Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

02.927371

- Supporting big orders

02.38298620

-

info@linkindustrialtools.it

- Request assistance with form

Or contact us with the chat in the lower right corner

- Home

- Clamping systems

- Spring collects for locking and chucks

Spring collects for locking and chucks

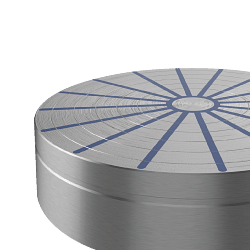

SCHÜSSLER: Precision Chucks for Mechanical Machining

SCHÜSSLER is a brand specialising in the production of precision chucks for machine tools. With a focus on quality, reliability and technological innovation, SCHÜSSLER products guarantee high performance for tool clamping in sectors such as the mechanical, aerospace and automotive industries.

Why choose SCHÜSSLER chucks?

- Precision and Stability – Safe and repeatable clamping for high quality machining.

- Reliability and Durability – Resistant materials and advanced treatments for a long operating life.

- Technological Innovation – Design studied to reduce vibrations and guarantee maximum control of the piece.

- Wide Range of Products – Spindles for milling, turning, drilling and grinding.

- Universal Compatibility – Solutions suitable for different machine tools and applications.

SCHÜSSLER Product Range

1. Milling Spindles

Designed to ensure secure clamping and reduce vibration during high-speed machining.

- ER collet chucks – High precision for precision milling and general machining.

- HSK chucks – Rigid connection for high speed milling machines with high stability.

- BT and SK chucks – Perfect for CNC machining centre applications.

2. Chucks for turning

Clamping tools designed to ensure precision and rigidity in turning operations.

- Self-centring chucks – Ideal for workpieces of varying dimensions with uniform clamping.

- Hydraulic chucks – Guarantee high clamping force and reduced vibration.

- Elastic expansion chucks – Perfect for machining operations that require high concentricity.

3. Drilling and Grinding Chucks

Optimised to guarantee maximum precision and stability in drilling and grinding operations.

- Rack and pinion chucks – Ideal for deep drilling and high performance.

- Quick-clamping chucks – Fast tool change to improve operational efficiency.

- Precision grinding chucks – Designed for machining with tight tolerances.

4. Accessories and spare parts for chucks

A wide range of support components to optimise spindle performance.

- Collet chucks – Available in different sizes to suit every need.

- Collet wrenches – Ergonomic tools for quick and safe tool changes.

- Anti-vibration elements – Reduction of oscillations for more precise machining.

Industrial Applications

SCHÜSSLER spindles are used in various industrial sectors:

- Mechanical Industry – For precision machining on steels, alloys and advanced materials.

- Aerospace – For the production of highly complex components with tight tolerances.

- Automotive – For milling, turning and drilling of mechanical parts and engine components.

- Energy sector – For machining materials used in turbines and industrial plants.

- Moulding and mould production – For high-precision machining in complex production environments.

Conclusion

Choosing SCHÜSSLER means relying on a brand specialised in precision clamping technology. With a complete range of chucks for milling, turning, drilling and grinding, SCHÜSSLER guarantees reliability, durability and maximum precision, meeting the needs of the most advanced industries.

Kerfolg: High Precision Cutting Tools for Mechanical Processing

Kerfolg is a premium brand dedicated to enhancing performance and precision in machining, with the aim of maximising its customers' productivity. Central to Kerfolg's philosophy is the optimisation of production processes, adopting a customer-centric approach to listen and satisfy the specific needs of each customer.

Why choose Kerfolg products?

- Advanced Technology: Kerfolg tools are designed with precise geometries and made with selected materials and coatings, guaranteeing maximum productivity in every type of machining.

- Wide Range of Products: Kerfolg offers a vast selection of tools, from integral tools to mechanical clamping tools, up to clamping systems, covering all the needs of mechanical workshops.

- Focus on the Customer: The company's activities are centred on listening to and satisfying the needs of its customers, offering customised solutions to optimise production processes.

- Continuous Development: A dedicated team of project managers works constantly to innovate and improve products, ensuring cutting-edge technologies and superior performance.

Kerfolg Product Range

1. Integral Tools

Designed to guarantee precision and durability, Kerfolg integral tools include:

- HSS and Hard Metal Drills: Ideal for drilling operations on different materials, they ensure high performance and long life.

- Threading Taps: Essential tools for creating precise threads, available in various sizes and types to suit different applications.

- HSS and Carbide Cutters: Offer effective solutions for milling operations, guaranteeing high quality finishes and reduced processing times.

2. Indexable Tools

Designed to offer flexibility and efficiency, Kerfolg indexable tools include:

- Inserts and Insert Holders: Available in different geometries and materials, they allow high-precision turning and milling operations.

- Parting and High-Feed Cutters: Ideal for fast and precise cutting operations, they optimise production times and reduce tool wear.

- Knurling tools: Specific tools for creating knurls on mechanical components, ensuring uniform and high-quality results.

3. Clamping Systems

To guarantee stability and precision during machining, Kerfolg offers:

- Chucks: Designed to ensure safe and precise tool clamping, available in different types to adapt to various machine tools.

- Presetting machines: Advanced tools for measuring and adjusting tools, helping to reduce setup times and increase production efficiency.

Industrial Applications

Kerfolg products are used in a wide range of industrial sectors, including:

- Mechanical Industry: Solutions for precision machining of metal and non-metal components.

- Aerospace sector: tools designed to meet the high standards of quality and precision required in the aeronautics industry.

- Automotive industry: tools for the production and maintenance of automotive components, guaranteeing efficiency and reliability.

- Mould production: specific tools for the production of moulds with high quality finishes and tight tolerances.

Conclusion

Choosing Kerfolg means relying on a partner dedicated to excellence in machining, capable of offering high quality products and customised solutions to optimise productivity. With a constant commitment to innovation and customer satisfaction, Kerfolg is the ideal choice for companies looking for reliable and high-performance cutting tools.