< Solid cutting tools Thread milling cutters

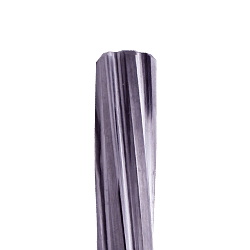

Tungsten carbide thread milling cutters are an essential tool for machine shops that strive for precision and efficiency in thread making. Thanks to their advanced composition and design, these tools offer a number of advantages that make them indispensable for those working in the metalworking industry. In this in-depth look, we will explore in detail what carbide thread milling cutters are, how they are used, the benefits they offer and answer some of the most frequently asked questions on this topic.

Understanding carbide thread milling cutters

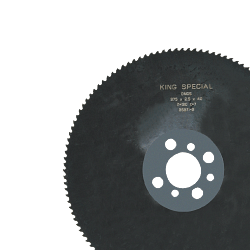

Carbide thread milling cutters are tools designed to create precise threads on a variety of materials, including steel, aluminium and special alloys. Tungsten carbide, also known as cemented carbide, is a material composed of tungsten carbide particles bonded together by a metal binder, usually cobalt. This gives the cutters superior hardness and wear resistance compared to high-speed steel tools, making them ideal for applications requiring high precision and durability.

The importance of precision in threading

Thread accuracy is crucial to ensure the structural integrity and functionality of mechanical components. A poorly manufactured thread can compromise the assembly and sealing of parts, leading to premature failure or operational inefficiency. Carbide thread milling cutters are designed to ensure tight tolerances and high-quality surfaces, minimising the risk of errors and improving the overall quality of the finished product.

Advantages of carbide thread milling cutters

One of the main advantages of carbide thread milling cutters is their ability to maintain a sharp edge even after numerous machining cycles. This translates into longer tool life and reduced downtime for tool changes. In addition, the carbide's heat resistance allows it to operate at higher cutting speeds, increasing productivity without compromising thread quality.

Applications of carbide thread milling cutters

Carbide thread milling cutters find applications in a wide range of industries, including automotive, aerospace, and industrial machinery manufacturing. They are particularly popular for machining difficult-to-cut materials, such as titanium alloys and stainless steels, where precision and tool life are critical.

Correct use of carbide thread milling cutters

To achieve the best results with carbide thread milling cutters, it is essential to follow certain operational guidelines. First of all, it is important to select the right cutter for the desired material and thread type. In addition, it is crucial to set the cutting parameters, such as speed and feed rate, correctly to avoid premature tool wear and ensure a high-quality finish. The use of appropriate lubricants can also help improve tool life and thread quality.

Frequently asked questions about carbide thread milling cutters

1. What is the difference between carbide and high-speed steel thread milling cutters?

Tungsten carbide thread milling cutters offer greater hardness and wear resistance than those made of high-speed steel, making them more suitable for high-speed applications and difficult-to-machine materials.

2. How do I choose the right thread milling cutter for a specific application?

The choice depends on the material to be machined, the type of thread required and the specifications of the machine tool. It is advisable to consult the manufacturer's reference tables to select the most suitable tool.

3. What are the signs of wear on a carbide thread milling cutter?

Common signs of wear include a reduction in thread quality, increased vibration during machining and a change in the cutting sound. It is important to monitor the tool regularly to avoid damage to the workpiece.

4. Can carbide thread milling cutters be reground?

Yes, carbide thread milling cutters can be reground, but it is a process that requires specialised equipment and technical expertise. It is often more cost-effective to replace the tool once it has reached the limit of its service life.

5. What are the best practices for maintenance of carbide threading cutters?

Regular maintenance includes cleaning the tool after each use, checking cutting conditions and using appropriate lubricants. Storing cutters in a dry, dust-free environment can also help extend their service life.

Conclusion

Tungsten carbide thread milling cutters are indispensable tools for machine shops that aim to achieve precise, high-quality threads. Due to their strength and durability, they offer significant advantages in terms of efficiency and productivity. Understanding their characteristics and proper use is crucial to exploiting their full potential and ensuring optimal results in every application.

Read More Read Less