Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

02.927371

- Supporting big orders

02.38298620

-

info@linkindustrialtools.it

- Request assistance with form

Or contact us with the chat in the lower right corner

< Pneumatics

- Home

- Pneumatics

- Airbrushes

Airbrushes

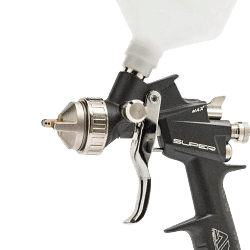

Professional compressed air spray guns are an essential tool for machine shops and anyone working in the paint and precision finishing industry. These devices, thanks to their ability to atomise colour into very fine particles, enable very high quality results with a precision and uniformity that other tools cannot guarantee. In this in-depth look, we will explore in detail what professional airbrushes are, how they work, their advantages and main applications, as well as answering frequently asked questions on this topic.

Introduction to professional compressed air guns

Compressed air guns are tools that use compressed air to spray paint or other liquid materials onto a surface. Their structure consists mainly of a liquid tank, a nozzle and an air control mechanism. The compressed air, passing through the nozzle, creates a negative pressure that draws the liquid from the tank, atomising it into a fine mist of particles. This process allows colour to be applied in a uniform and controlled manner, ideal for precision work.

Applications of airbrushes in machine shops

In machine shops, compressed air guns are used in a wide range of applications. They are used for painting automotive components, finishing metal parts and customising vehicles. The ability to apply thin, even layers of paint is critical to achieving a high-quality finish, minimising material waste and improving the efficiency of the production process.

Advantages of using professional airbrushes

The use of professional airbrushes offers numerous advantages. First of all, the precision in spraying allows for a uniform finish, reducing the need for retouching and improving the aesthetic appearance of the final product. In addition, the ability to adjust air pressure and paint flow allows the tool to be adapted to different needs, making it extremely versatile. Another significant advantage is the reduction of paint waste, as application is more controlled compared to traditional methods.

How to choose the right airbrush for your needs

Choosing the right airbrush depends on several factors, including the type of work to be done, the type of paint used and the level of precision required. It is important to consider the size of the nozzle, which affects the amount of paint sprayed and the finish obtained. Smaller nozzles are ideal for precision work, while larger nozzles are suitable for covering larger areas. In addition, reservoir capacity and air pressure are key elements to be assessed to ensure a constant and even flow of paint.

Maintenance and care of airbrushes

To ensure optimal performance and a long service life, regular maintenance of compressed air guns is essential. After each use, it is important to clean the nozzle and tank thoroughly to remove any paint residue. The use of specific solvents can help dissolve stubborn deposits. It is also advisable to periodically check the seals and moving parts to ensure they are in good condition and replace them if necessary.

Frequently asked questions about professional airbrushes

1. What is the difference between a gravity airbrush and a syphon airbrush?

Gravity airbrushes have the reservoir positioned above the nozzle, using gravity to feed the paint flow. Syphon airbrushes, on the other hand, have the reservoir below the nozzle and use air pressure to draw in the paint. Gravity airbrushes are generally preferred for precision work, while siphon airbrushes are suitable for applications that require more paint.

2. What types of paint can be used with compressed air guns?

Compressed air guns can be used with a wide range of paints, including acrylic, polyurethane, epoxy and water-based. It is important to choose the appropriate nozzle and air pressure according to the type of paint for best results.

3. How can I prevent the airbrush from clogging during use?

To avoid clogging, it is essential to dilute the paint correctly according to the manufacturer's instructions and to use filters to remove any impurities. In addition, cleaning the nozzle and tank regularly helps to prevent residue build-up.

4. What is the ideal air pressure for using an airbrush?

The ideal air pressure varies depending on the type of work and the paint used, but is generally between 15 and 30 psi. It is important to adjust the pressure according to your specific needs in order to achieve an even spray pattern.

5. Are airbrushes suitable for large-scale work?

Yes, compressed air guns can be used for large-scale work, but it is important to choose a model with a tank of adequate capacity and a compressor that can provide a constant air flow to avoid interruptions during application.

