Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

02.927371

- Supporting big orders

02.38298620

-

info@linkindustrialtools.it

- Request assistance with form

Or contact us with the chat in the lower right corner

< Lifting systems

- Home

- Lifting systems

- Magnetic lifters

Magnetic lifters

Professional magnetic lifters: a complete guide for machine shops

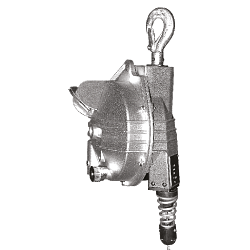

In the world of machine shops, efficiency and safety are two fundamental pillars for successful operations. Professional magnetic lifters represent an innovative and reliable solution for lifting and handling ferrous materials. These tools, with their ability to lift heavy loads without the aid of hooks or chains, are revolutionising the way workshops manage their daily processes.

What are professional magnetic lifters?

Professional magnetic lifters are devices designed to lift and move ferrous materials using magnetic force. These tools consist of a powerful permanent magnet or electromagnet, which generates a magnetic field that attracts and firmly holds the material to be lifted. Their compact and robust design makes them ideal for use in industrial environments where space is often limited and safety is a priority.

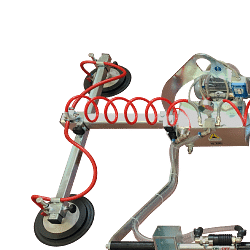

Applications and use of magnetic lifters

The applications of magnetic lifters are many and vary depending on the specific needs of the workshop. They are commonly used for lifting sheet metal, bars, pipes and other metal components. Due to their versatility, they can be used at different stages of the production process, from the handling of raw materials to the handling of finished products.

The use of magnetic lifters is simple and intuitive. Once the lifter is placed on the material to be lifted, the magnetic field is activated, allowing the device to adhere firmly to the load. To release the material, simply deactivate the magnetic field, ensuring a quick and safe operation.

Advantages of professional magnetic lifters

The adoption of professional magnetic lifters offers several advantages to machine shops. Firstly, they significantly improve operational efficiency by reducing the time required for lifting and handling materials. This translates into increased productivity and reduced operating costs.

In addition, magnetic lifters help to improve safety at work. By eliminating the need for hooks, chains and other traditional lifting devices, they reduce the risk of accidents and injuries. Their ability to lift heavy loads with ease also reduces the physical effort required of operators, helping to prevent musculoskeletal injuries.

Technical considerations and maintenance

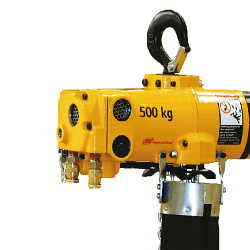

When choosing a magnetic lifter, it is important to consider several technical factors, including the lifting capacity, the type of magnet used and the characteristics of the material to be lifted. The lifting capacity must be appropriate for the maximum weight of the load, while the type of magnet (permanent or electromagnet) affects the versatility and efficiency of the device.

Maintenance of magnetic lifters is essential to ensure their longevity and efficiency. It is important to carry out regular checks to verify the integrity of the magnet and mechanical components. Furthermore, it is advisable to follow the manufacturer's instructions for cleaning and storing the device in order to prevent damage and malfunctioning.

Frequently asked questions about magnetic lifters

1. What is the difference between a permanent magnet and an electromagnet?

A permanent magnet generates a constant magnetic field without the need for a power supply, whereas an electromagnet requires electricity to generate the magnetic field. Electromagnets offer more control and flexibility, but require a power source.

2. Can magnetic lifters lift any kind of metal?

Magnetic lifters are designed to lift ferrous materials, such as steel and iron. They are not effective on non-ferrous metals, such as aluminium and copper, which are not attracted to the magnet.

3. What safety measures should be taken when using magnetic lifters?

It is important to follow the manufacturer's guidelines and ensure that the lifter is used by properly trained personnel. In addition, it is essential to check that the load is well balanced and that the surrounding area is free of obstacles.

4. How do you determine the lifting capacity required for a specific application?

The lifting capacity must be chosen according to the maximum weight of the load to be lifted. It is advisable to opt for a lift with a capacity slightly above the intended maximum weight in order to provide a safety margin.

