< Milling cutters Multifunctional milling cutters and round inserts

Multifunctional milling cutters and round inserts for CNC milling: a complete guide for machine shops

In the world of machine shops, efficiency and precision are key elements in guaranteeing the quality of the end product. Multifunctional milling cutters and round inserts for CNC milling are essential tools for achieving these goals. In this in-depth look, we will explore in detail what these tools are, how they are used, the advantages they offer and answer some of the most frequently asked questions.

Introduction to multifunctional milling cutters and round inserts

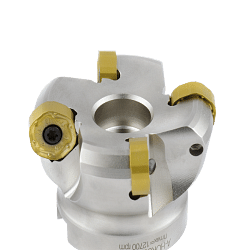

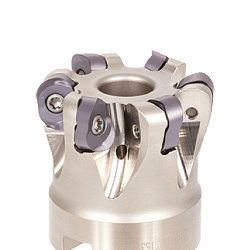

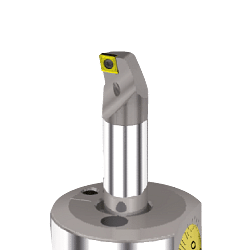

Multifunctional milling cutters are tools designed to perform a variety of milling operations, reducing the need to change tools during the machining process. This not only improves efficiency, but also reduces machine downtime, increasing overall productivity. Round inserts, on the other hand, are interchangeable components that fit on milling cutters and lathes, designed to offer greater durability and precision when machining materials.

Advantages of multifunctional milling cutters

One of the main advantages of multifunctional milling cutters is their versatility. These tools can be used for a wide range of operations, including milling, drilling and reaming. This reduces the need for a large inventory of different tools, simplifying tool management and reducing overall costs.

In addition, the multifunctional cutters are designed to offer longer tool life than conventional tools. Thanks to advanced materials and special coatings, these cutters can withstand extreme working conditions, reducing the frequency of replacement and maintenance.

The importance of round inserts in CNC milling

Round inserts are particularly valued for their ability to evenly distribute cutting forces, reducing wear and improving the surface finish of the machined part. This is especially important in CNC milling applications, where precision is crucial.

Another advantage of round inserts is their ease of replacement. When an insert wears out, it can be quickly replaced without having to remove the entire tool, reducing machine downtime and improving operational efficiency.

How to choose the right multifunctional cutters and round inserts

Choosing the right multifunctional cutters and round inserts depends on several factors, including the type of material to be machined, application specifications and production requirements. It is important to consider tool geometry, insert material and coating, as these elements directly influence tool performance and tool life.

For applications requiring a high quality surface finish, it is advisable to opt for inserts with an advanced coating that reduces friction and wear. In addition, choosing cutters with an optimised chip removal design can further improve the efficiency of the machining process.

Frequently asked questions about multifunctional cutters and round inserts

1. What are the most common materials used for multifunctional milling cutters?

Multifunctional cutters are often made of tungsten carbide, high-speed steel (HSS) or ceramic materials. Tungsten carbide is particularly valued for its hardness and wear resistance, while HSS offers good toughness and impact resistance.

2. How can I improve the tool life of round inserts?

To improve the tool life of round inserts, it is important to follow the manufacturer's recommendations in terms of cutting speed and feed rate. In addition, the use of appropriate lubricants can reduce friction and wear, prolonging the life of the inserts.

3. What are the typical applications of multifunctional milling cutters?

Multifunctional milling cutters are used in a wide range of applications, including the production of automotive, aerospace and industrial components. They are particularly useful in high volume production environments where reducing tool change times is critical.

4. Are round inserts suitable for all types of materials?

Round inserts are suitable for a wide range of materials, including steel, cast iron, aluminium and composite materials. However, it is important to choose the right insert for the specific material to ensure optimum performance.

5. What are the future trends in multifunctional milling cutters and round inserts?

Future trends include the development of advanced materials and coatings that further improve tool life and performance. In addition, the integration of digital technologies and sensors in CNC milling systems is opening up new possibilities for real-time monitoring and optimisation of machining processes.

Conclusion

Multifunctional milling cutters and round inserts for CNC milling are indispensable tools for modern machine shops. They offer a combination of versatility, efficiency and precision that is difficult to match with traditional tools. Choosing the right tools and using them correctly can make the difference between an efficient production process and one that is costly and inefficient. As technologies and materials continue to evolve, the opportunities to further improve milling operations are endless, making these tools a strategic choice for any machine shop aiming to remain competitive in the global market.

Read More Read Less