< Workshop equipment Accessories for lathes

Accessories for CNC lathes: a world of precision and innovation

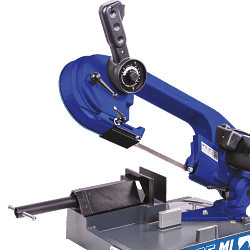

At the heart of modern machine shops, CNC lathes represent one of the most advanced and versatile technologies. Thanks to their ability to perform complex machining operations with millimetre precision, these machines have become indispensable for industrial production. However, in order to exploit the full potential of a CNC lathe, it is essential to have the right accessories. Accessories for CNC lathes not only improve the efficiency and quality of work, but also expand the machining possibilities, allowing a wider range of projects to be tackled.

The importance of CNC lathe accessories

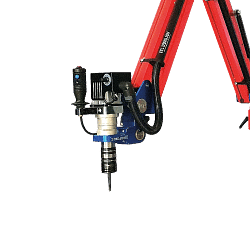

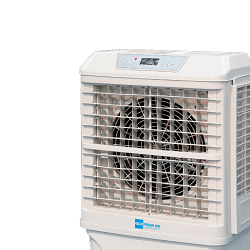

CNC lathe accessories are additional components that integrate with the main machine to optimise turning operations. These accessories can include spindles, tailstocks, cutting tools, tool holders, cooling systems and more. Each accessory has a specific function and contributes to improving the precision, speed and safety of operations.

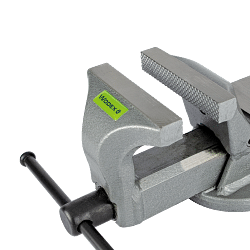

For example, spindles are essential for clamping workpieces. A high quality spindle ensures a firm and stable grip, reducing vibration and improving the surface finish of the workpiece. Tailstocks, on the other hand, support the workpiece during machining, preventing deformation and ensuring greater dimensional accuracy.

Advantages of using accessories for CNC lathes

There are several advantages to using suitable accessories for CNC lathes. Firstly, it improves the quality of the final product. Accessories such as precision cutting tools and advanced cooling systems enable smooth surfaces and close tolerances, minimising the need for subsequent machining.

Secondly, accessories increase operational efficiency. Automatic tool holders and quick tool change systems reduce machine downtime, allowing rapid changeover from one operation to another. This translates into increased productivity and reduced operating costs.

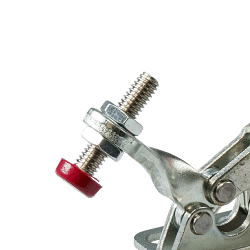

Finally, the use of appropriate accessories improves safety at work. Safe clamping systems and tool guards reduce the risk of accidents, protecting operators and prolonging machine life.

How to choose the right accessories for your CNC lathe

The choice of accessories for CNC lathes depends on several factors, including the type of machining to be performed, the materials to be machined and the specifications of the machine. It is important to carefully assess your production needs and consult experts in the field to find the most suitable accessories.

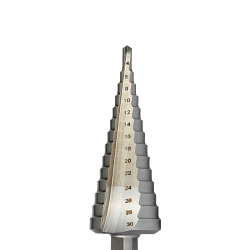

For example, if you mainly work with hard materials such as stainless steel, it is advisable to invest in tungsten carbide cutting tools, known for their wear resistance and ability to maintain a sharp edge even at high temperatures. For machining softer materials, such as aluminium, high-speed steel tools may be sufficient.

Frequently asked questions about CNC lathe accessories

1. What are the essential accessories for a CNC lathe?

Essential accessories include spindles, tailstocks, cutting tools, tool holders and cooling systems. However, the choice depends on the specific machining requirements.

2. How can I improve the precision of my CNC lathe?

Using high-quality accessories, such as precision spindles and sharp cutting tools, is essential to improve precision. In addition, regular maintenance of the machine and accessories helps to maintain optimum performance.

3. Are CNC lathe accessories universal?

Not all accessories are universal. It is important to check compatibility with your specific model of CNC lathe. Consulting the manufacturer's manual or an expert in the field can help you make the right choice.

4. What are the advantages of quick tool change systems?

Quick tool change systems reduce machine downtime and increase productivity. They allow you to quickly switch from one operation to another without having to manually disassemble and reassemble tools.

5. How can I ensure safety when using a CNC lathe?

Using safety accessories, such as tool guards and safe clamping systems, is essential to prevent accidents. In addition, it is important to follow standard operating procedures and provide proper training for operators.

Conclusions

CNC lathe accessories are crucial components that can make the difference between mediocre and high-quality machining. Investing in quality accessories not only improves the accuracy and efficiency of operations, but also ensures a safer working environment. With a wide range of options available on the market, it is essential to carefully assess your needs and choose the accessories that best suit the specifications of your CNC lathe. In this way, machine shops can exploit the full potential of their machinery and remain competitive in an ever-changing industry.

Read More Read Less