5. Can magnetic lifters be used outdoors?

Yes, many magnetic lifters are designed to withstand adverse environmental conditions and can be used outdoors. However, it is important to check the product specifications and take the necessary precautions to protect the device from the elements.

Conclusions

Professional magnetic lifters are an advanced and safe solution for machine shops wishing to optimise their lifting and handling processes. Thanks to their efficiency, safety and ease of use, these devices are becoming increasingly popular in the industrial sector. Investing in high-quality magnetic lifters can lead to significant improvements in productivity and safety, making daily operations smoother and more reliable.

Read More Read LessIn the world of machine shops, efficiency and safety are two fundamental pillars for successful operations. Professional magnetic lifters represent an innovative and reliable solution for lifting and handling ferrous materials. These tools, with their ability to lift heavy loads without the aid of hooks or chains, are revolutionising the way workshops manage their daily processes.

What are professional magnetic lifters?

Professional magnetic lifters are devices designed to lift and move ferrous materials using magnetic force. These tools consist of a powerful permanent magnet or electromagnet, which generates a magnetic field that attracts and firmly holds the material to be lifted. Their compact and robust design makes them ideal for use in industrial environments where space is often limited and safety is a priority.

Applications and use of magnetic lifters

The applications of magnetic lifters are many and vary depending on the specific needs of the workshop. They are commonly used for lifting sheet metal, bars, pipes and other metal components. Due to their versatility, they can be used at different stages of the production process, from the handling of raw materials to the handling of finished products.

The use of magnetic lifters is simple and intuitive. Once the lifter is placed on the material to be lifted, the magnetic field is activated, allowing the device to adhere firmly to the load. To release the material, simply deactivate the magnetic field, ensuring a quick and safe operation.

Advantages of professional magnetic lifters

The adoption of professional magnetic lifters offers several advantages to machine shops. Firstly, they significantly improve operational efficiency by reducing the time required for lifting and handling materials. This translates into increased productivity and reduced operating costs.

In addition, magnetic lifters help to improve safety at work. By eliminating the need for hooks, chains and other traditional lifting devices, they reduce the risk of accidents and injuries. Their ability to lift heavy loads with ease also reduces the physical effort required of operators, helping to prevent musculoskeletal injuries.

Technical considerations and maintenance

When choosing a magnetic lifter, it is important to consider several technical factors, including the lifting capacity, the type of magnet used and the characteristics of the material to be lifted. The lifting capacity must be appropriate for the maximum weight of the load, while the type of magnet (permanent or electromagnet) affects the versatility and efficiency of the device.

Maintenance of magnetic lifters is essential to ensure their longevity and efficiency. It is important to carry out regular checks to verify the integrity of the magnet and mechanical components. Furthermore, it is advisable to follow the manufacturer's instructions for cleaning and storing the device in order to prevent damage and malfunctioning.

Frequently asked questions about magnetic lifters

1. What is the difference between a permanent magnet and an electromagnet?

A permanent magnet generates a constant magnetic field without the need for a power supply, whereas an electromagnet requires electricity to generate the magnetic field. Electromagnets offer more control and flexibility, but require a power source.

2. Can magnetic lifters lift any kind of metal?

Magnetic lifters are designed to lift ferrous materials, such as steel and iron. They are not effective on non-ferrous metals, such as aluminium and copper, which are not attracted to the magnet.

3. What safety measures should be taken when using magnetic lifters?

It is important to follow the manufacturer's guidelines and ensure that the lifter is used by properly trained personnel. In addition, it is essential to check that the load is well balanced and that the surrounding area is free of obstacles.

4. How do you determine the lifting capacity required for a specific application?

The lifting capacity must be chosen according to the maximum weight of the load to be lifted. It is advisable to opt for a lift with a capacity slightly above the intended maximum weight in order to provide a safety margin.

5. Can magnetic lifters be used outdoors?

Yes, many magnetic lifters are designed to withstand adverse environmental conditions and can be used outdoors. However, it is important to check the product specifications and take the necessary precautions to protect the device from the elements.

Conclusions

Professional magnetic lifters are an advanced and safe solution for machine shops wishing to optimise their lifting and handling processes. Thanks to their efficiency, safety and ease of use, these devices are becoming increasingly popular in the industrial sector. Investing in high-quality magnetic lifters can lead to significant improvements in productivity and safety, making daily operations smoother and more reliable.