< Solid cutting tools HSS and Super Speed Steel Cutters

HSS and super high-speed steel cutters represent a fundamental element in the machining landscape, offering high performance and a versatility that makes them indispensable in many industrial applications. These cutting tools are designed for precision, efficiency and durability, essential features to meet the needs of modern machine shops.

Introduction to HSS and Super Speed Steel cutters

HSS milling cutters, which stands for High-Speed Steel, and super high-speed steel milling cutters are cutting tools used mainly for metalworking. Their high-speed steel composition allows them to operate at high speeds without compromising the quality of the cut. This type of steel is known for its resistance to wear and thermal deformation, making it ideal for applications requiring precision and reliability.

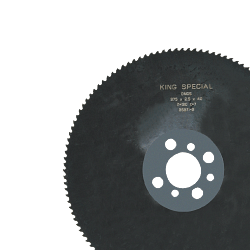

Distinctive features of HSS milling cutters

HSS milling cutters are distinguished by their ability to maintain high hardness even at high temperatures, a characteristic that makes them particularly suitable for high-speed machining. Their composition includes elements such as tungsten, molybdenum, chromium and vanadium, which contribute to improved wear resistance and toughness. These properties enable HSS cutters to cope with difficult-to-machine materials such as alloy steels and cast irons.

Advantages of using super high-speed steel cutters

Super high-speed steel offers several advantages over other cutting tool materials. First of all, its ability to maintain hardness at high temperatures allows machining times to be reduced, increasing productivity. In addition, its resistance to wear extends tool life, reducing replacement and maintenance costs. These characteristics make super high-speed steel cutters an economical and sustainable choice for machine shops.

Applications of HSS and super speed steel cutters

HSS and super high-speed steel cutters are used in a wide range of industrial applications. They are used for milling, drilling and turning operations on ferrous and non-ferrous metals. Due to their versatility, they can be used in sectors such as automotive, aerospace, mould and die making and machine construction. Their ability to work precisely on hard, tough materials makes them indispensable for the production of complex, high-quality components.

How to choose the right cutter for your application

Choosing the right cutter depends on several factors, including the type of material to be machined, the desired cutting speed and the required surface finish. It is also important to consider the geometry of the cutter, which can influence the quality of the cut and the tool life. Cutters with more teeth, for example, offer a smoother finish, while those with fewer teeth are better suited to removing large amounts of material.

Maintenance and care of HSS and super speed steel cutters

To ensure optimum performance and prolong the life of HSS and super high-speed steel cutters, it is essential to adopt proper maintenance practices. This includes regular cleaning of tools to remove machining residues and periodic sharpening to keep the cutting edge in optimum condition. In addition, it is important to store cutters in a dry and protected environment to prevent corrosion and accidental damage.

Frequently asked questions about HSS and super high-speed steel cutters

1. What is the difference between HSS cutters and carbide cutters?

HSS cutters are made of high-speed steel, whereas carbide cutters are made of tungsten carbide. Carbide cutters offer greater hardness and wear resistance, but are more brittle than HSS cutters.

2. Can I use HSS milling cutters on non-metallic materials?

Yes, HSS cutters can be used on non-metallic materials such as plastic and wood, but it is important to adjust the cutting speed and feed rate to avoid overheating and material damage.

3. How can I improve the lifetime of my HSS cutters?

To improve the lifetime of HSS cutters, it is advisable to use appropriate lubricants during machining, avoid excessive overloading and follow regular maintenance practices.

Conclusion

HSS and Super Speed Steel cutters are an effective and versatile solution for machining operations, offering high performance and long tool life. Their ability to operate at high speeds without compromising cutting quality makes them an ideal choice for machine shops looking to optimise productivity and reduce operating costs. With proper selection and maintenance, these cutters can contribute significantly to the success of industrial machining operations.

Read More Read Less