Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

02.927371

- Supporting big orders

02.38298620

-

info@linkindustrialtools.it

- Request assistance with form

Or contact us with the chat in the lower right corner

< Milling cutters

- Home

- Milling cutters

- End milling cutters and inserts

End milling cutters and inserts

CNC milling cutters and inserts: a complete guide for machine shops

In the world of machining, efficiency and precision are key elements in ensuring the quality of the end product. CNC face milling cutters and inserts are essential tools for machine shops wishing to optimise production processes and achieve perfectly machined surfaces. In this article, we will explore in detail what CNC face milling cutters and inserts are, what they are used for, how they are used and what advantages they offer. In addition, we will answer frequently asked questions to provide a comprehensive and detailed overview.

Introduction to CNC face milling cutters and inserts

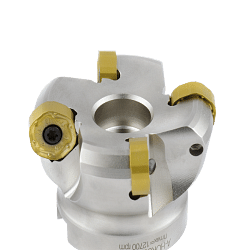

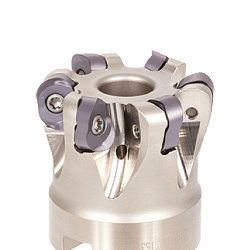

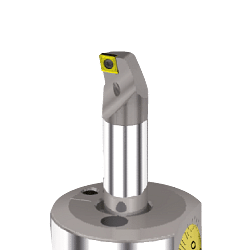

CNC face milling cutters are tools designed to remove material from a flat surface, creating a smooth and uniform finish. These tools are mainly used in computer numerical control (CNC) machines, which offer high precision and repeatability in machining processes. The inserts, on the other hand, are interchangeable components mounted on the cutters, made of durable materials such as tungsten carbide, which guarantee long life and optimum performance.

Operation and applications of CNC face milling cutters

CNC face milling cutters operate through a rotary motion, removing layers of material from the surface of the workpiece. This process is essential to prepare surfaces for further machining or to achieve the desired finish. The applications of face milling cutters are varied and include the machining of metals, alloys, plastics and other industrial materials. Due to their versatility, these milling cutters are used in industries such as automotive, aerospace, machinery manufacturing and many others.

Advantages of using CNC face milling cutters and inserts

The adoption of CNC face milling cutters and inserts offers many advantages to machine shops. Firstly, the precision of CNC machines allows for perfectly smooth surfaces, minimising the need for further machining. Furthermore, the use of interchangeable inserts optimises production costs, as only the worn part of the tool can be replaced, rather than the entire cutter. This results in greater operational efficiency and reduced machine downtime.

Selection of CNC face milling cutters and inserts

The choice of CNC face milling cutters and inserts depends on several factors, including the material to be machined, the desired cutting speed and the required surface finish. It is essential to select high quality tools, designed to withstand mechanical and thermal stress during the machining process. In addition, it is important to consider the geometry of the insert, which affects the cutting capacity and tool life.

Maintenance and care of CNC face milling cutters and inserts

To ensure optimum performance and long life of CNC face milling cutters and inserts, proper maintenance practices are essential. This includes regular cleaning of tools to remove material residue and regular checking of inserts for wear. In addition, it is advisable to use appropriate lubricants to reduce friction and heat generated during the machining process, thus preventing tool damage.

Frequently asked questions about CNC face milling cutters and inserts

1. What are the most common materials used for CNC face milling cutter inserts?

CNC milling cutter inserts are commonly made of tungsten carbide, ceramic and cermet, materials known for their resistance to wear and high temperatures.

2. How can I determine the optimum cutting speed for my application?

The optimum cutting speed depends on the workpiece material, the type of insert used and the specifications of the CNC machine. It is advisable to consult the tool manufacturer's guidelines to obtain the correct parameters.

3. What are the signs of insert wear that indicate the need for replacement?

Signs of insert wear include a reduction in surface finish quality, increased vibration during machining and an increase in tool temperature.

4. Can CNC face milling cutters be used on non-metallic materials?

Yes, CNC face milling cutters can be used on a wide range of materials, including plastic, wood and composites, as long as the appropriate tools and machining parameters are selected.

