< Workshop equipment Industrial cable winders

Professional industrial cable reels are a key element for efficiency and safety in machine shops. These devices, designed to manage and organise cables of various lengths and thicknesses, are essential to ensure an orderly and unobstructed working environment. In this in-depth look, we will explore in detail what industrial cable reels are, how they work, their advantages and best practices for their use.

Introduction to industrial cable reels

Industrial cable reels are mechanical devices designed to wind and unwind cables in an orderly and safe manner. They are commonly used in industrial environments and machine shops where cable management is crucial for efficient day-to-day operations. These tools not only help maintain order, but also reduce the risk of accidents caused by cables scattered on the floor.

Operation and types of cable reels

Industrial cable reels can be manual or automatic. Manual models require operator intervention to wind the cable, while automatic ones use a spring or motorised mechanism to rewind the cable automatically. The types also vary depending on the type of cable they have to handle, such as electrical cables, compressed air cables or hydraulic cables.

Advantages of using industrial cable reels

The use of industrial cable reels offers numerous advantages. Firstly, they improve safety by reducing the risk of tripping over scattered cables. In addition, they protect cables from physical damage, prolonging their lifespan. Another significant benefit is operational efficiency: with cables always in order, the time spent searching for and handling cables is significantly reduced, increasing overall productivity.

Practical applications in machine shops

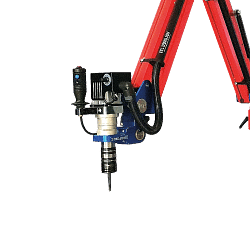

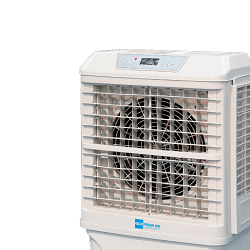

In machine shops, cable reels are used for a variety of applications. They can be used to manage power tool cables, welding machine cables, or compressed air hoses. Their versatility makes them suitable for different operational needs, contributing to a more organised and safer working environment.

How to choose the right cable reel

Choosing the right cable reel depends on several factors, including the type of cable to be handled, the length of the cable, and the environment of use. It is important to consider the cable reel's load capacity and its resistance to environmental conditions, such as humidity and temperature extremes. In addition, ease of installation and maintenance are crucial aspects to evaluate.

Maintenance and care of cable reels

To ensure a long service life and optimal operation, regular maintenance of cable reels is essential. This includes periodic cleaning, lubrication of moving parts and inspection of cables for signs of wear or damage. Proper maintenance not only prolongs the life of the cable reel, but also ensures operational safety.

Frequently asked questions about industrial cable reels

1. What is the difference between a manual and an automatic cable reel?

Manual cable reels require operator intervention to wind the cable, whereas automatic reels use a spring or motorised mechanism to rewind the cable automatically.

2. Can cable reels be used outdoors?

Yes, but it is important to choose a model designed to withstand outdoor environmental conditions, such as humidity and extreme temperatures.

3. How do I know if a cable reel is suitable for my type of cable?

Check the manufacturer's technical specifications to ensure that the cable reel is compatible with the type and length of cable you intend to use.

4. What are the signs of wear and tear to look for in cables?

Signs of wear and tear include cracks, discolouration, or exposed wires. It is important to replace damaged cables immediately to avoid safety risks.

5. Can a damaged cable reel be repaired?

It depends on the type of damage. Some components can be replaced, but in the case of significant structural damage, it may be cheaper to replace the entire device.

Conclusion

Professional industrial cable reels are indispensable tools for machine shops, contributing to a safer and more organised working environment. Their ability to effectively manage cables reduces the risk of accidents and improves operational efficiency. Choosing the right cable reel and keeping it in good condition is essential to maximise the benefits of these devices. With a thorough understanding of their features and benefits, workshops can optimise their operations and ensure a safer and more productive working environment.

Read More Read Less