Conclusion

Professional compressed air guns are indispensable tools for those working in the paint and precision finishing industry. Their ability to apply paint in a uniform and controlled manner makes them ideal for a wide range of applications in machine shops. Choosing the right spray gun, regular maintenance and understanding the correct techniques of use are key to achieving excellent results and maximising the efficiency of the production process. With the right care and attention, airbrushes can deliver outstanding performance and contribute to the success of any painting project.

Read More Read LessIntroduction to professional compressed air guns

Compressed air guns are tools that use compressed air to spray paint or other liquid materials onto a surface. Their structure consists mainly of a liquid tank, a nozzle and an air control mechanism. The compressed air, passing through the nozzle, creates a negative pressure that draws the liquid from the tank, atomising it into a fine mist of particles. This process allows colour to be applied in a uniform and controlled manner, ideal for precision work.

Applications of airbrushes in machine shops

In machine shops, compressed air guns are used in a wide range of applications. They are used for painting automotive components, finishing metal parts and customising vehicles. The ability to apply thin, even layers of paint is critical to achieving a high-quality finish, minimising material waste and improving the efficiency of the production process.

Advantages of using professional airbrushes

The use of professional airbrushes offers numerous advantages. First of all, the precision in spraying allows for a uniform finish, reducing the need for retouching and improving the aesthetic appearance of the final product. In addition, the ability to adjust air pressure and paint flow allows the tool to be adapted to different needs, making it extremely versatile. Another significant advantage is the reduction of paint waste, as application is more controlled compared to traditional methods.

How to choose the right airbrush for your needs

Choosing the right airbrush depends on several factors, including the type of work to be done, the type of paint used and the level of precision required. It is important to consider the size of the nozzle, which affects the amount of paint sprayed and the finish obtained. Smaller nozzles are ideal for precision work, while larger nozzles are suitable for covering larger areas. In addition, reservoir capacity and air pressure are key elements to be assessed to ensure a constant and even flow of paint.

Maintenance and care of airbrushes

To ensure optimal performance and a long service life, regular maintenance of compressed air guns is essential. After each use, it is important to clean the nozzle and tank thoroughly to remove any paint residue. The use of specific solvents can help dissolve stubborn deposits. It is also advisable to periodically check the seals and moving parts to ensure they are in good condition and replace them if necessary.

Frequently asked questions about professional airbrushes

1. What is the difference between a gravity airbrush and a syphon airbrush?

Gravity airbrushes have the reservoir positioned above the nozzle, using gravity to feed the paint flow. Syphon airbrushes, on the other hand, have the reservoir below the nozzle and use air pressure to draw in the paint. Gravity airbrushes are generally preferred for precision work, while siphon airbrushes are suitable for applications that require more paint.

2. What types of paint can be used with compressed air guns?

Compressed air guns can be used with a wide range of paints, including acrylic, polyurethane, epoxy and water-based. It is important to choose the appropriate nozzle and air pressure according to the type of paint for best results.

3. How can I prevent the airbrush from clogging during use?

To avoid clogging, it is essential to dilute the paint correctly according to the manufacturer's instructions and to use filters to remove any impurities. In addition, cleaning the nozzle and tank regularly helps to prevent residue build-up.

4. What is the ideal air pressure for using an airbrush?

The ideal air pressure varies depending on the type of work and the paint used, but is generally between 15 and 30 psi. It is important to adjust the pressure according to your specific needs in order to achieve an even spray pattern.

5. Are airbrushes suitable for large-scale work?

Yes, compressed air guns can be used for large-scale work, but it is important to choose a model with a tank of adequate capacity and a compressor that can provide a constant air flow to avoid interruptions during application.

Conclusion

Professional compressed air guns are indispensable tools for those working in the paint and precision finishing industry. Their ability to apply paint in a uniform and controlled manner makes them ideal for a wide range of applications in machine shops. Choosing the right spray gun, regular maintenance and understanding the correct techniques of use are key to achieving excellent results and maximising the efficiency of the production process. With the right care and attention, airbrushes can deliver outstanding performance and contribute to the success of any painting project.