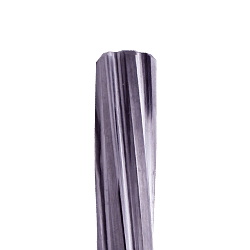

< Solid cutting tools HSS drills

Professional HSS metal drill bits are an essential tool for machine shops and anyone working in the metalworking industry. These drills, made of High-Speed Steel, are designed to guarantee precision, efficiency and durability, even under the most demanding working conditions. In this in-depth look, we will explore the distinctive features of HSS drills, their optimal use, the advantages they offer and answer some of the most frequently asked questions on this topic.

Features of HSS drills for metal drilling

HSS drills are known for their ability to maintain high resistance to heat and wear, making them ideal for drilling hard metals such as steel, cast iron and metal alloys. The composition of super high-speed steel includes elements such as tungsten, molybdenum, chromium and vanadium, which give the drills superior hardness and strength. These characteristics allow HSS drills to operate at high speeds without losing their sharpness, guaranteeing precise and clean holes.

Optimum use of HSS drills

To achieve the best results with HSS drills, it is essential to follow a few operational guidelines. First of all, it is important to select the right drill according to the material to be drilled and the diameter of the desired hole. In addition, the use of a suitable lubricant when drilling can reduce friction and heat generated, prolonging the life of the drill bit. It is also advisable to use an appropriate rotational speed for the specific material, as excessive speed can cause overheating and premature wear of the drill bit.

Advantages of HSS drills

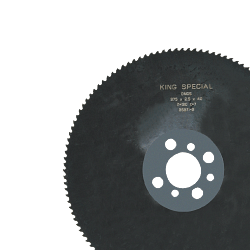

The adoption of HSS drills offers numerous advantages for machine shops. In addition to their strength and durability, these drills guarantee greater precision when drilling, reducing the risk of errors and production waste. Their ability to operate at high speeds increases productivity, reducing machining times. Furthermore, HSS drills are available in a wide range of sizes and shapes, allowing them to tackle a variety of applications and materials.

Frequently asked questions about HSS drills

One of the most common questions concerns the difference between HSS drills and tungsten carbide drills. While carbide drills offer greater hardness, HSS drills are more versatile and less brittle, making them suitable for a wider range of applications. Another frequent question concerns the maintenance of HSS drills. To keep the drills in optimal condition, it is advisable to sharpen them regularly and store them in a dry environment to prevent corrosion.

Innovations and developments in the field of HSS drills

In recent years, the HSS drill bit sector has seen significant innovations, with the introduction of advanced coatings such as titanium nitride (TiN) and aluminium titanium nitride (AlTiN). These coatings further improve heat and wear resistance, extending drill bit life and improving drilling performance. In addition, advanced manufacturing technologies have enabled drills with optimised geometries to reduce friction and improve chip evacuation.

Conclusion

Professional HSS metal drill bits are an excellent choice for machine shops looking for reliable, high-performance tools. Thanks to their strength, versatility and precision, these drills continue to be a mainstay in metalworking. By adopting the right operating practices and proper maintenance, HSS drills can offer exceptional performance and contribute to successful drilling operations.

Read More Read Less