Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

02.927371

- Supporting big orders

02.38298620

-

info@linkindustrialtools.it

- Request assistance with form

Or contact us with the chat in the lower right corner

< Pneumatics

- Home

- Pneumatics

- Blow guns and inflators

Blow guns and inflators

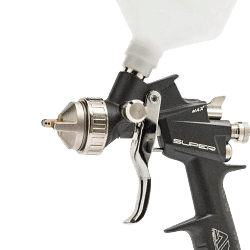

Blow guns and inflators are essential tools in the context of machine shops, where precision and efficiency are key requirements. Although these devices may seem simple in their design, they offer a range of applications that go far beyond their outward appearance. In this in-depth look, we explore the features, applications and benefits of blow guns and inflators, providing a comprehensive overview for those working in industry.

Features of blow and inflating guns

Blow and inflator guns are designed to provide precise control of air flow, which is essential for a variety of industrial applications. These tools are generally made of durable materials such as aluminium or polycarbonate, ensuring durability and resistance to wear. Blow guns are equipped with interchangeable nozzles that allow the pressure and direction of air flow to be adjusted, while inflation guns are often equipped with pressure gauges to monitor pressure during inflation.

Applications in machine shops

In machine shops, blow guns are mainly used for cleaning surfaces and components. The ability to remove dust, metal shavings and other debris without physical contact is critical to maintaining the integrity of mechanical components. Inflating guns, on the other hand, are essential for inflating tyres and other components that require specific air pressure. The precision offered by these tools ensures that tyres are inflated to the correct pressure, reducing the risk of irregular wear and improving fuel efficiency.

Benefits of using blowgun inflators

The adoption of blowgun and inflator guns in machine shops offers numerous advantages. Firstly, they improve operational efficiency by reducing the time needed for cleaning and inflating. Furthermore, the use of these tools reduces the risk of damage to delicate components, as the air flow can be precisely controlled. Another significant advantage is safety: blowing and inflating guns reduce the need for direct contact with potentially dangerous surfaces, minimising the risk of injury.

Frequently asked questions on the use of blow guns and inflators

One of the most common questions concerns the maintenance of these tools. It is essential to perform regular maintenance to ensure that the guns are working properly. This includes cleaning the nozzles and checking the tightness of the connections. Another frequent question concerns compatibility with different air compressors. It is important to ensure that the gun is compatible with the compressor used, in terms of pressure and air flow.

Innovations and future trends

The blowgun and inflator industry is constantly evolving, with innovations aimed at improving efficiency and safety. For example, some blow guns are now equipped with noise reduction systems, making them more suitable for noise-sensitive working environments. In addition, the integration of digital technologies, such as digital pressure gauges, is improving the accuracy and ease of use of blow guns.

In conclusion, blowgun and inflating guns are indispensable tools in machine shops, offering a combination of efficiency, precision and safety. Understanding their features and applications enables operators to fully exploit the advantages these tools offer, helping to improve productivity and the quality of work performed. As technologies continue to evolve, we can expect further improvements that will make these tools even more effective and versatile in the near future.

Read More Read LessFeatures of blow and inflating guns

Blow and inflator guns are designed to provide precise control of air flow, which is essential for a variety of industrial applications. These tools are generally made of durable materials such as aluminium or polycarbonate, ensuring durability and resistance to wear. Blow guns are equipped with interchangeable nozzles that allow the pressure and direction of air flow to be adjusted, while inflation guns are often equipped with pressure gauges to monitor pressure during inflation.

Applications in machine shops

In machine shops, blow guns are mainly used for cleaning surfaces and components. The ability to remove dust, metal shavings and other debris without physical contact is critical to maintaining the integrity of mechanical components. Inflating guns, on the other hand, are essential for inflating tyres and other components that require specific air pressure. The precision offered by these tools ensures that tyres are inflated to the correct pressure, reducing the risk of irregular wear and improving fuel efficiency.

Benefits of using blowgun inflators

The adoption of blowgun and inflator guns in machine shops offers numerous advantages. Firstly, they improve operational efficiency by reducing the time needed for cleaning and inflating. Furthermore, the use of these tools reduces the risk of damage to delicate components, as the air flow can be precisely controlled. Another significant advantage is safety: blowing and inflating guns reduce the need for direct contact with potentially dangerous surfaces, minimising the risk of injury.

Frequently asked questions on the use of blow guns and inflators

One of the most common questions concerns the maintenance of these tools. It is essential to perform regular maintenance to ensure that the guns are working properly. This includes cleaning the nozzles and checking the tightness of the connections. Another frequent question concerns compatibility with different air compressors. It is important to ensure that the gun is compatible with the compressor used, in terms of pressure and air flow.

Innovations and future trends

The blowgun and inflator industry is constantly evolving, with innovations aimed at improving efficiency and safety. For example, some blow guns are now equipped with noise reduction systems, making them more suitable for noise-sensitive working environments. In addition, the integration of digital technologies, such as digital pressure gauges, is improving the accuracy and ease of use of blow guns.

In conclusion, blowgun and inflating guns are indispensable tools in machine shops, offering a combination of efficiency, precision and safety. Understanding their features and applications enables operators to fully exploit the advantages these tools offer, helping to improve productivity and the quality of work performed. As technologies continue to evolve, we can expect further improvements that will make these tools even more effective and versatile in the near future.