< Turning tools Negative and positive turning inserts

In the world of machine shops, efficiency and precision are key elements in guaranteeing the quality of the end product. Turning inserts, both negative and positive, are an essential component in achieving these goals. These tools, when chosen and used correctly, can make all the difference in terms of performance and durability of turning operations.

Understanding turning inserts: a technical overview

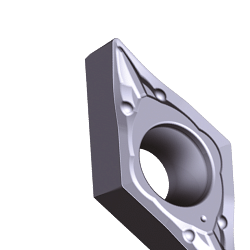

Turning inserts are interchangeable components used in machine tools to remove material from a workpiece. They are designed to withstand high mechanical and thermal stress while ensuring a high quality surface finish. Inserts are mainly divided into two categories: negative and positive. The choice between a negative or positive insert depends on various factors, including the type of material to be machined, the geometry of the workpiece and the specifications of the turning operation.

Negative inserts: robustness and durability

Negative turning inserts are characterised by a zero or negative rake angle. This configuration gives the insert greater strength, making it ideal for roughing operations and machining hard, tough materials. Negative inserts are often preferred because of their ability to withstand high loads and their long tool life, thus reducing the need for frequent replacement.

Positive inserts: precision and finish

In contrast, positive turning inserts have a positive rake angle, making them particularly suitable for finishing operations and machining softer materials. The geometry of positive inserts allows a reduction in cutting forces, improving the precision and quality of the machined surface. These inserts are ideal for applications requiring high dimensional accuracy and a flawless surface finish.

Advantages of using turning inserts

The adoption of turning inserts, both negative and positive, offers several advantages to machine shops. Firstly, the ability to easily change inserts reduces machine downtime, increasing overall productivity. In addition, the variety of insert geometries and materials available allows turning operations to be optimised for specific applications, improving efficiency and reducing operating costs.

Materials and coatings: choosing the right insert

The choice of insert material and coating is crucial to ensure optimum performance. Inserts are generally made of tungsten carbide, ceramic or cermet, each with specific properties that make them suitable for different applications. Coatings, such as titanium nitride or titanium carbonitride, further improve the wear resistance and tool life of the insert, enabling it to cope with demanding machining conditions.

Frequently asked questions about turning inserts

1. What is the main difference between negative and positive inserts?

Negative inserts are more robust and suitable for roughing operations, while positive inserts offer a better surface finish and are ideal for precision operations.

2. How do I choose the right insert for my application?

The choice of insert depends on the material to be machined, the type of operation (roughing or finishing) and the specifications of the machine tool.

3. What are the most common insert materials?

Common materials include tungsten carbide, ceramic and cermet, each with unique properties for different applications.

4. How does the coating affect the durability of the insert?

Coatings improve the wear resistance and durability of the insert, allowing it to cope with more demanding working conditions.

5. Can the same insert be used for different materials?

Although some inserts can be versatile, it is advisable to choose a specific insert for each type of material to optimise performance.

Conclusion: the importance of the correct choice of inserts

In conclusion, the choice of turning inserts, both negative and positive, is a crucial aspect for machine shops aiming to optimise their operations. By understanding the differences between the various types of inserts and their specific applications, it is possible to improve efficiency, reduce costs and ensure superior end-product quality. Investing in the right technology and staff training is crucial to remain competitive in an ever-changing industry.

Read More Read Less