< Turning tools Negative and positive turning inserts

Turning inserts: a complete guide for the machine industry

In the world of mechanical engineering, efficiency and precision are key elements for success. Turning inserts, both negative and positive, are essential components for optimising metalworking processes. These tools, if chosen and used correctly, can significantly improve the quality of the end product and reduce production time. In this in-depth look, we will explore in detail what turning inserts are, how they work, their advantages and best practices for their use.

What are turning inserts?

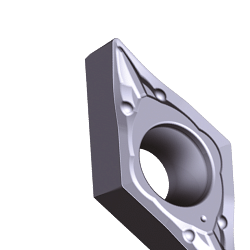

Turning inserts are interchangeable tools used in metalworking machine tools. They are designed to remove material from a workpiece, giving it the desired shape. Inserts can be classified into two main categories: negative and positive. The difference between these two types lies mainly in the rake angle, which affects the way the insert interacts with the material.

Negative inserts: strength and durability

Negative turning inserts are characterised by a zero or negative rake angle. This design gives them greater robustness, making them ideal for heavy-duty applications and machining hard materials. Their robust design allows them to withstand high loads and maintain stability during cutting. However, they require more machine power and can generate more heat during operation.

Positive inserts: precision and finish

Positive turning inserts, on the other hand, have a positive rake angle. This design reduces cutting resistance, allowing smoother and more precise machining. They are particularly suitable for finishing and machining softer materials. Positive inserts offer better surface quality and require less power, but may be less resistant than their negative counterparts.

Advantages of using turning inserts

The adoption of both negative and positive turning inserts offers numerous benefits to machine shops. Some of the main benefits include:

1. Production efficiency: Interchangeable inserts reduce machine downtime, as they can be replaced quickly without having to remove the entire tool.

2. Flexibility: The availability of a wide range of inserts allows adaptation to different applications and materials, enhancing the versatility of turning operations.

3. Product quality: Turning inserts guarantee a high quality surface finish, reducing the need for further machining.

4. Cost reduction: The use of application-specific inserts optimises material consumption and reduces tool wear, lowering overall operating costs.

How to choose the right turning inserts

Choosing the right turning inserts depends on several factors, including the material to be machined, the type of operation and the specifications of the machine tool. Here are some aspects to consider:

- Workpiece material: Different materials require inserts with specific characteristics. For example, for hard materials such as stainless steel, negative inserts are often preferred for their toughness.

- Type of machining: For roughing operations, negative inserts are generally more suitable, while for finishing, positive inserts offer better surface quality.

- Machine condition: The power and stability of the machine tool influence the choice of insert. More powerful machines can handle negative inserts, while less powerful machines might benefit from positive inserts.

Frequently asked questions about turning inserts

1. What is the average tool life of a turning insert?

The life of an insert depends on various factors, including the material being machined, cutting conditions and maintenance. In general, high quality inserts can last several hours of continuous machining.

2. Is it possible to resharpen turning inserts?

Most modern inserts are not designed to be reground. However, some special inserts can be resharpened to extend their service life.

3. How is the wear of an insert determined?

Wear on an insert can be identified by visible signs such as chips, cracks or a reduction in the quality of the machined surface. It is important to replace worn inserts to avoid damage to the workpiece or machine.

Conclusions

Turning inserts, both negative and positive, are indispensable tools for machine shops aiming to optimise their production processes. Choosing the right type of insert according to specific machining requirements can make all the difference in terms of efficiency, quality and cost. With a thorough understanding of their characteristics and applications, companies can exploit the full potential of these tools, improving their competitiveness in the industry.

Read More Read Less