painting or plating. The choice of abrasive cloth type depends on the material to be processed and the desired degree of finish. For example, coarser grains are preferred for removing excess material on metal surfaces, while finer grains are used for final polishing.

Advantages of using abrasive cloths in rolls, sheets and belts

The use of abrasive cloths in rolls, sheets and belts offers numerous advantages. Firstly, the flexibility of the backing allows it to easily adapt to uneven surfaces, ensuring a uniform finish. In addition, the availability in different shapes and sizes makes it possible to choose the most suitable format for the specific needs of the job. Rolls, for example, are ideal for large-scale applications, while sheets and belts are more suitable for precision work or on smaller surfaces.

How to choose the right abrasive cloth for your project

Choosing the right abrasive cloth is crucial for optimal results. It is important to consider several factors, including the type of material to be worked on, the degree of abrasiveness required and the product's durability. Abrasive cloths with aluminium oxide granules are generally suitable for working ferrous metals, while those with silicon carbide are preferable for harder materials such as glass or ceramics. Furthermore, the choice of backing material is crucial: a stiffer backing material offers greater stability, while a more flexible one allows better adaptability to curved surfaces.

Frequently asked questions on the use of abrasive cloths

1. What is the difference between an abrasive cloth and an abrasive paper?

The main difference lies in the backing: abrasive cloth uses a cloth backing, whereas abrasive paper uses a paper backing. Abrasive cloth is generally stronger and more flexible, making it suitable for more demanding applications.

2. How is abrasive cloth stored correctly?

It is important to store abrasive cloths in a dry, temperature-controlled environment to prevent moisture from impairing the effectiveness of the abrasive grains. It is also advisable to store them in a place away from sources of excessive heat.

3. How long does an abrasive cloth last?

The lifetime of an abrasive cloth depends on the intensity and frequency of use, as well as the type of material being processed. It is important to monitor the wear of the grains and replace the cloth when it no longer provides an adequate finish.

Innovations in the abrasive cloth sector

In recent years, the abrasive cloth sector has seen significant innovations, with the development of new materials and technologies that improve the efficiency and durability of products. For example, the introduction of ceramic abrasive grains has resulted in longer life and better cutting performance, while reducing the heat generated during processing. These innovations not only improve the quality of work, but also contribute to lower operating costs due to a reduced need for consumable replacement.

Conclusion: the importance of abrasive cloths in the production process

In conclusion, abrasive cloths in rolls, sheets and belts are indispensable tools in machine shops and manufacturing industries. Their ability to adapt to different applications and materials makes them a key element in ensuring the quality and efficiency of production processes. Choosing the right abrasive cloth and using it correctly can make the difference between a mediocre job and an excellent one, contributing to the company's overall success. As technologies and materials continue to evolve, abrasive cloths will continue to play a crucial role in the future of industrial machining.