Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

02.927371

- Supporting big orders

02.38298620

-

info@linkindustrialtools.it

- Request assistance with form

Or contact us with the chat in the lower right corner

< Lifting systems

- Home

- Lifting systems

- Pneumatic balancers

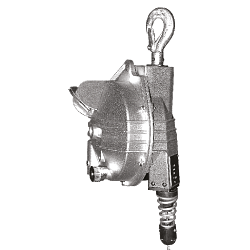

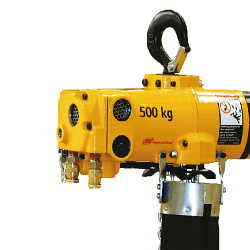

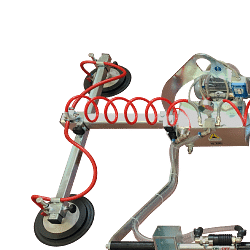

Pneumatic balancers

Pneumatic balancers are an essential component in the modern machine shop landscape, offering advanced solutions for handling and lifting heavy loads. Thanks to their sophisticated technology, these tools improve operational efficiency and safety in the workplace. In this in-depth look, we will explore in detail what pneumatic balancers are, how they work, their advantages and practical applications in machine shops.

Introduction to pneumatic balancers

Pneumatic balancers are devices designed to lift and handle heavy loads with precision and ease. They use compressed air as an energy source to balance the weight of the load, allowing operators to move it with minimal effort. This technology is particularly useful in industrial environments where handling heavy components is a daily necessity.

How pneumatic balancers work

The operating principle of pneumatic balancers is based on the use of a pneumatic cylinder connected to a control system that regulates air pressure. When a load is attached to the balancer, the system detects the weight and automatically adjusts the pressure to balance the load. This allows the operator to lift, lower and move the load precisely, without having to apply excessive force.

Advantages of pneumatic balancers

The adoption of pneumatic balancers in machine shops offers numerous advantages. First of all, they improve workplace safety by reducing the risk of accidents related to manual lifting of heavy loads. They also increase operational efficiency, as they allow components to be moved quickly without interruption. Precise positioning of loads is another significant benefit, particularly important in applications requiring accurate alignment.

Practical applications in machine shops

In machine shops, pneumatic balancers find application in various operations. They are used for the assembly of heavy components, such as engines and transmissions, where precision and safety are paramount. They are also used in the handling of heavy equipment and tools, facilitating the work of operators and reducing the time needed to complete operations.

Frequently asked questions about pneumatic balancers

1. What is the lifting capacity of a pneumatic balancer?

The lifting capacity varies depending on the model and manufacturer, but can generally range from a few kilograms to several tonnes.

2. Do pneumatic balancers require maintenance?

Yes, like any industrial equipment, pneumatic balancers require regular maintenance to ensure optimal operation and extend their service life.

3. Can they be used in extreme environments?

Many pneumatic balancers are designed to withstand harsh environmental conditions, but it is important to check the product specifications to ensure that they are suitable for the specific working environment.

Conclusion

Pneumatic balancers are indispensable tools in modern machine shops, offering advanced solutions for handling heavy loads. With their ability to improve safety and operational efficiency, they are a valuable investment for any company wishing to optimise its production processes. With a thorough understanding of how they work and the benefits they offer, workshops can fully exploit the potential of these innovative devices.

Read More Read LessIntroduction to pneumatic balancers

Pneumatic balancers are devices designed to lift and handle heavy loads with precision and ease. They use compressed air as an energy source to balance the weight of the load, allowing operators to move it with minimal effort. This technology is particularly useful in industrial environments where handling heavy components is a daily necessity.

How pneumatic balancers work

The operating principle of pneumatic balancers is based on the use of a pneumatic cylinder connected to a control system that regulates air pressure. When a load is attached to the balancer, the system detects the weight and automatically adjusts the pressure to balance the load. This allows the operator to lift, lower and move the load precisely, without having to apply excessive force.

Advantages of pneumatic balancers

The adoption of pneumatic balancers in machine shops offers numerous advantages. First of all, they improve workplace safety by reducing the risk of accidents related to manual lifting of heavy loads. They also increase operational efficiency, as they allow components to be moved quickly without interruption. Precise positioning of loads is another significant benefit, particularly important in applications requiring accurate alignment.

Practical applications in machine shops

In machine shops, pneumatic balancers find application in various operations. They are used for the assembly of heavy components, such as engines and transmissions, where precision and safety are paramount. They are also used in the handling of heavy equipment and tools, facilitating the work of operators and reducing the time needed to complete operations.

Frequently asked questions about pneumatic balancers

1. What is the lifting capacity of a pneumatic balancer?

The lifting capacity varies depending on the model and manufacturer, but can generally range from a few kilograms to several tonnes.

2. Do pneumatic balancers require maintenance?

Yes, like any industrial equipment, pneumatic balancers require regular maintenance to ensure optimal operation and extend their service life.

3. Can they be used in extreme environments?

Many pneumatic balancers are designed to withstand harsh environmental conditions, but it is important to check the product specifications to ensure that they are suitable for the specific working environment.

Conclusion

Pneumatic balancers are indispensable tools in modern machine shops, offering advanced solutions for handling heavy loads. With their ability to improve safety and operational efficiency, they are a valuable investment for any company wishing to optimise its production processes. With a thorough understanding of how they work and the benefits they offer, workshops can fully exploit the potential of these innovative devices.