Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

+31(0)85-0471271

- Supporting big orders

02.38298620

-

info@linkindustrialtools.nl

- Request assistance with form

Or contact us with the chat in the lower right corner

< Lifting systems

- Home

- Lifting systems

- Manual chain hoists

Manual chain hoists

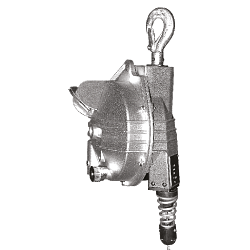

Manual chain hoists are an essential tool in machine shops and industries that need to lift heavy loads with precision and safety. These devices, known for their reliability and versatility, are designed to facilitate the lifting of heavy objects efficiently, while minimising the physical effort required of operators. In this in-depth look, we will explore in detail what manual chain hoists are, how they work, their advantages and practical applications in machine shops.

Understanding manual chain hoists

Manual chain hoists are mechanical devices used for lifting and lowering heavy loads. They work by means of a system of gears and chains that multiply the force applied by the operator, making it possible to lift loads that would otherwise be impossible to handle manually. The structure of a manual chain hoist consists mainly of a lifting chain, a manoeuvring chain, a load hook and a locking mechanism.

Operation and use

The operation of a manual chain hoist is relatively simple. The operator pulls the manoeuvring chain, which in turn drives a gear system inside the hoist. This gear system multiplies the force applied, allowing the load attached to the load hook to be lifted. Once the desired height is reached, the locking mechanism ensures that the load remains in place, guaranteeing the safety of the operation.

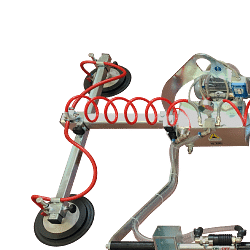

Manual chain hoists are widely used in machine shops for a variety of applications. They are ideal for lifting engines, machinery components and other heavy objects that require precision and control during lifting. Their ability to lift heavy loads with minimal physical effort makes them an indispensable tool for operators working in industrial environments.

Advantages of manual chain hoists

One of the main advantages of manual chain hoists is their simplicity and reliability. Being mechanical devices, they do not require electrical or hydraulic power, making them ideal for use in environments where access to power is limited. In addition, their robust and durable construction ensures a long service life, even under intensive use.

Another significant advantage is safety. Manual chain hoists are equipped with locking mechanisms that prevent accidental load release, reducing the risk of accidents at work. In addition, the ability to precisely control the movement of the load allows operators to position lifted objects with great accuracy, minimising the risk of damage to surrounding materials or equipment.

Practical applications in machine shops

In machine shops, manual chain hoists are used in a wide range of operations. They are commonly used for lifting and handling engines, transmissions and other heavy components during assembly and maintenance operations. Their ability to lift heavy loads with precision makes them particularly useful in assembly operations, where exact positioning of components is essential.

In addition, manual chain hoists are often used in welding and fabrication operations, where heavy materials such as sheet metal and metal structures need to be lifted and positioned. Their versatility and ease of use make them a valuable tool for operators working in complex and dynamic industrial environments.

Frequently asked questions about manual chain hoists

1. What is the lifting capacity of a manual chain hoist?

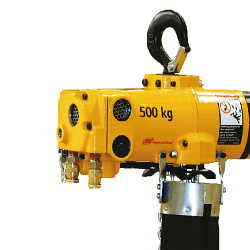

The lifting capacity of a manual chain hoist varies depending on the model and manufacturer. However, most manual chain hoists are designed to lift loads ranging from a few hundred kilograms to several tonnes.

2. How is a manual chain hoist maintained?

Maintenance of a manual chain hoist is essential to ensure its safety and efficiency. It is important to regularly inspect the lifting chain and manoeuvring chain for signs of wear or damage. In addition, it is advisable to periodically lubricate the gears and locking mechanisms to ensure smooth operation.

3. Are manual chain hoists suitable for outdoor use?

Yes, manual chain hoists can be used outdoors, provided they are adequately protected from the elements. It is important to ensure that the hoist is made of corrosion-resistant materials and that it is stored in a dry place when not in use.

