Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

02.927371

- Supporting big orders

02.38298620

-

info@linkindustrialtools.it

- Request assistance with form

Or contact us with the chat in the lower right corner

- Home

- Clamping systems

- Self centering chucks

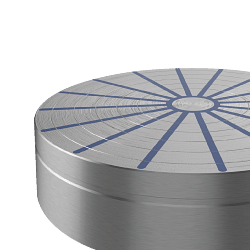

Self centering chucks

Wessel: Clamping Solutions for Maximum Precision

Wessel is a brand specialising in the production of self-centring chucks, steady rests and clamping systems designed to guarantee reliability, precision and durability in mechanical machining. Thanks to a wide range of products and the possibility of creating tailor-made solutions, Wessel is the ideal partner for companies operating in the turning and milling sector.

Why choose Wessel products?

- Reliability and Strength – Devices made with high quality materials for safe and long-lasting clamping.

- Maximum Precision – Advanced technologies to guarantee machining with reduced tolerances.

- Wide Range of Solutions – Chucks, steady rests and accessories suitable for different production needs.

- Customisation – Possibility to develop customised products for specific applications.

- Process Efficiency – Solutions designed to optimise productivity and reduce machining times.

Wessel Product Range

1. Double Guide Self-Centring Chucks

Essential turning tools, guaranteeing precise and uniform clamping.

- Standard versions – Available in different sizes to adapt to any type of machining.

- Special models – Made on request for customised applications.

- High gripping force – For a stable and secure hold even at high speeds.

2. Self-centring steady rests

Essential supports for machining long or delicate pieces.

- Standard steady rests – For support during turning and milling operations.

- Customised steady rests – Tailor-made for workpieces of particular sizes and shapes.

- Automatic adjustment system – For perfect and stable centring.

3. Special clamping systems

Advanced solutions for specific needs.

- Customised devices – Developed according to customer requirements.

- Robust and reliable structures – To guarantee maximum operational safety.

- Compatibility with industrial machinery – Easy to integrate into existing production systems.

Industrial Applications

Wessel products are used in various industrial sectors, including:

- Mechanical Machining – Chucks and steady rests for high precision turning and milling operations.

- Automotive industry – clamping tools for the production of engine components and structural parts.

- Aerospace and Defence – reliable clamping solutions for machining advanced materials.

- Industrial machinery – devices for the production of mechanical equipment and systems.

Conclusion

Choosing Wessel means relying on a brand that is synonymous with precision, quality and innovation in the field of clamping devices. Thanks to the combination of standard products and customised solutions, Wessel offers essential tools to improve the efficiency and safety of mechanical machining.

RÖHM: Advanced Solutions for Clamping Technology

RÖHM is a leading manufacturer of clamping and locking systems for machine tools, offering precision solutions for the mechanical, manufacturing and aerospace industries. With over a century of experience, RÖHM develops reliable technologies that improve productivity and guarantee excellent machining quality.

Why choose RÖHM products?

- Precision and Reliability – Tools designed to guarantee secure clamping, reducing errors and vibrations during machining.

- Technological Innovation – Cutting-edge solutions to improve the efficiency of production processes.

- Durability and Strength – High quality materials and advanced treatments for a long operating life.

- Wide Range of Products – Chucks, vices, CNC clamping systems and accessories for every industrial need.

- Versatility of Use – Suitable for sectors such as automotive, aerospace, mechanical engineering and energy.

RÖHM Product Range

1. Drill and CNC Chucks

Solutions for the precise clamping of tools and workpieces on machine tools and machining centres.

- Self-centring chucks – High precision for industrial applications and machining.

- Quick-clamping chucks – Fast tool change without keys, for greater efficiency.

- Collet chucks – Ideal for high-speed CNC milling and drilling.

2. Machine Tool Vices

Reliable clamping systems to hold workpieces securely during machining.

- Precision Vices – Ensure high stability in milling and grinding operations.

- Hydraulic and Pneumatic Vices – Powerful and secure clamping for heavy machining.

- Modular Vices – Perfect for machining centres and large-scale production.

3. CNC Clamping Systems

Advanced technologies for automation and improved production efficiency.

- CNC self-centring chucks – High precision for repeatable and secure clamping.

- Zero Point Systems – Quick tool change, reducing set-up times.

- Quick clamping systems – To increase productivity by reducing machine downtime.

4. Grippers for Robotics

Tools for industrial automation and collaborative robots.

- Precision grippers – Perfect for the automotive and aerospace sectors.

- Automatic clamping systems – Designed for highly efficient robotic operations.

Industrial Applications

RÖHM products are used in a wide range of sectors:

- Mechanical Engineering – For milling, turning and precision grinding.

- Automotive – Secure clamping of components for vehicle production.

- Aerospace – High precision for machining light and resistant materials.

- Energy and Oil & Gas – Solutions for machining large industrial components.

- Railway – Production and maintenance of components for the transport sector.

Conclusion

Choosing RÖHM means relying on a brand that is synonymous with quality, innovation and reliability in clamping technology. With a wide range of chucks, vices, CNC clamping systems and grippers, RÖHM offers tailor-made solutions to improve efficiency and precision in every industrial application.