Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

02.927371

- Supporting big orders

02.38298620

-

info@linkindustrialtools.it

- Request assistance with form

Or contact us with the chat in the lower right corner

< Lifting systems

- Home

- Lifting systems

- Lift trucks

Lift trucks

Hoist trolleys are a key element in the landscape of machine shops and industries that require efficient load handling solutions. These devices, designed to facilitate the movement of hoists along a beam, are essential for optimising production processes and ensuring operational safety. In this in-depth look, we will explore in detail what hoist trolleys are, how they are used, the advantages they offer and answer the most frequently asked questions on this topic.

What are hoist trolleys?

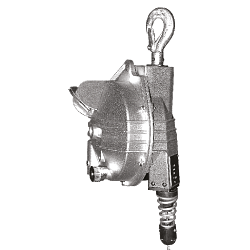

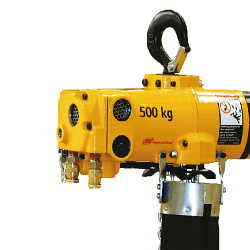

Hoist trolleys are mechanical devices designed to enable the horizontal movement of a hoist along a beam or track. They consist of a robust structure that houses wheels or rollers, allowing the hoist to slide smoothly along the beam. The trolleys can be manual, driven via a chain, or motorised, for more precise and less tiring control.

Use of hoist trolleys in machine shops

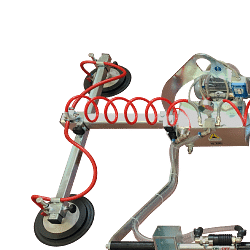

In machine shops, hoist trolleys are used to lift and move heavy loads safely and efficiently. They are particularly useful in environments where space is limited and material handling must be carried out with precision. The trolleys allow the hoists to be positioned exactly where needed, reducing the time and effort required for lifting and transporting materials.

Advantages of hoist trolleys

There are several advantages to using hoist trolleys. First of all, they improve safety at work, reducing the risk of accidents related to manual handling of loads. They also increase operational efficiency, allowing materials to be moved quickly and accurately around the workshop. Motorised trucks, in particular, offer superior control and reduce physical fatigue for operators, contributing to a more ergonomic working environment.

Types of traversing trolleys for hoists

There are different types of hoist trolleys, each designed for specific operational needs. Manual trolleys are ideal for light applications and where the frequency of use is low. Motorised trolleys, on the other hand, are more suitable for heavy industrial applications where frequent and precise handling is required. In addition, trucks can be designed to accommodate different beam widths and load capacities, offering a customised solution for every need.

Frequently asked questions about hoist trolleys

1. What is the load capacity of a hoist trolley?

The load capacity varies depending on the model and manufacturer. It is essential to choose a trolley that can support the maximum weight of the intended load, taking into account any overloading.

2. How is a hoist trolley installed?

The installation of a travelling trolley requires specific technical skills. It is advisable to use qualified personnel to ensure correct and safe installation.

3. What maintenance is required for a travelling trolley?

Regular maintenance is essential to ensure the correct functioning and safety of the carriage. This includes lubricating the moving parts, checking the wheels for wear and tear, and checking the structure for damage.

4. Is it possible to automate a manual trolley?

In some cases, it is possible to upgrade a manual trolley to a motorised one, but this depends on the specific model and operating conditions. It is advisable to consult the manufacturer to assess the options available.

5. What are the safety regulations for the use of traversing trolleys?

The use of forklift trucks is subject to specific safety regulations, which vary by country and industry sector. It is important to be aware of local regulations and ensure that all operations are compliant.

Conclusions

Hoist trolleys are indispensable tools in machine shops and industries that require efficient load handling solutions. They offer numerous advantages in terms of safety, efficiency and ergonomics, making them an ideal choice for improving production processes. With proper selection, installation and maintenance, transfer trucks can contribute significantly to a company's operational success.

Read More Read LessWhat are hoist trolleys?

Hoist trolleys are mechanical devices designed to enable the horizontal movement of a hoist along a beam or track. They consist of a robust structure that houses wheels or rollers, allowing the hoist to slide smoothly along the beam. The trolleys can be manual, driven via a chain, or motorised, for more precise and less tiring control.

Use of hoist trolleys in machine shops

In machine shops, hoist trolleys are used to lift and move heavy loads safely and efficiently. They are particularly useful in environments where space is limited and material handling must be carried out with precision. The trolleys allow the hoists to be positioned exactly where needed, reducing the time and effort required for lifting and transporting materials.

Advantages of hoist trolleys

There are several advantages to using hoist trolleys. First of all, they improve safety at work, reducing the risk of accidents related to manual handling of loads. They also increase operational efficiency, allowing materials to be moved quickly and accurately around the workshop. Motorised trucks, in particular, offer superior control and reduce physical fatigue for operators, contributing to a more ergonomic working environment.

Types of traversing trolleys for hoists

There are different types of hoist trolleys, each designed for specific operational needs. Manual trolleys are ideal for light applications and where the frequency of use is low. Motorised trolleys, on the other hand, are more suitable for heavy industrial applications where frequent and precise handling is required. In addition, trucks can be designed to accommodate different beam widths and load capacities, offering a customised solution for every need.

Frequently asked questions about hoist trolleys

1. What is the load capacity of a hoist trolley?

The load capacity varies depending on the model and manufacturer. It is essential to choose a trolley that can support the maximum weight of the intended load, taking into account any overloading.

2. How is a hoist trolley installed?

The installation of a travelling trolley requires specific technical skills. It is advisable to use qualified personnel to ensure correct and safe installation.

3. What maintenance is required for a travelling trolley?

Regular maintenance is essential to ensure the correct functioning and safety of the carriage. This includes lubricating the moving parts, checking the wheels for wear and tear, and checking the structure for damage.

4. Is it possible to automate a manual trolley?

In some cases, it is possible to upgrade a manual trolley to a motorised one, but this depends on the specific model and operating conditions. It is advisable to consult the manufacturer to assess the options available.

5. What are the safety regulations for the use of traversing trolleys?

The use of forklift trucks is subject to specific safety regulations, which vary by country and industry sector. It is important to be aware of local regulations and ensure that all operations are compliant.

Conclusions

Hoist trolleys are indispensable tools in machine shops and industries that require efficient load handling solutions. They offer numerous advantages in terms of safety, efficiency and ergonomics, making them an ideal choice for improving production processes. With proper selection, installation and maintenance, transfer trucks can contribute significantly to a company's operational success.