4. What are the safety regulations for the use of manual chain hoists?

The use of manual chain hoists is subject to specific safety regulations that vary from country to country and region to region. It is essential that operators are properly trained and follow the safety guidelines provided by the manufacturer and the relevant authorities.

5. Can a manual chain hoist be used to lift people?

No, manual chain hoists are not designed for lifting persons. They are only intended for lifting material loads and improper use can lead to serious safety hazards.

In conclusion, manual chain hoists are indispensable tools in machine shops and many other industrial applications. Their ability to lift heavy loads with precision and safety makes them an ideal choice for operators seeking reliable and versatile solutions for their lifting needs. With proper maintenance and use, manual chain hoists can provide years of efficient and safe service.

Read More Read LessUnderstanding manual chain hoists

Manual chain hoists are mechanical devices used for lifting and lowering heavy loads. They work by means of a system of gears and chains that multiply the force applied by the operator, making it possible to lift loads that would otherwise be impossible to handle manually. The structure of a manual chain hoist consists mainly of a lifting chain, a manoeuvring chain, a load hook and a locking mechanism.

Operation and use

The operation of a manual chain hoist is relatively simple. The operator pulls the manoeuvring chain, which in turn drives a gear system inside the hoist. This gear system multiplies the force applied, allowing the load attached to the load hook to be lifted. Once the desired height is reached, the locking mechanism ensures that the load remains in place, guaranteeing the safety of the operation.

Manual chain hoists are widely used in machine shops for a variety of applications. They are ideal for lifting engines, machinery components and other heavy objects that require precision and control during lifting. Their ability to lift heavy loads with minimal physical effort makes them an indispensable tool for operators working in industrial environments.

Advantages of manual chain hoists

One of the main advantages of manual chain hoists is their simplicity and reliability. Being mechanical devices, they do not require electrical or hydraulic power, making them ideal for use in environments where access to power is limited. In addition, their robust and durable construction ensures a long service life, even under intensive use.

Another significant advantage is safety. Manual chain hoists are equipped with locking mechanisms that prevent accidental load release, reducing the risk of accidents at work. In addition, the ability to precisely control the movement of the load allows operators to position lifted objects with great accuracy, minimising the risk of damage to surrounding materials or equipment.

Practical applications in machine shops

In machine shops, manual chain hoists are used in a wide range of operations. They are commonly used for lifting and handling engines, transmissions and other heavy components during assembly and maintenance operations. Their ability to lift heavy loads with precision makes them particularly useful in assembly operations, where exact positioning of components is essential.

In addition, manual chain hoists are often used in welding and fabrication operations, where heavy materials such as sheet metal and metal structures need to be lifted and positioned. Their versatility and ease of use make them a valuable tool for operators working in complex and dynamic industrial environments.

Frequently asked questions about manual chain hoists

1. What is the lifting capacity of a manual chain hoist?

The lifting capacity of a manual chain hoist varies depending on the model and manufacturer. However, most manual chain hoists are designed to lift loads ranging from a few hundred kilograms to several tonnes.

2. How is a manual chain hoist maintained?

Maintenance of a manual chain hoist is essential to ensure its safety and efficiency. It is important to regularly inspect the lifting chain and manoeuvring chain for signs of wear or damage. In addition, it is advisable to periodically lubricate the gears and locking mechanisms to ensure smooth operation.

3. Are manual chain hoists suitable for outdoor use?

Yes, manual chain hoists can be used outdoors, provided they are adequately protected from the elements. It is important to ensure that the hoist is made of corrosion-resistant materials and that it is stored in a dry place when not in use.

4. What are the safety regulations for the use of manual chain hoists?

The use of manual chain hoists is subject to specific safety regulations that vary from country to country and region to region. It is essential that operators are properly trained and follow the safety guidelines provided by the manufacturer and the relevant authorities.

5. Can a manual chain hoist be used to lift people?

No, manual chain hoists are not designed for lifting persons. They are only intended for lifting material loads and improper use can lead to serious safety hazards.

In conclusion, manual chain hoists are indispensable tools in machine shops and many other industrial applications. Their ability to lift heavy loads with precision and safety makes them an ideal choice for operators seeking reliable and versatile solutions for their lifting needs. With proper maintenance and use, manual chain hoists can provide years of efficient and safe service.