< Lubricants for machine tools Accessories for cooling lubricants

Volumetric mixers for metalworking fluids are an essential component in modern machine shops, where efficiency and precision are paramount. These devices are designed to ensure optimal mixing of metalworking fluids, thus improving the performance of machine tools and extending the life of cutting tools. In this in-depth article, we will explore in detail what metalworking fluid mixers are, how they work, their advantages and answer the most frequently asked questions on this topic.

What are metalworking fluid mixers?

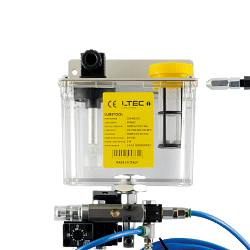

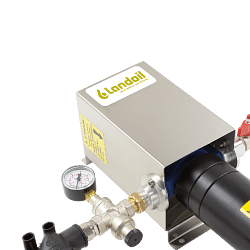

Positive displacement coolant mixers are devices designed to precisely and consistently mix metalworking fluids with water, creating a homogenous solution that is used in machine tools. These mixers are essential to ensure that the concentration of the metalworking fluid is always optimal, preventing problems such as corrosion of tools or premature machine wear.

How do volumetric mixers work?

The operation of volumetric mixers is based on a simple but effective principle: volumetric mixing. This process involves the precise measurement of metalworking fluid and water volumes, which are then combined to obtain the desired mixture. Volumetric mixers are equipped with pumps and valves that regulate the flow of liquids, ensuring constant and uniform mixing.

Advantages of using volumetric mixers

The adoption of volumetric mixers for metalworking fluids offers numerous advantages to machine shops. Firstly, they ensure precise mixing, reducing the risk of human error and improving the quality of the end product. They also help reduce operating costs, as they optimise the use of metalworking fluids and minimise waste. Another significant benefit is the reduction of downtime, as correct mixing reduces tool and machine wear.

Practical applications in machine shops

In machine shops, metalworking fluid mixers are used in various operations, such as milling, turning and drilling. In each of these operations, proper lubrication and cooling of the tools is crucial to achieve high-quality results. Volumetric mixers ensure that the metalworking fluid mixture is always at the right concentration, thus improving machining efficiency and precision.

Frequently asked questions about metalworking fluid mixers

1. What is the difference between a positive displacement mixer and a proportional mixer?

Volumetric mixers measure the volumes of liquids to be mixed, whereas proportional mixers regulate mixing according to a predefined ratio. Volumetric mixers offer greater mixing precision.

2. How is a volumetric mixer maintained?

Maintenance of positive displacement mixers is relatively simple and includes regular cleaning of components, checking valves and pumps, and checking calibration to ensure accurate mixing.

3. What are the signs of a volumetric mixer malfunction?

Signs of a malfunction may include uneven mixing, liquid leaks, or increased metalworking fluid consumption. It is important to act promptly to avoid damage to machine tools.

4. Can the mixing process be automated?

Yes, many modern volumetric mixers are equipped with automation systems that allow the mixing process to be programmed and monitored, further improving operational efficiency.

5. What are the criteria for choosing a volumetric mixer?

The choice of a volumetric mixer depends on several factors, including the type of processing, the production volume, and the specific needs of the workshop. It is important to assess the mixer's capacity, ease of use and compatibility with the metalworking fluids used.

Conclusions

Volumetric mixers for metalworking fluids are indispensable tools in modern machine shops, where precision and efficiency are essential. Thanks to their ability to ensure optimal mixing, these devices help to improve the quality of machining operations, reduce operating costs and extend the service life of machine tools. Investing in a quality volumetric mixer is a strategic choice for any machine shop wishing to remain competitive in today's market.

Read More Read Less