Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

02.927371

- Supporting big orders

02.38298620

-

info@linkindustrialtools.it

- Request assistance with form

Or contact us with the chat in the lower right corner

< Clamping systems

- Home

- Clamping systems

- Zero-point clamping systems

Zero-point clamping systems

Zero point cnc clamping systems: innovation and precision for machine shops

In the world of machine shops, efficiency and precision are key elements in guaranteeing the quality of the end product and competitiveness on the market. Zero point cnc clamping systems represent one of the most advanced and innovative solutions for optimising production processes, reducing setup times and improving machining precision. In this in-depth look, we will explore in detail what these systems are, how they work, their advantages and practical applications in machine shops.

Understanding zero point cnc clamping systems

Zero point cnc clamping systems are clamping devices that allow workpieces to be quickly clamped and unclamped on machine tools. These systems use a centralised clamping mechanism that allows workpieces to be positioned with extreme precision and repeatability. The term 'zero point' refers to the fixed reference point that is used to ensure that each workpiece is positioned in exactly the same way, regardless of the number of times it is assembled and disassembled.

Function and main components

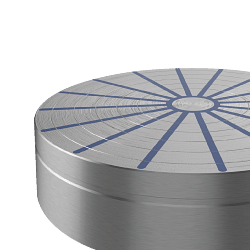

The heart of a cnc zero point clamping system is a series of clamping modules that are mounted on the machine tool table. These modules are equipped with clamping pins that fit into special slots on the workpiece clamping devices. When the system is activated, the pins are locked in position, ensuring secure and precise clamping. The workpiece is released just as quickly, allowing setup times to be significantly reduced.

Advantages of zero-point cnc clamping systems

The adoption of cnc zero-point clamping systems offers several advantages to machine shops. Firstly, the reduction in setup time allows for increased productivity, as machine tools can be retooled in a much shorter time compared to traditional methods. In addition, the accuracy and repeatability of part positioning improves the quality of machining, reducing the risk of errors and rejects.

Another significant advantage is operational flexibility. Zero point cnc clamping systems allow rapid switching between machining operations, facilitating the management of small production batches and the customisation of products. This is particularly important in a market context where the demand for customised products is constantly growing.

Practical applications in machine shops

Zero point cnc clamping systems find application in a wide range of industries, from precision machining to the production of components for the automotive and aerospace industries. In machine shops, these systems are used for clamping workpieces of different sizes and shapes, ensuring a high degree of operational versatility.

A practical application example is the machining of complex components that require several milling and drilling operations. Thanks to zero point cnc clamping systems, it is possible to perform all operations without having to manually reposition the part, thus reducing the risk of alignment errors and improving the quality of the final product.

Answers to frequently asked questions

Many people in the industry ask questions about zero point cnc clamping systems, particularly regarding their implementation and maintenance. One of the most common questions concerns the compatibility of these systems with existing machine tools. Fortunately, zero point cnc clamping systems are designed to be easily integrated with most machine tools, thanks to the availability of specific adapters and accessories.

Another frequent question concerns the maintenance of zero point cnc clamping systems. These systems are generally designed to be robust and reliable, requiring minimal maintenance. However, it is important to follow the manufacturer's recommendations to ensure optimal operation and prolong the life of the system.

Conclusions

Zero point cnc clamping systems represent an advanced and innovative solution for machine shops wishing to improve the efficiency and precision of their machining operations. With reduced setup times, positioning accuracy and operational flexibility, these systems offer a significant competitive advantage in an increasingly demanding market. The adoption of zero point cnc clamping systems can radically transform production processes, enabling machine shops to effectively meet the challenges of the modern market.

Read More Read LessIn the world of machine shops, efficiency and precision are key elements in guaranteeing the quality of the end product and competitiveness on the market. Zero point cnc clamping systems represent one of the most advanced and innovative solutions for optimising production processes, reducing setup times and improving machining precision. In this in-depth look, we will explore in detail what these systems are, how they work, their advantages and practical applications in machine shops.

Understanding zero point cnc clamping systems

Zero point cnc clamping systems are clamping devices that allow workpieces to be quickly clamped and unclamped on machine tools. These systems use a centralised clamping mechanism that allows workpieces to be positioned with extreme precision and repeatability. The term 'zero point' refers to the fixed reference point that is used to ensure that each workpiece is positioned in exactly the same way, regardless of the number of times it is assembled and disassembled.

Function and main components

The heart of a cnc zero point clamping system is a series of clamping modules that are mounted on the machine tool table. These modules are equipped with clamping pins that fit into special slots on the workpiece clamping devices. When the system is activated, the pins are locked in position, ensuring secure and precise clamping. The workpiece is released just as quickly, allowing setup times to be significantly reduced.

Advantages of zero-point cnc clamping systems

The adoption of cnc zero-point clamping systems offers several advantages to machine shops. Firstly, the reduction in setup time allows for increased productivity, as machine tools can be retooled in a much shorter time compared to traditional methods. In addition, the accuracy and repeatability of part positioning improves the quality of machining, reducing the risk of errors and rejects.

Another significant advantage is operational flexibility. Zero point cnc clamping systems allow rapid switching between machining operations, facilitating the management of small production batches and the customisation of products. This is particularly important in a market context where the demand for customised products is constantly growing.

Practical applications in machine shops

Zero point cnc clamping systems find application in a wide range of industries, from precision machining to the production of components for the automotive and aerospace industries. In machine shops, these systems are used for clamping workpieces of different sizes and shapes, ensuring a high degree of operational versatility.

A practical application example is the machining of complex components that require several milling and drilling operations. Thanks to zero point cnc clamping systems, it is possible to perform all operations without having to manually reposition the part, thus reducing the risk of alignment errors and improving the quality of the final product.

Answers to frequently asked questions

Many people in the industry ask questions about zero point cnc clamping systems, particularly regarding their implementation and maintenance. One of the most common questions concerns the compatibility of these systems with existing machine tools. Fortunately, zero point cnc clamping systems are designed to be easily integrated with most machine tools, thanks to the availability of specific adapters and accessories.

Another frequent question concerns the maintenance of zero point cnc clamping systems. These systems are generally designed to be robust and reliable, requiring minimal maintenance. However, it is important to follow the manufacturer's recommendations to ensure optimal operation and prolong the life of the system.

Conclusions

Zero point cnc clamping systems represent an advanced and innovative solution for machine shops wishing to improve the efficiency and precision of their machining operations. With reduced setup times, positioning accuracy and operational flexibility, these systems offer a significant competitive advantage in an increasingly demanding market. The adoption of zero point cnc clamping systems can radically transform production processes, enabling machine shops to effectively meet the challenges of the modern market.