< Solid cutting tools Taps for threading

Professional thread taps: a complete guide for machine shops

In the world of machine shops, the importance of high-quality tools cannot be underestimated. Among these, professional thread taps occupy a prominent place. These tools are essential for creating precise and reliable internal threads, a task that requires precision and expertise. In this article, we will explore in detail what thread taps are, how they are used, the advantages of using them, and answer some of the most frequently asked questions on this topic.

What are thread taps?

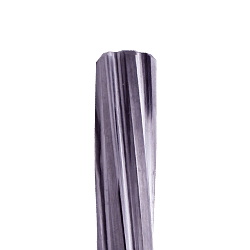

Thread taps are tools used to create internal threads in the holes of a workpiece. These tools are essential to ensure that screws and bolts can be screwed securely into mechanical components. Taps come in different shapes and sizes, each designed to suit specific threading requirements. Choosing the right tap depends on the workpiece material, the type of thread desired and the technical specifications of the project.

Types of thread taps

There are different types of thread taps, each with unique characteristics that make them suitable for specific applications. Among the most common are:

- Hand taps: mainly used for manual work, these taps are ideal for threading operations where precision is paramount. They are often used in combination with a thread turner to ensure optimal control during the threading process.

- Machine taps: Designed for use with machine tools, these taps are ideal for high-speed threading operations and mass production. They offer greater efficiency and precision than hand taps.

- Rolling taps: used to create threads without chip removal, these taps are ideal for ductile materials and offer greater thread strength.

How are thread taps used?

The correct use of thread taps is crucial for optimal results. Here is a step-by-step guide on how to use these tools:

1. Preparing the hole: before starting the threading process, it is essential to prepare the hole to the correct size. This ensures that the tap can enter easily and create an accurate thread.

2. Lubrication: applying a suitable lubricant to the tap and the hole helps reduce friction and prevent premature tool wear.

3. Inserting the tap: insert the tap into the hole and start rotating it slowly. It is important to keep the tap aligned with the axis of the hole to avoid crooked threads.

4. Advance and remove: advance the tap with smooth, controlled movements. Once the thread is complete, remove the tap carefully to avoid damaging the newly created thread.

Advantages of professional thread taps

The use of professional thread taps offers numerous advantages, including:

- Precision: high-quality taps guarantee precise and uniform threads, which are essential for the correct assembly of mechanical components.

- Durability: made of durable materials and designed to resist wear, professional taps offer a long service life.

- Efficiency: due to their advanced design, professional taps allow fast and efficient threading operations, reducing machining time.

- Versatility: available in a wide range of sizes and types, thread taps can be used for a variety of applications, from precision work to mass production.

Thread taps frequently asked questions

1. What is the difference between a hand-held tap and a machine tap?

Hand taps are designed for manual use and offer more control when threading, whereas machine taps are designed for use with machine tools and are ideal for high-speed operations.

2. How do I choose the right tap for my project?

Choosing the right tap depends on the workpiece material, the type of threading desired and the technical specifications of the project. It is important to consult the manufacturer's specifications and, if necessary, seek expert advice.

3. What are the most common materials used for thread taps?

Thread taps are generally made of high-speed steel (HSS) or tungsten carbide, materials known for their strength and durability.

4. How can I keep my thread taps in good condition?

To keep taps in good condition, it is important to clean them regularly, apply appropriate lubricants during use and store them in a dry, moisture-free environment.

5. Can a tap be used on hard materials such as stainless steel?

Yes, it is possible to use thread taps on hard materials such as stainless steel, but it is important to choose a tap specifically designed for these materials and to use appropriate lubricants to reduce friction.

In conclusion, professional thread taps are indispensable tools for machine shops that want to ensure precision and reliability in their assembly operations. With a thorough understanding of their characteristics and use, it is possible to optimise production processes and improve the quality of end products.

Read More Read Less