Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

02.927371

- Supporting big orders

02.38298620

-

info@linkindustrialtools.it

- Request assistance with form

Or contact us with the chat in the lower right corner

- Home

- Clamping systems

- Spring collects for locking and chucks

Spring collects for locking and chucks

WRK is a brand that offers a complete range of professional hand tools designed for workshops, construction sites and maintenance workers. The brand's philosophy is to offer robust, practical and affordable tools that guarantee reliability even in intensive working environments.

WRK Product Range

- Screwdrivers and wrenchesPractical and durable solutions for secure and precise tightening.

- Pliers, cutters and tongsReliable tools for gripping, cutting and mechanical work.

- Hammers and striking toolsMade from durable materials to withstand intensive use.

- Assorted tool setsComplete cases and kits for professionals and maintenance workers.

- Various accessories and toolsA range of versatile tools for everyday tasks in the workshop and on the construction site.

Why choose WRK on Link Industrial Tools

- Resistance: robust tools for heavy-duty use.

- Versatility: complete range for different applications.

- Affordability: excellent value for money.

- Reliability: tools designed to last.

- Practicality: solutions designed for professionals and maintenance workers.

Typical applications

- Mechanical workshops and production departments

- Construction and industrial sites

- Routine and extraordinary maintenance

- Automotive and transport sector

- Professional DIY

FAQs about WRK

1. Does WRK only produce screwdrivers and wrenches?

No, the range also includes pliers, hammers, wire cutters and tool sets.

2. Are WRK tools suitable for intensive professional use?

Yes, they are designed to withstand even the toughest conditions in workshops and construction sites.

3. Does WRK offer assorted tool kits?

Yes, cases and complete sets are available for different needs.

4. Is it a brand that is also suitable for advanced DIY?

Yes, WRK products are suitable for both professionals and enthusiasts.

5. Where are WRK tools most commonly used?

In workshops, construction sites, automotive, maintenance and precision work.

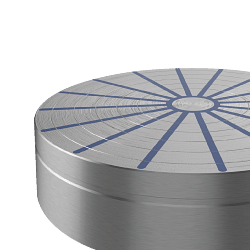

ETM is a brand specialising in the production of precision spring collets and robust clamping systems for mechanical machining. Ideal for milling, drilling, turning and CNC applications, they guarantee stability, low vibration and quick tool changes.

Product Range

- ER Spring ColletsAvailable in the ER11, ER16, ER20, ER25 and ER32 series. They offer precise and uniform clamping, with a tolerance of ±0.5 mm, ideal for milling, drilling and threading tools.

- DIN 6499/ER SpindlesThey allow the secure clamping of cylindrical tools. Guaranteed for high concentricity and compatibility on CNC systems and machine tools.

- Shrink-Fit ColletsThermal fitting system that ensures perfect concentricity, high rigidity and extended tool life. Ideal for high-speed machining.

- Weldon ColletsDesigned for heavy-duty milling applications: enhanced clamping thanks to the Weldon surface and robust tool holders.

- Tapping collets With axial compensation, they guarantee thread precision and reduce the risk of tap breakage.

Typical applications

- High-precision machining operations: milling, drilling, turning.

- Mould and aerospace component production.

- High-tolerance applications in the automotive sector.

- Production of special alloys and critical components.

Why choose ETM on Link Industrial Tools

- Complete range in stock: ER, Shrink-Fit, Weldon, tapping.

- High quality and long life thanks to selected materials.

- Quick tool change for maximum efficiency.

- Universal compatibility with major CNC machines.

FAQs about ETM

1. What types of collets does ETM produce?

ER spring collets (ER11–ER32), Shrink-Fit, Weldon and tapping collets with axial compensation.

2. What is a Shrink-Fit collet used for?

It ensures maximum concentricity, rigidity in high-speed machining and reduced wear.

3. What are the advantages of a Weldon collet?

It is suitable for heavy milling thanks to the solid clamping of the tool, ideal in harsh working environments.

4. How do ETM tapping chucks work?

They use axial compensation to ensure perfect threads and protect the tap from breakage.

5. For which field is ETM recommended?

For mechanical workshops, automotive, aerospace, moulds, high-precision components.

Schüssler is a brand specialising in the production of precision chucks for drills, lathes and machine tools. With a complete range that includes self-centring, keyed and self-locking chucks, Schüssler stands out for its attention to precision, robustness and durability, offering reliable solutions for professionals and mechanical workshops.

Schüssler Chuck Range

- Self-centring chucksFor lathes and machine tools, with precision collets that guarantee stability and perfect centring.

- Keyed chucksTraditional solutions for drill presses and machine tools, safe and resistant.

- Self-locking chucksIdeal for manual and electric drills, they allow quick, keyless clamping.

- Precision chucksHigh-accuracy models for machining delicate workpieces with tight tolerances.

- Accessories and spare partsJaws, keys and components to keep your chucks running efficiently.

Why choose Schüssler on Link Industrial Tools

- Guaranteed precision: reliable centring for accurate machining.

- Complete range: from manual chucks to industrial self-centring chucks.

- Robustness and durability: quality materials resistant to wear and mechanical stress.

- Versatility: compatible with various machine tools and drills.

- Technical support: advice on choosing the most suitable chuck.

Typical applications

- Mechanical workshops and turning shops

- Machining centres and CNC machines

- Column and bench drills

- Precision machining and prototyping

- Industrial production and maintenance

FAQs about Schüssler

1. What is the difference between a keyed chuck and a self-tightening chuck?

The keyed chuck ensures traditional, robust clamping, while the self-tightening chuck allows for quick bit changes without tools.

2. Are Schüssler chucks compatible with CNC machines?

Yes, the range includes models for CNC lathes and machining centres.

3. Are Schüssler chuck jaws interchangeable?

Yes, original spare parts are available to ensure maximum efficiency at all times.

4. Are keyless chucks also suitable for professional use?

Yes, they offer precision and robustness, as well as great ease of use.

5. Where are Schüssler chucks mainly used?

In mechanical workshops, turning shops, CNC machining centres and in the industrial sector.