5. What are the current trends in CNC face milling cutters and inserts?

Current trends include the development of inserts with advanced coatings to improve wear resistance and the integration of monitoring technologies to optimise machining processes.

Conclusion

CNC face milling cutters and inserts are indispensable tools for machine shops aiming to improve machining efficiency and quality. Thanks to their precision and versatility, these tools enable perfectly machined surfaces, reducing production time and operating costs. The careful choice of tools, combined with proper maintenance practices, ensures optimal performance and long tool life, contributing to the success of machining operations.

Read More Read LessIn the world of machining, efficiency and precision are key elements in ensuring the quality of the end product. CNC face milling cutters and inserts are essential tools for machine shops wishing to optimise production processes and achieve perfectly machined surfaces. In this article, we will explore in detail what CNC face milling cutters and inserts are, what they are used for, how they are used and what advantages they offer. In addition, we will answer frequently asked questions to provide a comprehensive and detailed overview.

Introduction to CNC face milling cutters and inserts

CNC face milling cutters are tools designed to remove material from a flat surface, creating a smooth and uniform finish. These tools are mainly used in computer numerical control (CNC) machines, which offer high precision and repeatability in machining processes. The inserts, on the other hand, are interchangeable components mounted on the cutters, made of durable materials such as tungsten carbide, which guarantee long life and optimum performance.

Operation and applications of CNC face milling cutters

CNC face milling cutters operate through a rotary motion, removing layers of material from the surface of the workpiece. This process is essential to prepare surfaces for further machining or to achieve the desired finish. The applications of face milling cutters are varied and include the machining of metals, alloys, plastics and other industrial materials. Due to their versatility, these milling cutters are used in industries such as automotive, aerospace, machinery manufacturing and many others.

Advantages of using CNC face milling cutters and inserts

The adoption of CNC face milling cutters and inserts offers many advantages to machine shops. Firstly, the precision of CNC machines allows for perfectly smooth surfaces, minimising the need for further machining. Furthermore, the use of interchangeable inserts optimises production costs, as only the worn part of the tool can be replaced, rather than the entire cutter. This results in greater operational efficiency and reduced machine downtime.

Selection of CNC face milling cutters and inserts

The choice of CNC face milling cutters and inserts depends on several factors, including the material to be machined, the desired cutting speed and the required surface finish. It is essential to select high quality tools, designed to withstand mechanical and thermal stress during the machining process. In addition, it is important to consider the geometry of the insert, which affects the cutting capacity and tool life.

Maintenance and care of CNC face milling cutters and inserts

To ensure optimum performance and long life of CNC face milling cutters and inserts, proper maintenance practices are essential. This includes regular cleaning of tools to remove material residue and regular checking of inserts for wear. In addition, it is advisable to use appropriate lubricants to reduce friction and heat generated during the machining process, thus preventing tool damage.

Frequently asked questions about CNC face milling cutters and inserts

1. What are the most common materials used for CNC face milling cutter inserts?

CNC milling cutter inserts are commonly made of tungsten carbide, ceramic and cermet, materials known for their resistance to wear and high temperatures.

2. How can I determine the optimum cutting speed for my application?

The optimum cutting speed depends on the workpiece material, the type of insert used and the specifications of the CNC machine. It is advisable to consult the tool manufacturer's guidelines to obtain the correct parameters.

3. What are the signs of insert wear that indicate the need for replacement?

Signs of insert wear include a reduction in surface finish quality, increased vibration during machining and an increase in tool temperature.

4. Can CNC face milling cutters be used on non-metallic materials?

Yes, CNC face milling cutters can be used on a wide range of materials, including plastic, wood and composites, as long as the appropriate tools and machining parameters are selected.

5. What are the current trends in CNC face milling cutters and inserts?

Current trends include the development of inserts with advanced coatings to improve wear resistance and the integration of monitoring technologies to optimise machining processes.

Conclusion

CNC face milling cutters and inserts are indispensable tools for machine shops aiming to improve machining efficiency and quality. Thanks to their precision and versatility, these tools enable perfectly machined surfaces, reducing production time and operating costs. The careful choice of tools, combined with proper maintenance practices, ensures optimal performance and long tool life, contributing to the success of machining operations.