Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

02.927371

- Supporting big orders

02.38298620

-

info@linkindustrialtools.it

- Request assistance with form

Or contact us with the chat in the lower right corner

< Solid cutting tools

- Home

- Solid cutting tools

- Countersinks

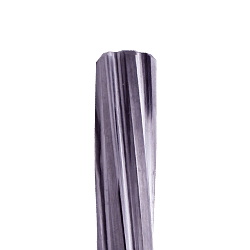

Countersinks

HSS and carbide metal countersinks are essential tools in modern machine shops. These tools, designed to perform countersinking operations on metal surfaces, are essential to guarantee precision and quality in machining processes. The choice between HSS (high-speed steel) and carbide depends on various factors, including the type of material to be machined, the machining speed and the desired tool life.

Understanding metal countersinks

Countersinks are tools used to create a countersink, i.e. a tapered hole, in a metal surface. This process is crucial to prepare holes for the insertion of screws or bolts, ensuring a perfect fit and superior aesthetic finish. HSS and carbide metal countersinks are particularly valued for their ability to work on hard and tough materials, delivering high quality results.

Countersink materials and construction

HSS countersinks are made of super high-speed steel, a material known for its wear resistance and ability to maintain a sharp edge even at high temperatures. This makes them ideal for high-speed machining on materials such as mild steel and aluminium. On the other hand, carbide countersinks, often made of tungsten carbide, offer superior durability and are particularly effective on extremely hard materials such as stainless steel and titanium alloys.

Advantages of using HSS and carbide countersinks

The use of HSS and carbide countersinks offers numerous advantages. Firstly, precision: these tools are designed to ensure uniform and precise countersinking, minimising the risk of errors. Also, durability: carbide countersinks, in particular, offer a significantly longer service life than conventional tools, reducing the need for frequent replacement. Finally, versatility: the ability to work on a wide range of materials makes these countersinks indispensable tools in any machine shop.

Correct use of metal countersinks

To achieve the best results, it is essential to use countersinks correctly. First of all, it is important to select the right tool according to the material to be machined. HSS countersinks are ideal for softer materials, while carbide countersinks are preferable for harder materials. In addition, it is essential to keep the tool sharp and in good condition to ensure accurate and uniform countersinking. Finally, it is advisable to use a suitable lubricant during the countersinking process to reduce friction and prolong tool life.

Frequently asked questions about metal countersinks

One of the most common questions concerns the difference between HSS and carbide countersinks. As mentioned, the choice depends mainly on the type of material to be machined and the desired tool life. Another frequently asked question concerns the maintenance of countersinks. It is important to clean the tools regularly and sharpen them when necessary to ensure optimal performance. Finally, many people ask what is the ideal rotation speed for countersinks. The speed depends on the material and the type of countersink used, but in general, it is advisable to start with a lower speed and increase it gradually to avoid overheating.

Conclusions

HSS and carbide metal countersinks are indispensable tools for any self-respecting machine shop. Their ability to guarantee precision, durability and versatility makes them an excellent choice for a wide range of applications. Whether working on mild steel or titanium alloys, these tools offer superior performance and high-quality results. Investing in high-quality countersinks is a wise decision for anyone wishing to improve the efficiency and quality of their metalworking operations.

Read More Read LessUnderstanding metal countersinks

Countersinks are tools used to create a countersink, i.e. a tapered hole, in a metal surface. This process is crucial to prepare holes for the insertion of screws or bolts, ensuring a perfect fit and superior aesthetic finish. HSS and carbide metal countersinks are particularly valued for their ability to work on hard and tough materials, delivering high quality results.

Countersink materials and construction

HSS countersinks are made of super high-speed steel, a material known for its wear resistance and ability to maintain a sharp edge even at high temperatures. This makes them ideal for high-speed machining on materials such as mild steel and aluminium. On the other hand, carbide countersinks, often made of tungsten carbide, offer superior durability and are particularly effective on extremely hard materials such as stainless steel and titanium alloys.

Advantages of using HSS and carbide countersinks

The use of HSS and carbide countersinks offers numerous advantages. Firstly, precision: these tools are designed to ensure uniform and precise countersinking, minimising the risk of errors. Also, durability: carbide countersinks, in particular, offer a significantly longer service life than conventional tools, reducing the need for frequent replacement. Finally, versatility: the ability to work on a wide range of materials makes these countersinks indispensable tools in any machine shop.

Correct use of metal countersinks

To achieve the best results, it is essential to use countersinks correctly. First of all, it is important to select the right tool according to the material to be machined. HSS countersinks are ideal for softer materials, while carbide countersinks are preferable for harder materials. In addition, it is essential to keep the tool sharp and in good condition to ensure accurate and uniform countersinking. Finally, it is advisable to use a suitable lubricant during the countersinking process to reduce friction and prolong tool life.

Frequently asked questions about metal countersinks

One of the most common questions concerns the difference between HSS and carbide countersinks. As mentioned, the choice depends mainly on the type of material to be machined and the desired tool life. Another frequently asked question concerns the maintenance of countersinks. It is important to clean the tools regularly and sharpen them when necessary to ensure optimal performance. Finally, many people ask what is the ideal rotation speed for countersinks. The speed depends on the material and the type of countersink used, but in general, it is advisable to start with a lower speed and increase it gradually to avoid overheating.

Conclusions

HSS and carbide metal countersinks are indispensable tools for any self-respecting machine shop. Their ability to guarantee precision, durability and versatility makes them an excellent choice for a wide range of applications. Whether working on mild steel or titanium alloys, these tools offer superior performance and high-quality results. Investing in high-quality countersinks is a wise decision for anyone wishing to improve the efficiency and quality of their metalworking operations.