< Lifting systems Jib cranes

Industrial jib cranes are a key element in the panorama of material handling equipment in machine shops. These tools, thanks to their versatility and robustness, are able to optimise production processes, improving efficiency and safety at work. In this in-depth look, we will explore in detail what industrial jib cranes are, how they work, their advantages and practical applications, while also answering frequently asked questions on this topic.

Introduction to industrial jib cranes

Industrial jib cranes are lifting devices designed to facilitate the handling of heavy loads in confined spaces. These cranes are characterised by a horizontal jib, called a 'jib', which is mounted on a vertical support. The jib can rotate around the support, allowing a wide coverage of the working area. Jib cranes can be wall-mounted or column-mounted, depending on the specific requirements of the working environment.

Operation and main components

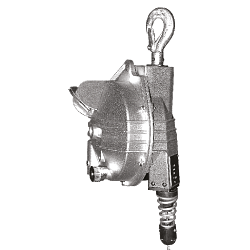

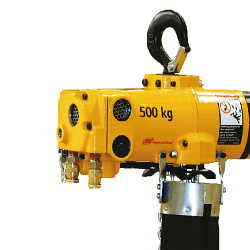

The operation of industrial jib cranes is based on a slewing and lifting system. The crane jib is equipped with a trolley that slides along its length, allowing the load to move. The trolley is connected to a hoist, which can be manual or electric, used to lift and lower the load. The rotation of the boom allows the load to be positioned in different areas of the workshop, making handling operations more flexible and efficient.

The main components of a jib crane include the vertical support, horizontal boom, trolley, hoist and control system. The vertical support can be fixed to the floor or wall, while the jib is designed to withstand heavy loads and ensure smooth rotation. The control system, which can be manual or automated, allows the operator to precisely manage the movement of the load.

Advantages of industrial jib cranes

The use of industrial jib cranes offers numerous advantages, making them an ideal choice for machine shops. One of the main benefits is their ability to optimise working space. Thanks to their compact design and rotatable design, these cranes can be installed in confined areas without compromising load handling capacity.

In addition, jib cranes improve safety at work. Manual handling of heavy loads can pose significant health risks to operators, such as musculoskeletal injuries. The use of a jib crane reduces the need for manual lifting, minimising the risk of injury.

Another significant advantage is the increase in operating efficiency. Jib cranes allow materials to be moved quickly and accurately, reducing downtime and improving overall workshop productivity. In addition, the ability to automate certain operations with electric hoists and advanced control systems helps to further optimise production processes.

Practical applications in machine shops

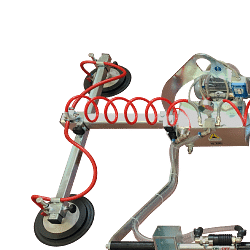

Industrial jib cranes find application in a wide range of areas within machine shops. They are particularly useful for handling heavy components, such as engines, equipment and raw materials. Due to their versatility, they can be used at different stages of the production process, from receiving raw materials to shipping finished products.

In addition, jib cranes are ideal for assembly and maintenance operations. The ability to precisely position components facilitates the assembly of complex machinery, while the ability to lift and move heavy equipment simplifies maintenance and repair operations.

Frequently asked questions about industrial jib cranes

1. What is the load capacity of a jib crane?

The load capacity of a jib crane varies depending on the model and technical specifications. In general, these cranes can lift loads ranging from a few hundred kilograms to several tonnes. It is important to choose a crane with a capacity adapted to the specific needs of the workshop.

2. What are the installation requirements for a jib crane?

The installation of a jib crane requires an accurate assessment of the available space and the structural conditions of the building. It is essential to ensure that the vertical support is securely fixed and that the jib can rotate freely without obstruction. In addition, it is important to consider the power supply required for electric hoists.

3. Do jib cranes require maintenance?

Yes, jib cranes require regular maintenance to ensure their proper functioning and the safety of operators. Maintenance includes inspection of mechanical components, lubrication of moving parts and checking the control system. It is advisable to follow the manufacturer's instructions and schedule regular maintenance.

4. Is it possible to customise a jib crane?

Many manufacturers offer the possibility of customising jib cranes according to specific customer requirements. Customisation can include jib length, load capacity, hoist type and control options. Customisation allows the crane's performance to be optimised for specific applications.

5. What are the safety regulations for using jib cranes?

The use of jib cranes is subject to specific safety regulations, which vary according to country and industry sector. It is essential to comply with local regulations and take appropriate safety measures, such as operator training and the use of personal protective equipment. Safety regulations aim to prevent accidents and ensure a safe working environment.

Conclusions

Industrial jib cranes are indispensable tools for machine shops due to their ability to improve operational efficiency and work safety. Their versatility and robustness make them suitable for a wide range of applications, from heavy material handling to the assembly of complex machinery. Choosing the right jib crane and ensuring it is properly maintained are key steps in optimising production processes and ensuring a safe and productive working environment.

Read More Read Less