< Solid cutting tools Circular saw blades

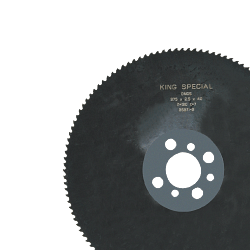

Circular saw blades for metal cutting are a crucial element in the landscape of mechanical workshops and manufacturing industries. These tools, if chosen and used correctly, can make all the difference in terms of efficiency, precision and quality of work performed. In this in-depth look, we will explore in detail the characteristics of circular saw blades, their use, the advantages they offer, and answer the most frequently asked questions in the industry.

Features of circular saw blades for metal cutting

Circular saw blades for metal cutting are designed to cope with hard, tough materials. These blades are generally made of high speed steel (HSS) or with tungsten carbide inserts, which are known for their hardness and wear resistance. The choice of material depends on the type of metal to be cut and the specific requirements of the application.

HSS blades are ideal for precision cuts on ferrous and non-ferrous metals, while blades with tungsten carbide inserts are preferred for applications that require greater durability and heat resistance. In addition, the design of the blade teeth plays a key role in the quality of the cut. Teeth can be designed for fast, coarse cuts or for slower, more precise cuts, depending on operational needs.

Use of circular saw blades in the industrial context

In machine shops, circular saw blades are used for a wide range of applications, from cutting pipes and metal bars to making precision components. Choosing the right blade is essential to optimise the cutting process and minimise material waste.

For best results, it is important to consider cutting speed, lubrication and cooling during the operation. The use of appropriate cutting fluids can significantly improve blade life and cut quality by reducing friction and heat generated during the process.

Advantages of circular saw blades for metal cutting

The use of circular saw blades offers numerous advantages in the industrial context. First of all, these saw blades enable precise and clean cuts, reducing the need for additional finishing work. This results in time and operating cost savings.

In addition, the high-quality blades are designed to last, reducing replacement frequency and associated costs. The ability to cut a wide range of metals, including stainless steels and special alloys, makes these blades extremely versatile and suitable for various industrial applications.

Frequently asked questions on the use of circular saw blades

1. What is the difference between HSS blades and blades with tungsten carbide inserts?

HSS saw blades are more economical and suitable for precision cuts on softer metals, whereas blades with tungsten carbide inserts offer longer life and are ideal for harder materials and high speed applications.

2. How can I extend the life of my circular saw blade?

To prolong the life of your blade, it is important to use appropriate cutting fluids, keep the blade sharp and adjust the cutting speed correctly according to the material being processed.

3. What are the signs that a blade needs to be replaced?

Common signs include increased resistance during cutting, uneven or burnt edges on the cut material and excessive noise during operation.

4. Can circular saw blades be resharpened?

Yes, many blades can be resharpened to prolong their service life. However, it is important to rely on professionals to ensure that the sharpening is done correctly and that the blade maintains its optimum performance.

5. What factors influence the choice of the right blade for a specific application?

Factors to consider include the type of metal to be cut, the thickness of the material, the desired cutting speed and the specifications of the machine used.

Conclusions

Circular saw blades for metal cutting are indispensable tools in machine shops and manufacturing industries. Choosing the right blade, combined with proper maintenance and use, can significantly improve operational efficiency and the quality of the end product. Investing in high quality blades and understanding their characteristics and applications is critical to achieving optimal results and maintaining a competitive edge in the industry.

Read More Read Less