Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

02.927371

- Supporting big orders

02.38298620

-

info@linkindustrialtools.it

- Request assistance with form

Or contact us with the chat in the lower right corner

< Workshop equipment

- Home

- Workshop equipment

- Control knobs

Control knobs

Handwheels, knobs and cranks: essential elements for the mechanical industry

In the vast landscape of the mechanical industry, handwheels, knobs and cranks are key components that, although often overlooked, play a crucial role in the efficient operation of machinery and equipment. These seemingly simple elements are designed to ensure precision, control and safety in the daily operations of machine shops. In this in-depth look, we will explore in detail what these components are, what they are used for, how they are used and what benefits they offer, while also answering the most frequently asked questions in the industry.

Handwheels: precision and control at your fingertips

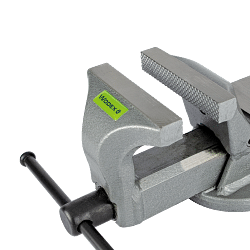

Handwheels are manual control devices used to precisely adjust the position of a mechanical component. Usually made of durable materials such as steel or aluminium, handwheels are designed to provide a secure and comfortable grip, allowing the operator to apply the necessary force without undue effort. Their ergonomic shape and non-slip surface are designed to ensure optimal control even in difficult working conditions.

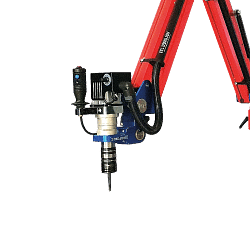

The main use of handwheels is in machine tools, where they are used to adjust the position of tables, slides and other moving components. Because of their ability to offer precise control, handwheels are essential for operations requiring high accuracy, such as milling and turning. Their versatility also makes them suitable for applications in areas such as industrial automation and robotics.

Knobs: ergonomics and safety at the service of the operator

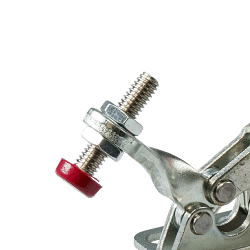

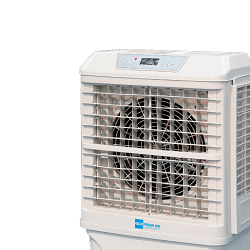

Handles are components designed to improve the ergonomics and safety of manual operations. Available in a wide range of shapes and sizes, knobs are used to operate valves, levers and other control devices. Their design takes into account the needs of the operator, providing a comfortable grip and reducing the risk of fatigue during prolonged use.

A key aspect of the knobs is their ability to improve operational safety. Thanks to non-slip materials and ergonomic designs, the handles reduce the risk of accidents caused by slipping or improper gripping. In addition, many handles are equipped with locking mechanisms that prevent accidental operation, providing an additional level of safety in critical operations.

Crank handles: power and versatility for dynamic applications

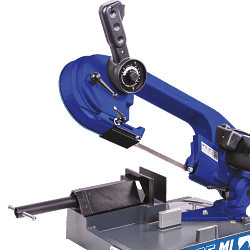

Hand cranks are mechanical instruments used to convert rotary motion into linear motion, or vice versa. This makes them particularly useful in applications requiring power transmission and motion control. Crank handles are commonly used in industrial machinery, agricultural equipment and lifting devices, where their ability to amplify the force applied by the operator is crucial.

The versatility of cranks is reflected in their ability to adapt to a wide range of applications. They can be used to operate lifting mechanisms, adjust the tension of belts and chains, or control the movement of moving components. Due to their robustness and reliability, crank handles are an ideal choice for applications requiring high strength and durability.

Advantages of using handwheels, knobs and cranks

The adoption of handwheels, knobs and cranks in machine shops offers numerous advantages that help improve operational efficiency and safety. Among the main benefits, we can highlight:

1. Precision and control: thanks to their ergonomic design and quality materials, these components allow precise control of operations, minimising errors and improving the quality of work.

2. Operational safety: the use of non-slip materials and locking mechanisms reduces the risk of accidents, protecting the operator and ensuring a safer working environment.

3. Versatility: the ability to adapt to different applications makes these components a flexible choice for a wide range of industries.

4. Durability and reliability: made from high-quality materials, handwheels, knobs and cranks offer long life and superior reliability, reducing maintenance and replacement costs.

5. Operational efficiency: by improving ergonomics and reducing operator fatigue, these components contribute to increased productivity and overall efficiency of operations.

Frequently asked questions about handwheels, knobs and cranks

In the context of machine shops, questions often arise regarding the use and maintenance of handwheels, knobs and cranks. Below, we answer some of the most common questions:

- What are the most common materials used in the production of these components?

The most common materials include steel, aluminium and reinforced plastic. The choice of material depends on the specific application and the requirements for strength and durability.

- How are handwheels, knobs and cranks maintained?

Maintenance of these components is generally simple and consists of regular cleaning and lubrication of moving parts. It is important to periodically inspect the components for signs of wear or damage.

- Can these components be customised for specific applications?

Yes, many manufacturers offer customisation options to adapt handwheels, knobs and cranks to specific application requirements, such as size, shape and materials.

- What are the main considerations when choosing these components for a specific application?

Key considerations include compatibility with the application, required strength and durability, ergonomics and operational safety.

- What are the emerging trends in the design of handwheels, knobs and cranks?

Emerging trends include the use of advanced materials to improve strength and reduce weight, and the integration of smart technologies to improve control and safety.

In conclusion, handwheels, knobs and cranks are essential components that offer numerous benefits to machine shops. Their ability to improve precision, safety and operational efficiency makes them an indispensable choice for a wide range of industrial applications. Investing in high quality components and maintaining them properly can lead to significant improvements in productivity and work safety.

Read More Read LessIn the vast landscape of the mechanical industry, handwheels, knobs and cranks are key components that, although often overlooked, play a crucial role in the efficient operation of machinery and equipment. These seemingly simple elements are designed to ensure precision, control and safety in the daily operations of machine shops. In this in-depth look, we will explore in detail what these components are, what they are used for, how they are used and what benefits they offer, while also answering the most frequently asked questions in the industry.

Handwheels: precision and control at your fingertips

Handwheels are manual control devices used to precisely adjust the position of a mechanical component. Usually made of durable materials such as steel or aluminium, handwheels are designed to provide a secure and comfortable grip, allowing the operator to apply the necessary force without undue effort. Their ergonomic shape and non-slip surface are designed to ensure optimal control even in difficult working conditions.

The main use of handwheels is in machine tools, where they are used to adjust the position of tables, slides and other moving components. Because of their ability to offer precise control, handwheels are essential for operations requiring high accuracy, such as milling and turning. Their versatility also makes them suitable for applications in areas such as industrial automation and robotics.

Knobs: ergonomics and safety at the service of the operator

Handles are components designed to improve the ergonomics and safety of manual operations. Available in a wide range of shapes and sizes, knobs are used to operate valves, levers and other control devices. Their design takes into account the needs of the operator, providing a comfortable grip and reducing the risk of fatigue during prolonged use.

A key aspect of the knobs is their ability to improve operational safety. Thanks to non-slip materials and ergonomic designs, the handles reduce the risk of accidents caused by slipping or improper gripping. In addition, many handles are equipped with locking mechanisms that prevent accidental operation, providing an additional level of safety in critical operations.

Crank handles: power and versatility for dynamic applications

Hand cranks are mechanical instruments used to convert rotary motion into linear motion, or vice versa. This makes them particularly useful in applications requiring power transmission and motion control. Crank handles are commonly used in industrial machinery, agricultural equipment and lifting devices, where their ability to amplify the force applied by the operator is crucial.

The versatility of cranks is reflected in their ability to adapt to a wide range of applications. They can be used to operate lifting mechanisms, adjust the tension of belts and chains, or control the movement of moving components. Due to their robustness and reliability, crank handles are an ideal choice for applications requiring high strength and durability.

Advantages of using handwheels, knobs and cranks

The adoption of handwheels, knobs and cranks in machine shops offers numerous advantages that help improve operational efficiency and safety. Among the main benefits, we can highlight:

1. Precision and control: thanks to their ergonomic design and quality materials, these components allow precise control of operations, minimising errors and improving the quality of work.

2. Operational safety: the use of non-slip materials and locking mechanisms reduces the risk of accidents, protecting the operator and ensuring a safer working environment.

3. Versatility: the ability to adapt to different applications makes these components a flexible choice for a wide range of industries.

4. Durability and reliability: made from high-quality materials, handwheels, knobs and cranks offer long life and superior reliability, reducing maintenance and replacement costs.

5. Operational efficiency: by improving ergonomics and reducing operator fatigue, these components contribute to increased productivity and overall efficiency of operations.

Frequently asked questions about handwheels, knobs and cranks

In the context of machine shops, questions often arise regarding the use and maintenance of handwheels, knobs and cranks. Below, we answer some of the most common questions:

- What are the most common materials used in the production of these components?

The most common materials include steel, aluminium and reinforced plastic. The choice of material depends on the specific application and the requirements for strength and durability.

- How are handwheels, knobs and cranks maintained?

Maintenance of these components is generally simple and consists of regular cleaning and lubrication of moving parts. It is important to periodically inspect the components for signs of wear or damage.

- Can these components be customised for specific applications?

Yes, many manufacturers offer customisation options to adapt handwheels, knobs and cranks to specific application requirements, such as size, shape and materials.

- What are the main considerations when choosing these components for a specific application?

Key considerations include compatibility with the application, required strength and durability, ergonomics and operational safety.

- What are the emerging trends in the design of handwheels, knobs and cranks?

Emerging trends include the use of advanced materials to improve strength and reduce weight, and the integration of smart technologies to improve control and safety.

In conclusion, handwheels, knobs and cranks are essential components that offer numerous benefits to machine shops. Their ability to improve precision, safety and operational efficiency makes them an indispensable choice for a wide range of industrial applications. Investing in high quality components and maintaining them properly can lead to significant improvements in productivity and work safety.